What is Global Polyvinyl Butyral Market?

The Global Polyvinyl Butyral (PVB) Market is a significant segment within the chemical industry, primarily driven by its extensive applications in various sectors. PVB is a resin typically used in the production of laminated safety glass, which is a crucial component in the automotive and architectural industries. This material is known for its excellent adhesive properties, clarity, flexibility, and toughness, making it ideal for use in safety glass that requires impact resistance and sound insulation. The market for PVB is expanding due to the increasing demand for safety glass in vehicles and buildings, driven by safety regulations and the growing awareness of safety standards worldwide. Additionally, PVB is used in the production of photovoltaic panels, paints, glues, and inks, further broadening its market scope. The global market is characterized by a few dominant players who control a significant share of the market, and it is geographically diverse, with Asia-Pacific being the largest consumer region. The market's growth is supported by technological advancements and innovations in product applications, which continue to enhance the performance and efficiency of PVB in various uses.

High Molecular Weight Grade PVB Resin, Medium Molecular Weight Grade PVB Resin, Low Molecular Weight Grade PVB Resin, Modified PVB Resin in the Global Polyvinyl Butyral Market:

High Molecular Weight Grade PVB Resin, Medium Molecular Weight Grade PVB Resin, Low Molecular Weight Grade PVB Resin, and Modified PVB Resin are different types of PVB resins that cater to various applications based on their molecular weight and properties. High Molecular Weight Grade PVB Resin is known for its superior mechanical properties, including high tensile strength and impact resistance. This makes it particularly suitable for applications requiring durability and robustness, such as in the automotive and architectural sectors where safety and longevity are paramount. Medium Molecular Weight Grade PVB Resin strikes a balance between flexibility and strength, making it versatile for a range of applications, including laminated glass and coatings. It offers good adhesion and clarity, which are essential for maintaining the aesthetic and functional qualities of safety glass. Low Molecular Weight Grade PVB Resin, on the other hand, is characterized by its enhanced flexibility and ease of processing. This type of resin is often used in applications where ease of handling and processing are critical, such as in the production of films and coatings. Modified PVB Resin is tailored to meet specific requirements by altering its chemical structure to enhance certain properties like adhesion, flexibility, or compatibility with other materials. This customization allows for the development of specialized products that can meet the unique demands of different industries. The choice of PVB resin type depends on the specific requirements of the application, such as the desired balance between strength, flexibility, and processing ease. Each type of resin offers distinct advantages that can be leveraged to optimize performance in various end-use applications. The global market for these resins is driven by the growing demand for high-performance materials in industries such as automotive, construction, and renewable energy. As industries continue to evolve and innovate, the demand for specialized PVB resins is expected to grow, further diversifying the market and expanding its potential applications.

Automotive, Architectural, Photovoltaic, Paints, Glues, Ink, Others in the Global Polyvinyl Butyral Market:

The usage of Global Polyvinyl Butyral Market spans several key areas, including Automotive, Architectural, Photovoltaic, Paints, Glues, Ink, and others. In the automotive industry, PVB is primarily used in the production of laminated safety glass for windshields and windows. Its ability to hold glass together upon impact reduces the risk of injury, making it an essential component in vehicle safety. Additionally, PVB's sound-dampening properties contribute to a quieter cabin environment, enhancing passenger comfort. In the architectural sector, PVB is used in the production of laminated glass for buildings, providing safety, security, and sound insulation. Its use in architectural glass also enhances energy efficiency by reducing heat transfer, contributing to sustainable building practices. In the photovoltaic industry, PVB is used as an encapsulant material in solar panels, protecting the cells from environmental factors and improving the durability and efficiency of the panels. This application is particularly important as the demand for renewable energy sources continues to rise. In the paints and coatings industry, PVB is valued for its excellent adhesion, flexibility, and clarity, making it suitable for a variety of applications, including protective and decorative coatings. In the production of glues and adhesives, PVB's strong adhesive properties are leveraged to create products that require reliable bonding strength. In the ink industry, PVB is used to improve the adhesion and durability of inks, particularly in applications where flexibility and resistance to environmental factors are important. Beyond these primary applications, PVB is also used in other areas such as packaging, electronics, and textiles, where its unique properties can be utilized to enhance product performance. The versatility and adaptability of PVB make it a valuable material across a wide range of industries, driving its demand and market growth.

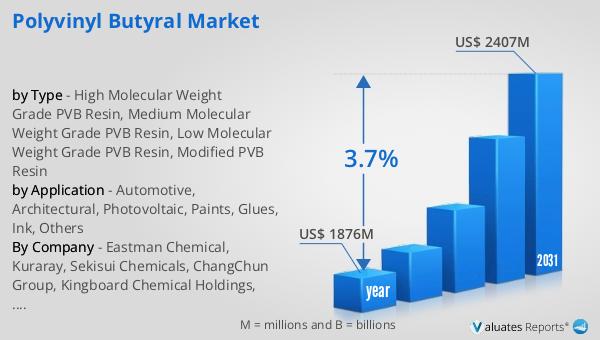

Global Polyvinyl Butyral Market Outlook:

The global market for Polyvinyl Butyral was valued at $1,876 million in 2024 and is anticipated to expand to a revised size of $2,407 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.7% during the forecast period. As of 2023, the top five companies in the market collectively account for approximately 82.06% of the global revenue share, indicating a highly consolidated market structure. The Asia-Pacific region emerges as the largest consumer, representing about 49.00% of global consumption in 2023. This significant consumption is driven by the region's robust automotive and construction industries, which are major end-users of PVB. The market's growth is supported by increasing urbanization, industrialization, and the rising demand for safety and energy-efficient materials. The dominance of a few key players suggests a competitive landscape where innovation and strategic partnerships are crucial for maintaining market position. The market's expansion is further fueled by advancements in technology and the development of new applications for PVB, which continue to enhance its appeal across various industries. As the demand for high-performance materials grows, the global PVB market is poised for sustained growth, driven by its diverse applications and the increasing emphasis on safety and sustainability.

| Report Metric | Details |

| Report Name | Polyvinyl Butyral Market |

| Accounted market size in year | US$ 1876 million |

| Forecasted market size in 2031 | US$ 2407 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Eastman Chemical, Kuraray, Sekisui Chemicals, ChangChun Group, Kingboard Chemical Holdings, Huakai Plastic, Zhejiang Decent Plastic, Wanwei Group, Sichuan EM Technology, Xinfu Pharm, Qingdao Haocheng, Longcheng High-tech Material, Guangda Bingfeng |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |