What is Global Bonding NdFeB Market?

The Global Bonding NdFeB Market refers to the worldwide industry focused on the production and application of bonded neodymium-iron-boron (NdFeB) magnets. These magnets are known for their exceptional magnetic strength and are used in various applications across different sectors. Bonded NdFeB magnets are created by combining NdFeB powder with a binding agent, which allows them to be molded into complex shapes and sizes. This versatility makes them highly desirable in industries that require precise and efficient magnetic solutions. The market for these magnets is driven by the increasing demand for miniaturized electronic devices, automotive components, and renewable energy technologies. As industries continue to innovate and seek more efficient ways to utilize magnetic materials, the Global Bonding NdFeB Market is expected to grow, offering new opportunities for manufacturers and suppliers. The market's expansion is also influenced by advancements in manufacturing techniques and the development of new applications that leverage the unique properties of bonded NdFeB magnets. Overall, the Global Bonding NdFeB Market plays a crucial role in supporting technological advancements and meeting the growing demand for high-performance magnetic solutions across various industries.

Calendering, Injection Molding, Extrusion in the Global Bonding NdFeB Market:

Calendering, injection molding, and extrusion are three key manufacturing processes used in the Global Bonding NdFeB Market to produce magnets with specific shapes and properties. Calendering involves the process of rolling NdFeB powder mixed with a binding agent into thin sheets. This method is particularly useful for creating flat, flexible magnets that can be easily cut or shaped into desired forms. The calendering process allows for the production of magnets with uniform thickness and consistent magnetic properties, making it ideal for applications that require precise magnetic performance. Injection molding, on the other hand, involves injecting a mixture of NdFeB powder and a binding agent into a mold under high pressure. This process is highly efficient for producing complex shapes and intricate designs, as it allows for the creation of magnets with detailed features and tight tolerances. Injection molding is widely used in the automotive and electronics industries, where precision and reliability are critical. Extrusion is another important process in the Global Bonding NdFeB Market, involving the continuous forcing of a mixture of NdFeB powder and a binding agent through a die to create long, uniform shapes. This method is particularly suitable for producing magnets with consistent cross-sectional profiles, such as rods or tubes. Extrusion allows for the production of magnets with high dimensional accuracy and excellent mechanical properties, making it ideal for applications that require strong and durable magnetic components. Each of these manufacturing processes offers unique advantages and is chosen based on the specific requirements of the application. The choice of process depends on factors such as the desired shape, size, and magnetic properties of the final product, as well as the production volume and cost considerations. As the Global Bonding NdFeB Market continues to evolve, advancements in these manufacturing techniques are expected to enhance the performance and versatility of bonded NdFeB magnets, opening up new possibilities for their use in various industries.

Automotive, Electrical and Electronics, Industrial, Others in the Global Bonding NdFeB Market:

The usage of bonded NdFeB magnets in the Global Bonding NdFeB Market spans across several key industries, including automotive, electrical and electronics, industrial, and others. In the automotive sector, bonded NdFeB magnets are used in various components such as sensors, actuators, and electric motors. Their high magnetic strength and ability to be molded into complex shapes make them ideal for applications that require compact and efficient magnetic solutions. For instance, in electric vehicles, bonded NdFeB magnets are used in the motors that drive the wheels, providing the necessary torque and power for efficient operation. In the electrical and electronics industry, bonded NdFeB magnets are used in a wide range of devices, from small consumer electronics to large industrial equipment. Their ability to provide strong magnetic fields in compact sizes makes them ideal for use in speakers, hard drives, and other electronic components. In industrial applications, bonded NdFeB magnets are used in machinery and equipment that require precise and reliable magnetic performance. They are used in various applications, including magnetic separators, lifting devices, and magnetic bearings. The versatility and high performance of bonded NdFeB magnets make them suitable for a wide range of industrial applications, where they contribute to improved efficiency and productivity. In addition to these key industries, bonded NdFeB magnets are also used in other sectors, such as healthcare and renewable energy. In healthcare, they are used in medical devices and equipment, where their strong magnetic properties are essential for accurate and reliable performance. In renewable energy, bonded NdFeB magnets are used in wind turbines and other energy generation systems, where they help improve efficiency and reduce energy consumption. Overall, the usage of bonded NdFeB magnets in the Global Bonding NdFeB Market is diverse and continues to expand as new applications and technologies emerge.

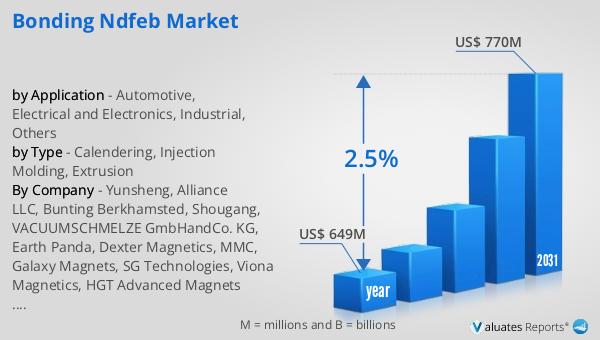

Global Bonding NdFeB Market Outlook:

The global market for Bonding NdFeB was valued at $649 million in 2024 and is anticipated to grow to a revised size of $770 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.5% during the forecast period. This growth is indicative of the increasing demand for high-performance magnetic solutions across various industries. The market's expansion is driven by the rising need for miniaturized electronic devices, advancements in automotive technology, and the growing focus on renewable energy sources. As industries continue to innovate and seek more efficient ways to utilize magnetic materials, the demand for bonded NdFeB magnets is expected to rise. The market's growth is also supported by advancements in manufacturing techniques, which enhance the performance and versatility of these magnets. As a result, manufacturers and suppliers in the Global Bonding NdFeB Market are presented with new opportunities to meet the evolving needs of their customers. The market's outlook remains positive, with continued growth expected as industries increasingly rely on bonded NdFeB magnets for their unique properties and capabilities.

| Report Metric | Details |

| Report Name | Bonding NdFeB Market |

| Accounted market size in year | US$ 649 million |

| Forecasted market size in 2031 | US$ 770 million |

| CAGR | 2.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Yunsheng, Alliance LLC, Bunting Berkhamsted, Shougang, VACUUMSCHMELZE GmbHandCo. KG, Earth Panda, Dexter Magnetics, MMC, Galaxy Magnets, SG Technologies, Viona Magnetics, HGT Advanced Magnets Co.,Ltd, Magnaproducts, Inc., Stanford Magnets |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |