What is Global Industrial Furnace Market?

The global industrial furnace market is a vital segment of the manufacturing industry, playing a crucial role in various industrial processes. Industrial furnaces are devices used to provide heat for a process or can serve as reactors which provide heat of reaction. They are essential in industries such as metallurgy, chemical processing, and materials manufacturing, where high temperatures are required to alter the properties of materials. The market for industrial furnaces is driven by the demand for energy-efficient and environmentally friendly heating solutions. With advancements in technology, modern industrial furnaces are designed to optimize energy consumption and reduce emissions, aligning with global sustainability goals. The market is characterized by a diverse range of furnace types, including electric and combustion-based furnaces, each catering to specific industrial needs. As industries continue to expand and innovate, the demand for advanced industrial furnaces is expected to grow, making this market a key area of focus for manufacturers and investors alike. The global industrial furnace market is poised for significant growth, driven by technological advancements and the increasing need for efficient industrial heating solutions.

Combustion Type, Electric Type in the Global Industrial Furnace Market:

In the global industrial furnace market, two primary types of furnaces are prevalent: combustion type and electric type. Combustion-type furnaces are traditional heating systems that rely on the burning of fuels such as natural gas, oil, or coal to generate heat. These furnaces are widely used in industries where high-temperature processes are essential, such as in metallurgy and chemical processing. The combustion process involves the oxidation of fuel, releasing heat energy that is then transferred to the material being processed. Despite their widespread use, combustion-type furnaces face challenges related to emissions and energy efficiency. As environmental regulations become stricter, industries are seeking ways to reduce the carbon footprint of these furnaces, leading to innovations in burner technology and heat recovery systems. On the other hand, electric-type furnaces represent a more modern approach to industrial heating. These furnaces use electrical energy to generate heat, offering a cleaner and more efficient alternative to combustion-based systems. Electric furnaces are particularly popular in applications where precise temperature control is required, such as in the production of high-quality steel and other alloys. They are also favored in industries where minimizing emissions is a priority, as they do not produce direct combustion byproducts. The adoption of electric furnaces is driven by the increasing availability of renewable energy sources, which can further enhance their environmental benefits. Additionally, advancements in electric furnace technology, such as induction and resistance heating, have expanded their applicability across various industrial sectors. While electric furnaces offer numerous advantages, they also come with challenges, including higher initial costs and the need for a stable and reliable electricity supply. Despite these challenges, the shift towards electric furnaces is gaining momentum, supported by the global push for sustainable industrial practices. In summary, the global industrial furnace market is witnessing a transition from traditional combustion-type furnaces to more efficient and environmentally friendly electric-type systems. This shift is driven by the need to comply with environmental regulations, reduce energy consumption, and improve process efficiency. As industries continue to evolve, the demand for advanced furnace technologies will likely increase, shaping the future of the industrial furnace market.

Metallurgy, Industrial Processing Heating, Heat Treatment, Surface Coating, Others in the Global Industrial Furnace Market:

The global industrial furnace market finds extensive usage across various sectors, each with unique requirements and applications. In the field of metallurgy, industrial furnaces are indispensable for processes such as smelting, refining, and alloying. These high-temperature processes are essential for extracting and purifying metals, making industrial furnaces a critical component of the metallurgical industry. The ability to precisely control temperature and atmosphere within the furnace allows for the production of high-quality metals with specific properties. In industrial processing heating, furnaces are used to provide the necessary heat for chemical reactions and material transformations. This includes applications in the chemical, petrochemical, and pharmaceutical industries, where precise temperature control is crucial for product quality and process efficiency. Industrial furnaces in this sector are designed to handle a wide range of materials and process conditions, making them versatile tools for industrial processing. Heat treatment is another key area where industrial furnaces play a vital role. Heat treatment processes, such as annealing, quenching, and tempering, are used to alter the physical and mechanical properties of materials, particularly metals. Industrial furnaces provide the controlled heating and cooling environments necessary for these processes, ensuring the desired material characteristics are achieved. Surface coating applications also rely heavily on industrial furnaces. In this context, furnaces are used to cure coatings, such as paints and powders, onto various substrates. The controlled heating provided by industrial furnaces ensures uniform coating application and adhesion, resulting in high-quality finished products. This is particularly important in industries such as automotive and aerospace, where surface coatings play a critical role in product performance and durability. Beyond these specific applications, industrial furnaces are used in a variety of other sectors, including glass manufacturing, ceramics, and food processing. In each of these areas, the ability to provide precise and consistent heat is essential for product quality and process efficiency. As industries continue to innovate and expand, the demand for advanced industrial furnace technologies is expected to grow, driving further developments in this dynamic market.

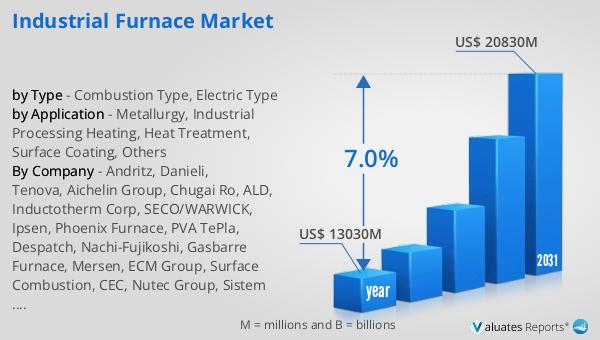

Global Industrial Furnace Market Outlook:

The global industrial furnace market is projected to experience significant growth in the coming years. In 2024, the market was valued at approximately $13,030 million, and it is anticipated to reach a revised size of $20,830 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.0% during the forecast period. This growth is driven by the increasing demand for efficient and environmentally friendly heating solutions across various industries. The market is characterized by a diverse range of manufacturers, with the top five companies holding a combined market share of about 8%. Geographically, Europe is the largest market for industrial furnaces, accounting for approximately 32% of the global market share. This is followed by North America, which holds a share of about 26%. The strong presence of industrial activities and stringent environmental regulations in these regions contribute to their significant market shares. In terms of application, surface coating emerges as the largest segment, representing approximately 41% of the market. The demand for high-quality surface coatings in industries such as automotive, aerospace, and consumer goods drives the growth of this segment. As industries continue to prioritize efficiency and sustainability, the global industrial furnace market is poised for continued expansion, offering numerous opportunities for manufacturers and investors.

| Report Metric | Details |

| Report Name | Industrial Furnace Market |

| Accounted market size in year | US$ 13030 million |

| Forecasted market size in 2031 | US$ 20830 million |

| CAGR | 7.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Andritz, Danieli, Tenova, Aichelin Group, Chugai Ro, ALD, Inductotherm Corp, SECO/WARWICK, Ipsen, Phoenix Furnace, PVA TePla, Despatch, Nachi-Fujikoshi, Gasbarre Furnace, Mersen, ECM Group, Surface Combustion, CEC, Nutec Group, Sistem Teknik, AVS, Wisconsin Oven, TAV Vacuum, Cieffe(Accu) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |