What is Global Heat Resistant ABS Market?

The Global Heat Resistant ABS Market refers to the worldwide industry focused on the production and distribution of Acrylonitrile Butadiene Styrene (ABS) that can withstand high temperatures. ABS is a popular thermoplastic polymer known for its strength, durability, and resistance to impact. When modified to be heat resistant, ABS can endure higher temperatures without deforming, making it suitable for various applications where thermal stability is crucial. This market is driven by the increasing demand for materials that can maintain their structural integrity under heat stress, particularly in industries such as automotive, electronics, and household appliances. The growth of this market is fueled by technological advancements and the rising need for durable materials in high-performance applications. As industries continue to innovate and expand, the demand for heat-resistant ABS is expected to grow, offering opportunities for manufacturers and suppliers to develop new products and solutions that meet the evolving needs of their customers. The market's expansion is also supported by the increasing focus on sustainability and the development of eco-friendly materials that offer both performance and environmental benefits.

High Heat Resistant, Super High Heat Resistant in the Global Heat Resistant ABS Market:

High Heat Resistant ABS and Super High Heat Resistant ABS are two categories within the Global Heat Resistant ABS Market that cater to different levels of thermal performance requirements. High Heat Resistant ABS is designed to withstand moderately high temperatures, making it suitable for applications where exposure to heat is frequent but not extreme. This type of ABS is often used in automotive parts, such as dashboards and interior components, where it must endure the heat generated by the vehicle's operation and exposure to sunlight. It is also used in household appliances like toasters and hairdryers, where it provides the necessary thermal stability to ensure safety and longevity. The development of High Heat Resistant ABS involves the incorporation of heat stabilizers and other additives that enhance its thermal properties without compromising its mechanical strength or processability. On the other hand, Super High Heat Resistant ABS is engineered to perform under more extreme temperature conditions. This variant is used in applications that require exceptional thermal resistance, such as in high-end consumer electronics and industrial equipment. For instance, in electronics, Super High Heat Resistant ABS is used in components that are subjected to continuous heat, such as in power supply units and heat sinks. In industrial settings, it is used in machinery and equipment that operate at high temperatures, providing the necessary durability and reliability. The development of Super High Heat Resistant ABS involves advanced polymerization techniques and the use of specialized additives that significantly enhance its heat resistance. This makes it an ideal choice for applications where conventional materials would fail due to thermal degradation. The demand for both High Heat Resistant and Super High Heat Resistant ABS is driven by the need for materials that can withstand the increasing thermal demands of modern applications. As industries continue to push the boundaries of performance and efficiency, the importance of materials that can endure high temperatures without losing their structural integrity becomes paramount. Manufacturers in the Global Heat Resistant ABS Market are continually innovating to develop new formulations that offer improved thermal performance, mechanical strength, and environmental sustainability. This ongoing innovation is crucial for meeting the evolving needs of industries and ensuring the continued growth of the market.

Automotive, Household Appliances, High-end Consumer Electronics, Industrial, Others in the Global Heat Resistant ABS Market:

The Global Heat Resistant ABS Market finds extensive usage across various sectors, including automotive, household appliances, high-end consumer electronics, industrial applications, and others. In the automotive industry, heat-resistant ABS is used in the production of various components that require durability and thermal stability. These include interior parts like dashboards, door panels, and consoles, which are exposed to high temperatures due to sunlight and the vehicle's operation. The material's ability to withstand heat without deforming ensures the longevity and safety of these components, making it a preferred choice for automotive manufacturers. In household appliances, heat-resistant ABS is used in products that generate heat during operation, such as toasters, hairdryers, and microwave ovens. Its thermal stability ensures that these appliances can operate safely and efficiently, providing consumers with reliable and durable products. The use of heat-resistant ABS in these applications also enhances the aesthetic appeal of the appliances, as it can be easily molded into various shapes and finishes. In the realm of high-end consumer electronics, heat-resistant ABS is used in the production of components that are subjected to continuous heat, such as power supply units, heat sinks, and casings for electronic devices. Its ability to maintain structural integrity under high temperatures makes it an ideal material for ensuring the performance and reliability of electronic products. In industrial applications, heat-resistant ABS is used in machinery and equipment that operate at high temperatures, providing the necessary durability and reliability. This includes components for manufacturing equipment, industrial ovens, and other high-temperature environments. The material's resistance to thermal degradation ensures that these components can withstand the rigors of industrial use, reducing maintenance costs and downtime. Beyond these primary sectors, heat-resistant ABS is also used in other applications where thermal stability is crucial. This includes the production of medical devices, sports equipment, and construction materials, where the material's strength and heat resistance provide significant advantages. The versatility and performance of heat-resistant ABS make it a valuable material across a wide range of industries, driving its demand and contributing to the growth of the Global Heat Resistant ABS Market.

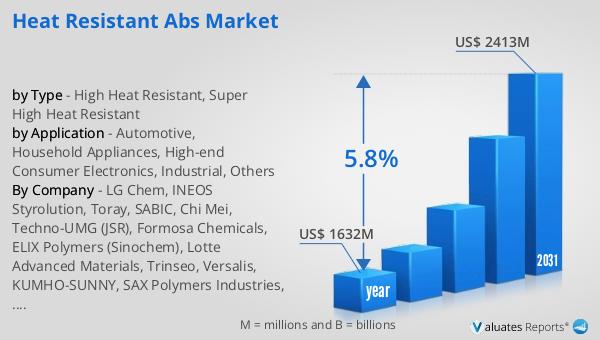

Global Heat Resistant ABS Market Outlook:

In 2024, the global market for Heat Resistant ABS was valued at approximately $1,632 million. By 2031, it is anticipated to expand to a revised size of around $2,413 million, reflecting a compound annual growth rate (CAGR) of 5.8% over the forecast period. The market is dominated by the top five manufacturers, which include LG Chem, INEOS Styrolution, Toray, SABIC, and Chi Mei, collectively holding over 40% of the market share. Among these, LG Chem stands out as the largest manufacturer, with a market share exceeding 10%. South Korea emerges as a pivotal region in the production of heat-resistant ABS, accounting for about 20% of the global market share. In terms of application, the household appliances sector commands a significant portion, with a market share surpassing 30%. This data underscores the robust growth trajectory and competitive landscape of the Heat Resistant ABS Market, highlighting the strategic importance of key players and regions in driving market dynamics. The increasing demand for heat-resistant materials across various industries, coupled with technological advancements, is expected to sustain the market's growth momentum in the coming years.

| Report Metric | Details |

| Report Name | Heat Resistant ABS Market |

| Accounted market size in year | US$ 1632 million |

| Forecasted market size in 2031 | US$ 2413 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | LG Chem, INEOS Styrolution, Toray, SABIC, Chi Mei, Techno-UMG (JSR), Formosa Chemicals, ELIX Polymers (Sinochem), Lotte Advanced Materials, Trinseo, Versalis, KUMHO-SUNNY, SAX Polymers Industries, KKPC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |