What is Global Automated Liquid Handling Workstation Market?

The Global Automated Liquid Handling Workstation Market is a rapidly evolving sector that plays a crucial role in various scientific and industrial applications. These workstations are designed to automate the process of liquid handling, which is a fundamental task in laboratories. By automating this process, these workstations enhance precision, efficiency, and throughput, reducing the risk of human error and contamination. They are widely used in fields such as genomics, drug discovery, clinical diagnostics, and biotechnology. The market for these workstations is driven by the increasing demand for high-throughput screening, advancements in technology, and the growing need for efficient laboratory workflows. As laboratories strive to improve productivity and accuracy, the adoption of automated liquid handling systems is becoming more prevalent. These systems are equipped with advanced features such as robotic arms, software integration, and customizable protocols, making them versatile tools for a wide range of applications. The market is characterized by continuous innovation, with manufacturers focusing on developing more user-friendly and cost-effective solutions to meet the diverse needs of end-users. As a result, the Global Automated Liquid Handling Workstation Market is poised for significant growth in the coming years, offering numerous opportunities for stakeholders in the industry.

Contact liquid handling workstations, Non-contact automatic liquid handling workstations in the Global Automated Liquid Handling Workstation Market:

Contact liquid handling workstations and non-contact automatic liquid handling workstations are two primary types of systems within the Global Automated Liquid Handling Workstation Market, each offering distinct advantages and applications. Contact liquid handling workstations utilize physical contact between the dispensing tool and the liquid, often employing pipettes or syringes to transfer liquids. This method is highly accurate and is particularly useful for applications requiring precise volume measurements, such as in pharmaceutical research and clinical diagnostics. The contact method ensures that the exact amount of liquid is transferred, which is crucial for experiments where precision is paramount. These systems are often equipped with advanced features like multi-channel pipetting, which allows for simultaneous handling of multiple samples, thereby increasing throughput and efficiency. On the other hand, non-contact automatic liquid handling workstations employ techniques such as acoustic droplet ejection or air displacement to transfer liquids without direct contact. This method minimizes the risk of cross-contamination and is ideal for applications involving sensitive or hazardous materials. Non-contact systems are particularly beneficial in high-throughput screening and genomics, where the rapid and contamination-free transfer of small volumes is essential. These systems are designed to handle a wide range of liquid viscosities and are often integrated with sophisticated software that allows for precise control over dispensing parameters. Both contact and non-contact systems are integral to modern laboratories, offering unique benefits that cater to specific needs. The choice between the two often depends on the nature of the application, the required level of precision, and the type of liquids being handled. As technology continues to advance, these systems are becoming more versatile, with manufacturers developing hybrid models that combine the strengths of both contact and non-contact methods. This innovation is driven by the need for more flexible and efficient solutions that can adapt to the ever-changing demands of scientific research and industrial processes. The Global Automated Liquid Handling Workstation Market is thus characterized by a diverse range of products, each designed to meet the specific requirements of different applications. As laboratories continue to seek ways to enhance productivity and accuracy, the demand for both contact and non-contact liquid handling systems is expected to grow, driving further innovation and development in this dynamic market.

Biopharmaceutical companies, Government Agencies, Medical institutions, Teaching and research institutions, Others in the Global Automated Liquid Handling Workstation Market:

The Global Automated Liquid Handling Workstation Market finds extensive usage across various sectors, including biopharmaceutical companies, government agencies, medical institutions, teaching and research institutions, and others. In biopharmaceutical companies, these workstations are indispensable tools for drug discovery and development. They enable high-throughput screening of compounds, allowing researchers to quickly identify potential drug candidates. The precision and efficiency offered by automated liquid handling systems are crucial in the biopharmaceutical industry, where the rapid and accurate processing of large volumes of samples is essential for successful drug development. Government agencies also utilize these workstations for various applications, including environmental testing, food safety analysis, and forensic investigations. The ability to automate complex liquid handling tasks enhances the reliability and reproducibility of results, which is vital for regulatory compliance and public safety. In medical institutions, automated liquid handling workstations are used for clinical diagnostics and research. They facilitate the processing of patient samples, enabling rapid and accurate diagnostic testing. This is particularly important in the context of personalized medicine, where precise and timely results are critical for effective treatment decisions. Teaching and research institutions benefit from these workstations by streamlining laboratory workflows and enhancing the quality of research. Automated systems allow researchers to focus on data analysis and interpretation, rather than manual pipetting tasks, thereby increasing productivity and innovation. Other sectors, such as agriculture and food and beverage industries, also leverage automated liquid handling systems for various applications, including quality control and product development. The versatility and adaptability of these workstations make them valuable assets across a wide range of industries, driving their adoption and growth in the global market. As the demand for automation and efficiency continues to rise, the Global Automated Liquid Handling Workstation Market is expected to expand further, offering new opportunities for innovation and application in diverse fields.

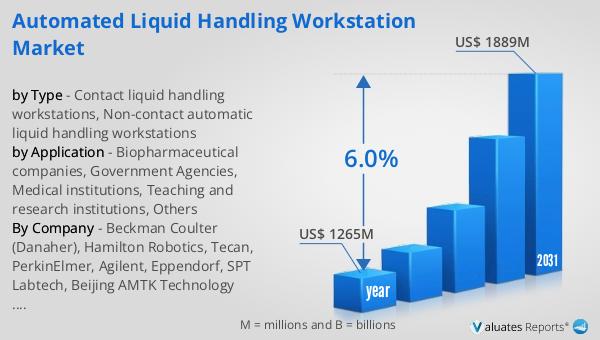

Global Automated Liquid Handling Workstation Market Outlook:

The global market for Automated Liquid Handling Workstations was valued at approximately USD 1,265 million in 2024 and is anticipated to grow to a revised size of USD 1,889 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.0% during the forecast period. This growth trajectory underscores the increasing demand for automation in laboratory processes, driven by the need for enhanced precision, efficiency, and throughput in various scientific and industrial applications. The market is characterized by the presence of several key players, with the top three manufacturers collectively holding a market share of over 35%. This concentration of market power highlights the competitive landscape, where leading companies are continuously innovating to maintain their market position. The growth of the market is fueled by advancements in technology, increasing adoption of automated systems in laboratories, and the expanding application scope of these workstations across different sectors. As laboratories and industries strive to improve productivity and accuracy, the demand for automated liquid handling systems is expected to rise, driving further growth in the market. The focus on developing more user-friendly and cost-effective solutions is also contributing to the market's expansion, as manufacturers aim to cater to the diverse needs of end-users. Overall, the Global Automated Liquid Handling Workstation Market is poised for significant growth, offering numerous opportunities for stakeholders in the industry to capitalize on the increasing demand for automation and efficiency in laboratory processes.

| Report Metric | Details |

| Report Name | Automated Liquid Handling Workstation Market |

| Accounted market size in year | US$ 1265 million |

| Forecasted market size in 2031 | US$ 1889 million |

| CAGR | 6.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Beckman Coulter (Danaher), Hamilton Robotics, Tecan, PerkinElmer, Agilent, Eppendorf, SPT Labtech, Beijing AMTK Technology Development, Analytik Jena (Endress+Hauser), BRAND, MGI Tech, Dispendix, Aurora Biomed, Tomtec, Sansure Biotech, Gilson, Hudson Robotics, TXTB, D.C.Labware, RayKol Group, Ningbo Scientz Biotechnology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |