What is Global Lab Grinding Machines Market?

The Global Lab Grinding Machines Market refers to the industry focused on the production and sale of machines designed to grind and process various materials in laboratory settings. These machines are essential tools in research and development across multiple sectors, including pharmaceuticals, agriculture, food, and chemicals. They are used to reduce the size of particles, ensuring uniformity and consistency in samples, which is crucial for accurate testing and analysis. The market encompasses a range of grinding machines, each tailored to specific applications and material types. As research and development activities continue to expand globally, the demand for efficient and precise lab grinding machines is on the rise. This market is characterized by technological advancements aimed at improving the efficiency, precision, and ease of use of these machines. Manufacturers are continually innovating to meet the evolving needs of laboratories, focusing on features such as automation, digital interfaces, and enhanced safety measures. The market's growth is driven by the increasing emphasis on quality control and the need for reliable data in scientific research. As a result, the Global Lab Grinding Machines Market plays a pivotal role in supporting advancements in various scientific fields.

Ball Mill, Disc Mill, Rotor Mill, Cutting Mill, Others in the Global Lab Grinding Machines Market:

In the realm of the Global Lab Grinding Machines Market, several types of machines stand out due to their specific functionalities and applications. The Ball Mill is a popular choice, known for its ability to grind materials into extremely fine powder. It operates by rotating a cylinder filled with grinding media, such as balls, which crush the material inside. This type of mill is widely used in laboratories for its efficiency in processing both hard and soft materials. The Disc Mill, on the other hand, employs a pair of discs that rotate in opposite directions to grind materials. This machine is particularly effective for grinding brittle materials and is favored for its ability to produce uniform particle sizes. Rotor Mills are designed for rapid size reduction of soft to medium-hard and fibrous materials. They utilize a high-speed rotor to impact and shear the material, making them ideal for applications requiring quick processing times. Cutting Mills are equipped with rotating blades that cut materials into smaller pieces. They are particularly useful for processing tough and fibrous materials, such as plastics and rubber. Lastly, the category of "Others" includes various specialized grinding machines that cater to niche applications. These machines may incorporate unique technologies or designs to address specific laboratory needs. Each type of grinding machine offers distinct advantages, making them indispensable tools in laboratory settings. The choice of machine depends on the material being processed, the desired particle size, and the specific requirements of the research or analysis being conducted. As laboratories continue to demand more precise and efficient grinding solutions, manufacturers are investing in research and development to enhance the capabilities of these machines. This ongoing innovation ensures that the Global Lab Grinding Machines Market remains dynamic and responsive to the needs of scientific research.

Bio & Pharmaceutical, Agriculture & Food, Chemical Material, Others in the Global Lab Grinding Machines Market:

The Global Lab Grinding Machines Market finds extensive application across various sectors, each with unique requirements and challenges. In the Bio & Pharmaceutical industry, these machines are crucial for the preparation of samples for drug development and testing. They enable researchers to achieve the precise particle sizes needed for accurate analysis, ensuring the efficacy and safety of pharmaceutical products. Grinding machines are used to process active pharmaceutical ingredients, excipients, and other materials, facilitating the development of new drugs and therapies. In the Agriculture & Food sector, lab grinding machines play a vital role in quality control and research. They are used to grind food samples for nutritional analysis, ensuring compliance with safety standards and regulations. These machines help in the development of new food products by enabling the precise measurement of ingredients and additives. In the Chemical Material industry, grinding machines are essential for the preparation of samples for chemical analysis and testing. They allow researchers to achieve the uniform particle sizes needed for accurate results, supporting the development of new materials and compounds. The "Others" category includes a wide range of applications, from environmental testing to materials science research. In these fields, lab grinding machines are used to prepare samples for analysis, ensuring the accuracy and reliability of data. The versatility and precision of these machines make them indispensable tools in laboratory settings, supporting advancements in various scientific disciplines. As research and development activities continue to expand, the demand for efficient and reliable lab grinding machines is expected to grow, driving innovation and growth in the Global Lab Grinding Machines Market.

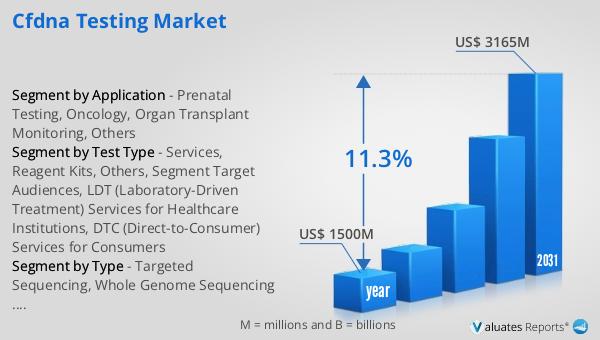

Global Lab Grinding Machines Market Outlook:

The outlook for the Global Lab Grinding Machines Market indicates a promising trajectory. In 2024, the market was valued at approximately US$ 327 million, and it is anticipated to expand to a revised size of US$ 446 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.5% over the forecast period. The market's expansion is driven by the increasing demand for precise and efficient grinding solutions in laboratory settings across various industries. Notably, the top five players in the market accounted for 44% of the total revenue share in 2024, highlighting the competitive landscape and the dominance of key players. These companies are likely to continue investing in research and development to maintain their market positions and meet the evolving needs of their customers. The growth of the Global Lab Grinding Machines Market is also supported by technological advancements aimed at enhancing the performance and capabilities of these machines. As laboratories seek more efficient and reliable grinding solutions, manufacturers are focusing on innovations such as automation, digital interfaces, and improved safety features. This ongoing innovation ensures that the market remains dynamic and responsive to the needs of scientific research. Overall, the Global Lab Grinding Machines Market is poised for significant growth, driven by the increasing emphasis on quality control and the need for reliable data in scientific research.

| Report Metric | Details |

| Report Name | Lab Grinding Machines Market |

| Accounted market size in year | US$ 327 million |

| Forecasted market size in 2031 | US$ 446 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | NETZSCH, RETSCH, Foss Analytical, IKA, NIPPON COKE & ENGINEERING, Buhler, Eriez, Anton Paar (Brabender), PerkinElmer (Perten), SP Industries, Inc., Fitzpatrick, ROOT, HOSOKAWA ALPINE, Cole-Parmer, Fritsch, SIEBTECHNIK GMBH, Ortoalresa, SIEHE, Malvern Panalytical, Kinematica, RUCCA, VIBROTECHNIK |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |