What is Global Inherited Orphan Blood Disorders Therapeutics Market?

The Global Inherited Orphan Blood Disorders Therapeutics Market is a specialized segment within the broader healthcare industry, focusing on the development and distribution of treatments for rare, inherited blood disorders. These disorders, often referred to as "orphan" diseases due to their rarity, include a variety of genetic conditions that affect the blood's ability to function properly. The market is driven by the need for innovative therapies that can address the unique challenges posed by these conditions, which often have limited treatment options. Companies operating in this market invest heavily in research and development to create effective therapeutics that can improve the quality of life for patients. The market's growth is fueled by advancements in genetic research, increased awareness of rare blood disorders, and supportive regulatory frameworks that encourage the development of orphan drugs. As a result, the Global Inherited Orphan Blood Disorders Therapeutics Market plays a crucial role in providing hope and solutions for individuals affected by these challenging conditions.

Hereditary Hemolytic Diseases, Coagulation Disorders, Metabolic Blood Diseases in the Global Inherited Orphan Blood Disorders Therapeutics Market:

Hereditary Hemolytic Diseases, Coagulation Disorders, and Metabolic Blood Diseases are key categories within the Global Inherited Orphan Blood Disorders Therapeutics Market. Hereditary Hemolytic Diseases are a group of disorders characterized by the premature destruction of red blood cells, leading to anemia and other complications. Conditions such as sickle cell anemia and thalassemia fall under this category. These diseases often require lifelong management, including blood transfusions and medications that help reduce the rate of red blood cell destruction. The development of gene therapies and other innovative treatments is a significant focus within this segment, aiming to provide more effective and less burdensome options for patients. Coagulation Disorders, on the other hand, involve problems with the blood's ability to clot properly. Hemophilia is one of the most well-known coagulation disorders, where patients experience prolonged bleeding due to the lack of specific clotting factors. Treatments for coagulation disorders often involve replacement therapies, where the missing clotting factors are administered to the patient. Recent advancements in gene therapy have also shown promise in providing long-term solutions for these conditions. Metabolic Blood Diseases encompass a range of disorders that affect the body's ability to produce or process certain substances necessary for blood function. These can include conditions like Gaucher's disease, where the body lacks an enzyme needed to break down fatty substances. Treatments for metabolic blood diseases often involve enzyme replacement therapies or other medications that help manage symptoms and prevent complications. The Global Inherited Orphan Blood Disorders Therapeutics Market is actively engaged in developing new therapies for these diseases, with a focus on improving patient outcomes and quality of life. The market's growth is supported by ongoing research and development efforts, as well as collaborations between pharmaceutical companies, research institutions, and patient advocacy groups. These partnerships are crucial in advancing our understanding of these complex disorders and bringing new treatments to market. Overall, the Global Inherited Orphan Blood Disorders Therapeutics Market is a dynamic and rapidly evolving field, driven by the urgent need for effective treatments for rare and challenging blood disorders.

Hospital, Retail Pharmacy, Other in the Global Inherited Orphan Blood Disorders Therapeutics Market:

The usage of therapeutics from the Global Inherited Orphan Blood Disorders Therapeutics Market spans various healthcare settings, including hospitals, retail pharmacies, and other specialized care facilities. In hospitals, these therapeutics play a critical role in the management and treatment of patients with inherited blood disorders. Hospitals often serve as the primary point of care for individuals with severe or complex conditions, providing access to specialized treatments and multidisciplinary care teams. In this setting, therapeutics are used to manage acute episodes, such as severe anemia or bleeding events, and to provide ongoing treatment for chronic conditions. Hospitals also play a key role in administering advanced therapies, such as gene therapy or enzyme replacement therapy, which require specialized expertise and facilities. Retail pharmacies, on the other hand, provide a more accessible option for patients who require ongoing medication management. These pharmacies dispense oral medications, injectables, and other treatments that can be administered at home, allowing patients to manage their condition more independently. Retail pharmacies also offer counseling and support services to help patients adhere to their treatment regimen and manage any side effects. Other specialized care facilities, such as infusion centers or genetic counseling clinics, also play a role in the delivery of therapeutics for inherited blood disorders. Infusion centers provide a convenient and cost-effective option for patients who require regular infusions of medications, such as clotting factors or enzyme replacement therapies. Genetic counseling clinics offer valuable support for patients and families, helping them understand the genetic basis of their condition and explore treatment options. Overall, the Global Inherited Orphan Blood Disorders Therapeutics Market provides a range of treatment options that can be tailored to the unique needs of each patient, ensuring that they receive the best possible care in the most appropriate setting.

Global Inherited Orphan Blood Disorders Therapeutics Market Outlook:

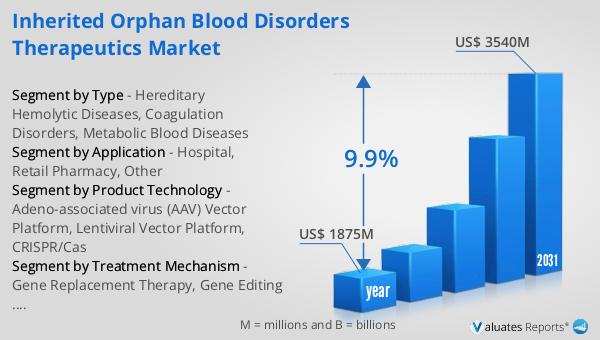

The global market for Inherited Orphan Blood Disorders Therapeutics was valued at $1,875 million in 2024 and is expected to grow significantly, reaching an estimated $3,540 million by 2031. This growth represents a compound annual growth rate (CAGR) of 9.9% over the forecast period. The market's expansion is driven by several factors, including advancements in genetic research, increased awareness of rare blood disorders, and supportive regulatory frameworks that encourage the development of orphan drugs. Companies operating in this market are investing heavily in research and development to create innovative therapies that can address the unique challenges posed by these conditions. The market's growth is also supported by collaborations between pharmaceutical companies, research institutions, and patient advocacy groups, which are crucial in advancing our understanding of these complex disorders and bringing new treatments to market. As a result, the Global Inherited Orphan Blood Disorders Therapeutics Market is poised for significant growth, providing hope and solutions for individuals affected by these challenging conditions.

| Report Metric | Details |

| Report Name | Inherited Orphan Blood Disorders Therapeutics Market |

| Accounted market size in year | US$ 1875 million |

| Forecasted market size in 2031 | US$ 3540 million |

| CAGR | 9.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Treatment Mechanism |

|

| Segment by Product Technology |

|

| Segment by Application |

|

| By Region |

|

| By Company | Biogen, Novartis, Gilead Sciences, Sarepta Therapeutics, Alnylam Pharmaceuticals, Amgen, Spark Therapeutics, Akcea Therapeutics, Sunway Biotech, SIBIONO, AnGes, Orchard Therapeutics, Human Stem Cells Institute |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |