What is Global Metallocene Polypropylene Market?

The Global Metallocene Polypropylene Market is a specialized segment within the broader polypropylene industry, characterized by the use of metallocene catalysts in the polymerization process. Metallocene polypropylene is known for its superior properties, such as enhanced clarity, improved impact resistance, and better processability compared to conventional polypropylene. These attributes make it highly desirable in various applications, including packaging, automotive, and consumer goods. The market is driven by the increasing demand for high-performance materials that can meet the stringent requirements of modern applications. Additionally, the growing emphasis on sustainability and recyclability in materials is pushing manufacturers to adopt metallocene polypropylene, which offers better performance with potentially lower environmental impact. The market is also influenced by technological advancements and innovations in catalyst design, which are expected to further enhance the properties and applications of metallocene polypropylene. As industries continue to seek materials that offer a balance between performance and environmental responsibility, the Global Metallocene Polypropylene Market is poised for growth, driven by its unique advantages and the expanding range of applications.

Homopolymerization, Copolymerization in the Global Metallocene Polypropylene Market:

Homopolymerization and copolymerization are two fundamental processes in the production of metallocene polypropylene, each offering distinct properties and applications. Homopolymerization involves the polymerization of a single type of monomer, resulting in a polymer with uniform properties. In the context of metallocene polypropylene, homopolymerization typically produces a material with high stiffness, excellent clarity, and good heat resistance. These properties make it ideal for applications where rigidity and transparency are crucial, such as in packaging films and containers. The uniform structure of homopolymerized metallocene polypropylene also contributes to its superior mechanical properties, making it suitable for demanding applications in the automotive and industrial sectors. On the other hand, copolymerization involves the polymerization of two or more different monomers, resulting in a polymer with a more complex structure and a broader range of properties. In the case of metallocene polypropylene, copolymerization can enhance impact resistance, flexibility, and toughness, making it suitable for applications that require a balance between strength and flexibility. This process allows manufacturers to tailor the properties of metallocene polypropylene to meet specific application requirements, such as in flexible packaging, medical devices, and consumer goods. The ability to customize the properties of metallocene polypropylene through copolymerization is a significant advantage, enabling manufacturers to develop materials that meet the evolving needs of various industries. Furthermore, the use of metallocene catalysts in both homopolymerization and copolymerization processes enhances the control over polymer structure and properties, resulting in materials with consistent quality and performance. This precision in polymerization is particularly important in applications where material consistency and reliability are critical, such as in medical and food packaging. The versatility of metallocene polypropylene, achieved through homopolymerization and copolymerization, is a key factor driving its adoption across diverse industries. As the demand for high-performance materials continues to grow, the ability to produce metallocene polypropylene with tailored properties will be increasingly important in meeting the specific needs of different applications. In summary, homopolymerization and copolymerization are essential processes in the production of metallocene polypropylene, each offering unique advantages and enabling the development of materials with a wide range of properties. The use of metallocene catalysts in these processes enhances the control over polymer structure and properties, resulting in high-performance materials that are well-suited to the demands of modern applications.

Medical Hygiene, Cosmetic Packaging, Food and Beverage Packaging, Others in the Global Metallocene Polypropylene Market:

The Global Metallocene Polypropylene Market finds extensive usage in various sectors, including medical hygiene, cosmetic packaging, food and beverage packaging, and others, due to its superior properties and versatility. In the medical hygiene sector, metallocene polypropylene is valued for its excellent clarity, high strength, and chemical resistance, making it ideal for applications such as medical films, syringes, and other disposable medical devices. Its ability to withstand sterilization processes without compromising on performance is a significant advantage, ensuring safety and reliability in medical applications. In cosmetic packaging, the demand for aesthetically pleasing and durable materials is high, and metallocene polypropylene fits the bill perfectly. Its superior clarity and gloss enhance the visual appeal of cosmetic containers, while its toughness and chemical resistance ensure the integrity and longevity of the packaging. This makes it a preferred choice for high-end cosmetic brands looking to differentiate their products on the shelves. The food and beverage packaging sector is another major area where metallocene polypropylene is extensively used. Its excellent barrier properties, combined with its clarity and strength, make it ideal for packaging applications that require both protection and visibility. Whether it's for packaging fresh produce, snacks, or beverages, metallocene polypropylene ensures that the contents are well-protected from external factors while maintaining their freshness and quality. Additionally, its recyclability aligns with the growing consumer demand for sustainable packaging solutions, making it an attractive option for environmentally conscious brands. Beyond these sectors, metallocene polypropylene is also used in various other applications, such as automotive parts, consumer goods, and industrial components, where its unique combination of properties offers significant advantages. Its ability to be tailored to specific application requirements through processes like copolymerization further enhances its versatility, allowing manufacturers to develop materials that meet the specific needs of different industries. In conclusion, the Global Metallocene Polypropylene Market plays a crucial role in various sectors, offering high-performance materials that meet the stringent requirements of modern applications. Its superior properties, combined with its versatility and sustainability, make it a valuable material in the medical hygiene, cosmetic packaging, food and beverage packaging, and other industries. As the demand for high-performance and sustainable materials continues to grow, the role of metallocene polypropylene in these sectors is expected to expand, driven by its unique advantages and the increasing range of applications.

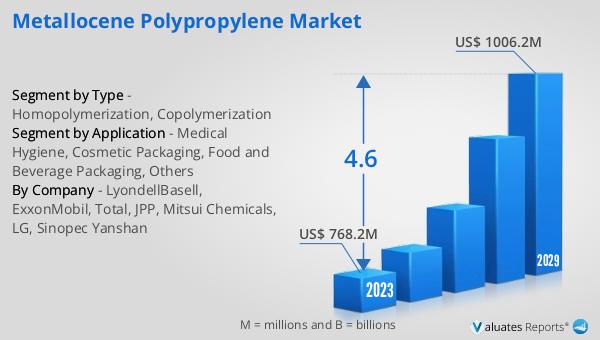

Global Metallocene Polypropylene Market Outlook:

In 2024, the global market for Metallocene Polypropylene was valued at approximately $752 million, and it is anticipated to grow to a revised size of around $1,006 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.3% over the forecast period. The market is dominated by the top five players, who collectively hold a significant share of over 65%. The Asia-Pacific region emerges as the largest market, accounting for about 55% of the total market share, followed by Europe and North America, which hold shares of 22% and 20%, respectively. In terms of application, the food and beverage packaging sector is a major contributor, representing approximately 45% of the market share. This growth trajectory underscores the increasing demand for high-performance materials like metallocene polypropylene, driven by its superior properties and versatility across various applications. The dominance of the Asia-Pacific region highlights the rapid industrialization and growing consumer markets in countries like China and India, where the demand for advanced packaging solutions is on the rise. Meanwhile, the significant share held by the top players indicates a competitive landscape where innovation and technological advancements are key to maintaining market leadership. As industries continue to seek materials that offer a balance between performance and sustainability, the Global Metallocene Polypropylene Market is poised for continued growth, supported by its unique advantages and expanding range of applications.

| Report Metric | Details |

| Report Name | Metallocene Polypropylene Market |

| Accounted market size in year | US$ 752 million |

| Forecasted market size in 2031 | US$ 1006 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | LyondellBasell, ExxonMobil, Total, JPP, Mitsui Chemicals, LG, Sinopec Yanshan |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |