What is Global Spherical Silica Fillers Market?

The Global Spherical Silica Fillers Market is a specialized segment within the broader materials industry, focusing on the production and distribution of spherical silica particles. These fillers are primarily used to enhance the properties of various materials, such as plastics, rubbers, and coatings, by improving their mechanical strength, thermal stability, and electrical insulation. Spherical silica fillers are favored for their uniform shape and size, which contribute to better flowability and packing density in composite materials. This market is driven by the increasing demand for high-performance materials in industries such as electronics, automotive, and construction. As technology advances, the need for materials that can withstand higher temperatures and provide better insulation becomes more critical, further propelling the growth of this market. The global market for spherical silica fillers is characterized by a competitive landscape with several key players striving to innovate and expand their product offerings to meet the evolving needs of various end-use industries. The market's growth is also supported by ongoing research and development efforts aimed at improving the quality and performance of spherical silica fillers, making them more efficient and cost-effective for manufacturers.

0.01 μm -10 μm, 10 μm -20 μm, Above 20 μm in the Global Spherical Silica Fillers Market:

In the Global Spherical Silica Fillers Market, particle size plays a crucial role in determining the application and performance of the fillers. The size range of 0.01 μm to 10 μm is particularly significant for applications requiring high precision and fine detail. These ultra-fine particles are often used in electronics and semiconductor industries, where they contribute to the miniaturization of components and enhance the performance of electronic devices. Their small size allows for a high degree of dispersion within a matrix, leading to improved mechanical properties and thermal conductivity. On the other hand, the 10 μm to 20 μm size range is commonly used in applications where a balance between performance and cost is essential. These particles are often employed in the production of coatings, adhesives, and sealants, where they provide enhanced durability and resistance to environmental factors. The larger size range, above 20 μm, is typically used in applications that require bulk filling and reinforcement, such as in the construction and automotive industries. These larger particles contribute to the structural integrity and strength of composite materials, making them ideal for use in heavy-duty applications. The choice of particle size is influenced by factors such as the desired properties of the end product, the processing techniques used, and the specific requirements of the application. Manufacturers in the Global Spherical Silica Fillers Market must carefully consider these factors when selecting the appropriate particle size for their products. The ability to tailor the particle size to meet specific application needs is a key competitive advantage in this market, as it allows manufacturers to offer customized solutions to their customers. As the demand for high-performance materials continues to grow, the importance of particle size in the Global Spherical Silica Fillers Market is expected to increase, driving further innovation and development in this field.

EMC, CCL, MUF, Other in the Global Spherical Silica Fillers Market:

The Global Spherical Silica Fillers Market finds extensive usage in various applications, including EMC (Epoxy Molding Compounds), CCL (Copper Clad Laminate), MUF (Melamine Urea Formaldehyde), and other areas. In the field of EMC, spherical silica fillers are used to enhance the thermal and mechanical properties of epoxy molding compounds, which are essential for encapsulating and protecting electronic components. The uniform shape and size of these fillers contribute to better flowability and packing density, resulting in improved thermal conductivity and reduced thermal expansion. This makes them ideal for use in high-performance electronic devices that require reliable protection against heat and mechanical stress. In the CCL industry, spherical silica fillers are used to improve the dimensional stability and electrical insulation properties of copper clad laminates. These laminates are critical components in the manufacturing of printed circuit boards, which are used in a wide range of electronic devices. The addition of spherical silica fillers helps to enhance the performance and reliability of these laminates, making them suitable for use in demanding applications. In the MUF industry, spherical silica fillers are used to improve the mechanical strength and thermal stability of melamine urea formaldehyde resins. These resins are commonly used in the production of laminates, adhesives, and coatings, where they provide enhanced durability and resistance to environmental factors. The use of spherical silica fillers in these applications helps to improve the overall performance and longevity of the end products. In addition to these specific applications, spherical silica fillers are also used in a variety of other industries, including automotive, construction, and coatings. In the automotive industry, they are used to enhance the mechanical properties and thermal stability of composite materials, making them suitable for use in high-performance vehicles. In the construction industry, they are used to improve the strength and durability of building materials, such as concrete and asphalt. In the coatings industry, they are used to enhance the performance and appearance of paints and coatings, providing improved resistance to wear and environmental factors. The versatility and performance-enhancing properties of spherical silica fillers make them a valuable component in a wide range of applications, driving their demand in the Global Spherical Silica Fillers Market.

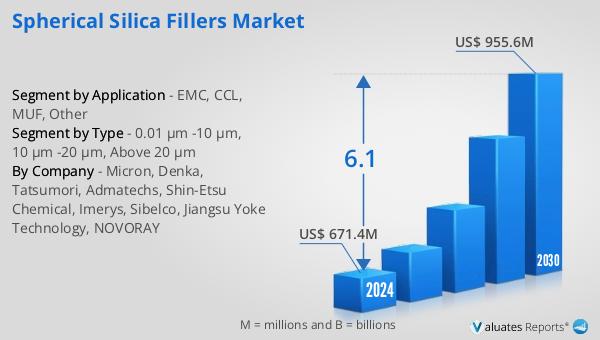

Global Spherical Silica Fillers Market Outlook:

The outlook for the Global Spherical Silica Fillers Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 708 million, and it is anticipated to expand to a revised size of US$ 1063 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.1% over the forecast period. This growth is driven by the increasing demand for high-performance materials across various industries. Notably, the top three players in the market hold a significant share, accounting for 57% of the market. This concentration highlights the competitive nature of the market, with key players striving to innovate and expand their product offerings. In terms of product type, the 10 μm to 20 μm size range is particularly dominant, representing 58% of the market share. This size range is favored for its balance between performance and cost, making it suitable for a wide range of applications. In the application field, the revenue share of EMC (Epoxy Molding Compounds) is substantial, reaching 51%. This underscores the importance of spherical silica fillers in enhancing the thermal and mechanical properties of epoxy molding compounds, which are critical for protecting electronic components. As industries continue to demand materials that offer superior performance and reliability, the Global Spherical Silica Fillers Market is poised for continued growth and development.

| Report Metric | Details |

| Report Name | Spherical Silica Fillers Market |

| Accounted market size in year | US$ 708 million |

| Forecasted market size in 2031 | US$ 1063 million |

| CAGR | 6.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Micron, Denka, Tatsumori, Admatechs, Shin-Etsu Chemical, Imerys, Sibelco, Jiangsu Yoke Technology, NOVORAY |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |