What is Global Cosmetic Grade Collagen Market?

The Global Cosmetic Grade Collagen Market is a specialized segment within the broader collagen industry, focusing on the production and distribution of collagen specifically formulated for cosmetic applications. Collagen, a protein naturally found in the skin, bones, and connective tissues, plays a crucial role in maintaining skin elasticity and firmness. In the cosmetic industry, collagen is highly valued for its ability to enhance skin texture, reduce the appearance of wrinkles, and promote a youthful appearance. The demand for cosmetic grade collagen has been on the rise due to increasing consumer awareness about skincare and the growing popularity of anti-aging products. This market encompasses various types of collagen, including fish, bovine, and other sources, each offering unique benefits for skin health. Manufacturers in this market are continually innovating to develop new formulations and delivery methods to meet the evolving needs of consumers. The global reach of this market is expanding, with significant growth observed in regions such as North America, Europe, and Asia-Pacific. As consumers continue to prioritize skincare and beauty, the Global Cosmetic Grade Collagen Market is poised for sustained growth, driven by advancements in technology and increasing consumer demand for effective skincare solutions.

Fish Collagen, Bovine Collagen, Others in the Global Cosmetic Grade Collagen Market:

Fish collagen, bovine collagen, and other types of collagen each play a distinct role in the Global Cosmetic Grade Collagen Market, offering unique benefits and applications. Fish collagen, derived from the skin and scales of fish, is highly regarded for its superior absorption and bioavailability compared to other collagen sources. This type of collagen is rich in Type I collagen, which is the most abundant collagen type in the human body and is essential for maintaining skin elasticity and hydration. Fish collagen is often used in anti-aging and moisturizing cosmetic products due to its ability to penetrate the skin more effectively, promoting a youthful and radiant complexion. Additionally, fish collagen is considered a more sustainable and environmentally friendly option, as it utilizes by-products from the fishing industry, reducing waste and promoting resource efficiency. On the other hand, bovine collagen, sourced from cows, is another popular choice in the cosmetic industry. It primarily contains Type I and Type III collagen, both of which are crucial for skin health. Bovine collagen is known for its ability to improve skin elasticity, reduce wrinkles, and enhance overall skin texture. It is often used in a variety of cosmetic products, including creams, serums, and masks, to provide a firming and rejuvenating effect. Bovine collagen is also favored for its cost-effectiveness and availability, making it a widely used ingredient in the cosmetic industry. In addition to fish and bovine collagen, other sources of collagen, such as porcine and plant-based collagen, are also gaining traction in the market. Porcine collagen, derived from pigs, shares similar properties with bovine collagen and is often used as an alternative for those who may have dietary restrictions or preferences. Plant-based collagen, while not true collagen, is formulated to mimic the effects of animal-derived collagen and is gaining popularity among vegan and environmentally conscious consumers. These alternative sources of collagen are expanding the options available in the market, catering to a diverse range of consumer needs and preferences. Overall, the Global Cosmetic Grade Collagen Market is characterized by a variety of collagen types, each offering unique benefits and applications, contributing to the market's growth and diversification.

Anti-Aging Cosmetic Products, Moisturizing Cosmetic Products, Oil-Free Hydrating Cosmetic Products in the Global Cosmetic Grade Collagen Market:

The usage of Global Cosmetic Grade Collagen Market in anti-aging cosmetic products, moisturizing cosmetic products, and oil-free hydrating cosmetic products is extensive and varied, catering to the diverse needs of consumers seeking effective skincare solutions. In the realm of anti-aging cosmetic products, collagen plays a pivotal role in combating the visible signs of aging, such as wrinkles, fine lines, and sagging skin. Collagen-based formulations are designed to replenish the skin's natural collagen levels, promoting firmness and elasticity. These products often include collagen serums, creams, and masks that work to smooth out wrinkles and restore a youthful appearance. The inclusion of collagen in anti-aging products is driven by its ability to stimulate the skin's natural repair processes, enhancing skin texture and reducing the appearance of age-related imperfections. Moisturizing cosmetic products also benefit significantly from the incorporation of collagen. Collagen's hydrating properties help to lock in moisture, preventing dryness and maintaining the skin's suppleness. Collagen-infused moisturizers and lotions are popular choices for individuals seeking to keep their skin hydrated and plump. These products work by forming a protective barrier on the skin's surface, reducing water loss and ensuring long-lasting hydration. The use of collagen in moisturizing products is particularly beneficial for individuals with dry or sensitive skin, as it provides a gentle yet effective solution for maintaining optimal skin moisture levels. In the category of oil-free hydrating cosmetic products, collagen serves as a key ingredient for those with oily or acne-prone skin. Oil-free formulations are designed to provide hydration without adding excess oil, making them ideal for individuals who struggle with shine and breakouts. Collagen's lightweight and non-greasy nature make it an excellent choice for oil-free products, as it delivers essential moisture without clogging pores or exacerbating oiliness. These products often include oil-free collagen gels, serums, and creams that offer hydration and nourishment without compromising the skin's natural balance. The versatility of collagen in these various cosmetic applications highlights its importance in the skincare industry. As consumers continue to seek effective and targeted skincare solutions, the demand for collagen-based products in anti-aging, moisturizing, and oil-free hydrating categories is expected to remain strong. The Global Cosmetic Grade Collagen Market is well-positioned to meet this demand, offering a wide range of products that cater to different skin types and concerns, ultimately enhancing the overall skincare experience for consumers.

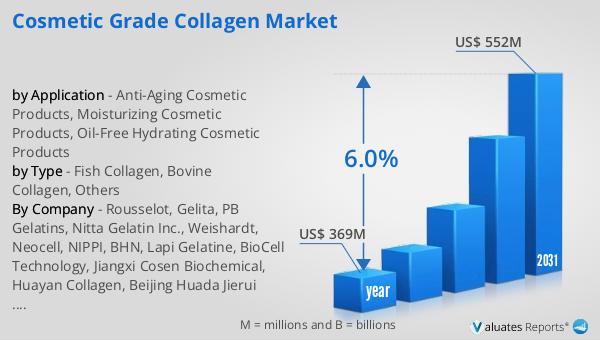

Global Cosmetic Grade Collagen Market Outlook:

The worldwide market for Cosmetic Grade Collagen was estimated to be worth $369 million in 2024. It is anticipated to grow to a new size of $552 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.0% over the forecast period. This growth trajectory underscores the increasing demand for collagen in the cosmetic industry, driven by consumer interest in skincare and anti-aging products. The market's expansion is fueled by advancements in collagen production technologies and the development of innovative formulations that cater to diverse consumer needs. As more individuals become aware of the benefits of collagen for skin health, the market is poised for continued growth. The rising popularity of collagen-infused products, such as creams, serums, and masks, is contributing to the market's upward trend. Additionally, the growing focus on sustainability and environmentally friendly practices is encouraging the use of alternative collagen sources, such as fish and plant-based collagen, further diversifying the market. The Global Cosmetic Grade Collagen Market is set to experience robust growth, driven by the increasing demand for effective skincare solutions and the continuous innovation in collagen-based products.

| Report Metric | Details |

| Report Name | Cosmetic Grade Collagen Market |

| Accounted market size in year | US$ 369 million |

| Forecasted market size in 2031 | US$ 552 million |

| CAGR | 6.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Rousselot, Gelita, PB Gelatins, Nitta Gelatin Inc., Weishardt, Neocell, NIPPI, BHN, Lapi Gelatine, BioCell Technology, Jiangxi Cosen Biochemical, Huayan Collagen, Beijing Huada Jierui Biotechnology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |