What is Global Bin Picking Robot Market?

The Global Bin Picking Robot Market is an innovative segment within the robotics industry, focusing on the development and deployment of robots capable of identifying, selecting, and picking items from a bin or container. These robots are equipped with advanced vision systems and algorithms that enable them to recognize and handle various objects, regardless of their orientation or position within the bin. This technology is particularly beneficial in industries where automation of repetitive tasks can lead to increased efficiency and reduced labor costs. The market for bin picking robots is driven by the growing demand for automation in manufacturing and logistics, where these robots can significantly enhance productivity by performing tasks that are traditionally labor-intensive. As industries continue to seek ways to optimize operations and reduce human error, the adoption of bin picking robots is expected to rise. These robots are not only capable of handling a wide range of products but also offer flexibility in adapting to different operational environments, making them a valuable asset in modern industrial settings. The integration of artificial intelligence and machine learning further enhances their capabilities, allowing for continuous improvement in performance and adaptability to new tasks.

Suitable for Small Part Sizes, Suitable for Medium Part Sizes, Suitable for Large Part Sizes in the Global Bin Picking Robot Market:

In the Global Bin Picking Robot Market, the suitability of robots for different part sizes is a critical consideration. Robots suitable for small part sizes are designed to handle delicate and intricate items, often found in industries such as electronics and precision engineering. These robots are equipped with high-resolution cameras and sensitive grippers that can accurately identify and manipulate small components without causing damage. Their precision and dexterity make them ideal for tasks such as assembling small electronic devices or sorting tiny mechanical parts. On the other hand, robots suitable for medium part sizes are versatile and can handle a broader range of items. These robots are commonly used in industries like automotive and machinery, where they can efficiently pick and place parts such as gears, bearings, and other medium-sized components. Their ability to adapt to different shapes and weights makes them a valuable tool in assembly lines and manufacturing processes. For large part sizes, bin picking robots are designed with robust grippers and advanced vision systems capable of handling heavy and bulky items. These robots are often employed in industries such as metalworking and construction, where they can manage large metal sheets, pipes, and other substantial components. The ability to automate the handling of large parts not only improves efficiency but also enhances safety by reducing the need for manual lifting and manipulation. Each category of bin picking robots, whether for small, medium, or large parts, plays a crucial role in optimizing industrial operations. By selecting the appropriate robot for the specific part size, businesses can achieve greater precision, speed, and reliability in their processes. The continuous advancements in robotics technology, including improvements in sensors, grippers, and artificial intelligence, further expand the capabilities of these robots, allowing them to tackle increasingly complex tasks. As industries continue to evolve and demand more efficient and flexible automation solutions, the Global Bin Picking Robot Market is poised to grow, offering innovative tools that cater to a wide range of operational needs.

Automotive, Electrical and Electronics, Metal and Machinery, Food, Beverages and Pharmaceuticals, Others in the Global Bin Picking Robot Market:

The Global Bin Picking Robot Market finds extensive applications across various industries, each benefiting from the unique capabilities of these robots. In the automotive industry, bin picking robots are used to automate the handling of parts such as nuts, bolts, and other components that are essential in vehicle assembly. By automating these tasks, automotive manufacturers can increase production speed and reduce the risk of errors, leading to higher quality vehicles and lower production costs. In the electrical and electronics sector, these robots are invaluable for assembling and sorting small components like circuit boards and connectors. The precision and accuracy of bin picking robots ensure that delicate electronic parts are handled with care, minimizing the risk of damage and improving overall product quality. In the metal and machinery industry, bin picking robots are employed to manage heavy and bulky items such as metal sheets and machine parts. Their ability to handle large and awkwardly shaped objects enhances operational efficiency and reduces the need for manual labor, which can be both time-consuming and hazardous. The food, beverages, and pharmaceuticals industries also benefit from bin picking robots, particularly in tasks such as sorting and packaging. These robots can handle a variety of products, from small pharmaceutical vials to larger food packages, ensuring that items are accurately sorted and packaged according to specific requirements. The use of robots in these industries not only improves efficiency but also ensures compliance with hygiene and safety standards. Beyond these sectors, bin picking robots are also used in other industries such as logistics and warehousing, where they play a crucial role in automating the sorting and distribution of goods. The versatility and adaptability of bin picking robots make them an essential tool in modern industrial operations, providing solutions that enhance productivity, accuracy, and safety across a wide range of applications.

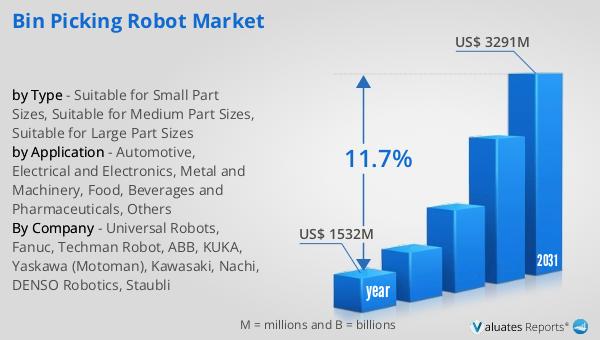

Global Bin Picking Robot Market Outlook:

The global market for bin picking robots was valued at $1,532 million in 2024 and is anticipated to grow significantly, reaching an estimated $3,291 million by 2031. This growth is driven by a compound annual growth rate (CAGR) of 11.7% during the forecast period. Within this market, products designed for small part sizes represent the largest segment, accounting for over 40% of the market share. This dominance is attributed to the increasing demand for precision and efficiency in industries that handle small components, such as electronics and precision engineering. The automotive sector emerges as the largest application segment, holding nearly 35% of the market share. The adoption of bin picking robots in the automotive industry is fueled by the need for automation in handling various parts and components, which enhances production efficiency and reduces costs. As industries continue to embrace automation and seek innovative solutions to improve operational efficiency, the demand for bin picking robots is expected to rise, driving further growth in the market. The continuous advancements in robotics technology, including improvements in sensors, vision systems, and artificial intelligence, are likely to expand the capabilities of bin picking robots, enabling them to tackle increasingly complex tasks and cater to a broader range of applications.

| Report Metric | Details |

| Report Name | Bin Picking Robot Market |

| Accounted market size in year | US$ 1532 million |

| Forecasted market size in 2031 | US$ 3291 million |

| CAGR | 11.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Universal Robots, Fanuc, Techman Robot, ABB, KUKA, Yaskawa (Motoman), Kawasaki, Nachi, DENSO Robotics, Staubli |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |