What is Global Aluminum Alloy Automotive Anti-explosion Valve Market?

The Global Aluminum Alloy Automotive Anti-explosion Valve Market is a specialized segment within the automotive industry that focuses on the development and distribution of valves designed to prevent explosions in vehicles. These valves are crucial for enhancing the safety of automobiles by mitigating the risks associated with fuel system explosions, which can occur due to various factors such as accidents or system malfunctions. Made from aluminum alloy, these valves are lightweight yet durable, offering a balance between performance and safety. The market for these valves is driven by the increasing demand for safer vehicles, stringent safety regulations, and the growing automotive industry worldwide. As more consumers and manufacturers prioritize safety, the adoption of anti-explosion valves is expected to rise. These valves are not only essential for passenger vehicles but also for commercial vehicles, where safety is paramount. The market is characterized by continuous innovation, with manufacturers investing in research and development to enhance the efficiency and reliability of these valves. Overall, the Global Aluminum Alloy Automotive Anti-explosion Valve Market plays a vital role in advancing automotive safety standards and is poised for significant growth in the coming years.

(M5、M6、M8), (M12、M20、M24), Others in the Global Aluminum Alloy Automotive Anti-explosion Valve Market:

In the Global Aluminum Alloy Automotive Anti-explosion Valve Market, various types of valves are categorized based on their size and application, including M5, M6, M8, M12, M20, M24, and others. Each of these categories serves specific functions and is designed to meet the diverse needs of different vehicle types and safety requirements. The M5, M6, and M8 valves are typically used in smaller vehicles or applications where space is limited. These valves are compact yet effective, providing essential safety features without compromising the design or performance of the vehicle. They are often used in passenger cars, where the emphasis is on maintaining a balance between safety and aesthetics. The M12, M20, and M24 valves, on the other hand, are larger and are generally used in commercial vehicles or applications that require more robust safety measures. These valves are designed to handle higher pressures and provide enhanced protection against explosions, making them ideal for trucks, buses, and other heavy-duty vehicles. The "Others" category includes valves that do not fit into the standard size classifications but are customized for specific applications or vehicles. These valves are often used in specialized vehicles or in situations where standard valves may not provide the necessary level of safety. The diversity in valve sizes and applications reflects the complexity and variability of the automotive industry, where different vehicles have unique safety requirements. Manufacturers in this market are continually innovating to develop valves that meet the evolving needs of the industry, ensuring that all vehicles, regardless of size or type, are equipped with the best possible safety features. This focus on innovation and customization is a key driver of growth in the Global Aluminum Alloy Automotive Anti-explosion Valve Market, as manufacturers strive to meet the increasing demand for safer vehicles. The market is also influenced by regulatory standards, which vary by region and can impact the types of valves that are required or preferred in different markets. As safety regulations become more stringent, the demand for high-quality, reliable anti-explosion valves is expected to increase, further driving growth in this market. Overall, the Global Aluminum Alloy Automotive Anti-explosion Valve Market is characterized by a wide range of products designed to meet the diverse needs of the automotive industry, with a focus on enhancing safety and performance.

Passenger Cars, Commercial Cars in the Global Aluminum Alloy Automotive Anti-explosion Valve Market:

The usage of Global Aluminum Alloy Automotive Anti-explosion Valves in passenger cars and commercial vehicles is crucial for ensuring safety and compliance with regulatory standards. In passenger cars, these valves are primarily used to enhance the safety of the vehicle's fuel system. They are designed to prevent explosions that can occur due to accidents or system malfunctions, providing peace of mind to drivers and passengers. The lightweight nature of aluminum alloy makes these valves an ideal choice for passenger cars, as they do not add significant weight to the vehicle, which can impact fuel efficiency and performance. In addition to safety, these valves also contribute to the overall reliability and longevity of the vehicle, as they help prevent damage to the fuel system that can result from explosions. In commercial vehicles, the use of aluminum alloy automotive anti-explosion valves is even more critical. Commercial vehicles, such as trucks and buses, often operate under more demanding conditions and are subject to higher safety standards. These vehicles typically carry more passengers or cargo, making safety a top priority. The larger size and capacity of commercial vehicles require more robust safety measures, and the use of anti-explosion valves is an essential part of this. These valves help protect the vehicle's fuel system from explosions, reducing the risk of accidents and ensuring the safety of passengers and cargo. The use of aluminum alloy in these valves provides the necessary strength and durability to withstand the rigors of commercial vehicle operation, while also being lightweight enough to not adversely affect the vehicle's performance. The adoption of anti-explosion valves in both passenger and commercial vehicles is driven by a combination of consumer demand for safer vehicles and regulatory requirements. As safety standards continue to evolve, the importance of these valves in ensuring vehicle safety is likely to increase. Manufacturers are continually working to improve the design and functionality of these valves, ensuring that they meet the highest safety standards and provide reliable protection against explosions. Overall, the use of Global Aluminum Alloy Automotive Anti-explosion Valves in passenger and commercial vehicles is a critical component of modern automotive safety, providing essential protection for drivers, passengers, and cargo.

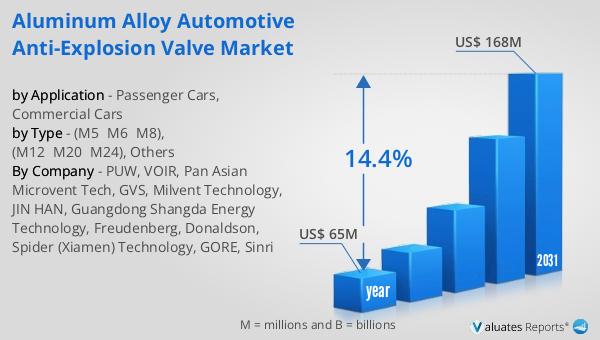

Global Aluminum Alloy Automotive Anti-explosion Valve Market Outlook:

The global market for Aluminum Alloy Automotive Anti-explosion Valves was valued at $65 million in 2024 and is anticipated to expand to a revised size of $168 million by 2031, reflecting a compound annual growth rate (CAGR) of 14.4% over the forecast period. This significant growth is indicative of the increasing demand for enhanced safety features in vehicles, driven by both consumer preferences and regulatory mandates. As the automotive industry continues to evolve, there is a growing emphasis on safety and reliability, which is fueling the demand for advanced safety components such as anti-explosion valves. The projected growth of this market underscores the importance of these valves in modern vehicles, as manufacturers and consumers alike prioritize safety. The robust CAGR of 14.4% highlights the rapid pace at which this market is expanding, driven by technological advancements and the increasing adoption of safety regulations worldwide. As more regions implement stringent safety standards, the demand for high-quality anti-explosion valves is expected to rise, further propelling market growth. This market outlook reflects the dynamic nature of the automotive industry and the critical role that safety components play in shaping its future.

| Report Metric | Details |

| Report Name | Aluminum Alloy Automotive Anti-explosion Valve Market |

| Accounted market size in year | US$ 65 million |

| Forecasted market size in 2031 | US$ 168 million |

| CAGR | 14.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PUW, VOIR, Pan Asian Microvent Tech, GVS, Milvent Technology, JIN HAN, Guangdong Shangda Energy Technology, Freudenberg, Donaldson, Spider (Xiamen) Technology, GORE, Sinri |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |