What is Pharmaceutical High Borosilicate Glass - Global Market?

Pharmaceutical high borosilicate glass is a specialized type of glass that is highly valued in the global market for its exceptional properties, making it ideal for pharmaceutical applications. This glass is composed of silica and boron trioxide, which gives it a low coefficient of thermal expansion, making it resistant to thermal shock. This means it can withstand sudden temperature changes without cracking or breaking, a crucial feature for pharmaceutical containers that may be subjected to various temperature conditions during storage and transportation. Additionally, high borosilicate glass is chemically inert, meaning it does not react with the contents it holds, ensuring the purity and stability of pharmaceutical products. This makes it an excellent choice for packaging sensitive medications and vaccines. The global market for pharmaceutical high borosilicate glass is driven by the increasing demand for safe and reliable packaging solutions in the pharmaceutical industry, as well as the growing emphasis on quality and safety standards. As pharmaceutical companies continue to innovate and develop new drugs, the need for high-quality packaging materials like high borosilicate glass is expected to rise, further fueling the market's growth.

Ordinary High Borosilicate Glass, Float High Borosilicate Glass in the Pharmaceutical High Borosilicate Glass - Global Market:

Ordinary high borosilicate glass and float high borosilicate glass are two variations of high borosilicate glass that are used in the pharmaceutical industry, each with distinct characteristics and applications. Ordinary high borosilicate glass is known for its excellent thermal resistance and chemical stability, making it suitable for a wide range of pharmaceutical applications. It is commonly used in the production of laboratory glassware, such as beakers and test tubes, where it can withstand high temperatures and exposure to various chemicals without degrading. This type of glass is also used in the manufacturing of pharmaceutical containers, such as bottles and jars, where its inert nature ensures that the contents remain uncontaminated and stable over time. On the other hand, float high borosilicate glass is produced using a specialized float process that results in a smooth, flat surface. This type of glass is often used in the production of flat glass products, such as windows and panels, but it also has applications in the pharmaceutical industry. Float high borosilicate glass is used in the production of glass vials and ampoules, where its clarity and strength are essential for ensuring the integrity and visibility of the contents. The smooth surface of float high borosilicate glass also makes it easier to clean and sterilize, which is crucial for maintaining the sterility of pharmaceutical products. Both ordinary and float high borosilicate glass play important roles in the pharmaceutical industry, providing reliable and safe packaging solutions that meet the stringent quality and safety standards required for pharmaceutical products. As the demand for high-quality pharmaceutical packaging continues to grow, the market for both ordinary and float high borosilicate glass is expected to expand, driven by the need for innovative and reliable packaging solutions that ensure the safety and efficacy of pharmaceutical products.

Glass Tube, Glass Vial, Others in the Pharmaceutical High Borosilicate Glass - Global Market:

Pharmaceutical high borosilicate glass is widely used in various applications within the pharmaceutical industry, including glass tubes, glass vials, and other specialized containers. Glass tubes made from high borosilicate glass are commonly used in laboratories and research facilities for a variety of purposes, such as conducting experiments and storing samples. The thermal resistance and chemical stability of high borosilicate glass make it an ideal material for glass tubes, as it can withstand high temperatures and exposure to harsh chemicals without degrading. This ensures that the contents of the glass tubes remain uncontaminated and stable, which is crucial for accurate and reliable research results. Glass vials made from high borosilicate glass are another important application in the pharmaceutical industry. These vials are used to store and transport a wide range of pharmaceutical products, including vaccines, injectable drugs, and other sensitive medications. The inert nature of high borosilicate glass ensures that the contents of the vials remain pure and stable, while its thermal resistance protects the contents from temperature fluctuations during storage and transportation. Additionally, the clarity of high borosilicate glass allows for easy inspection of the contents, ensuring that any issues or contaminants can be quickly identified and addressed. Other applications of pharmaceutical high borosilicate glass include the production of ampoules, syringes, and other specialized containers used in the pharmaceutical industry. These containers are designed to meet the stringent quality and safety standards required for pharmaceutical products, ensuring that the contents remain safe and effective throughout their shelf life. The versatility and reliability of high borosilicate glass make it an essential material in the pharmaceutical industry, providing safe and effective packaging solutions for a wide range of applications. As the demand for high-quality pharmaceutical packaging continues to grow, the market for pharmaceutical high borosilicate glass is expected to expand, driven by the need for innovative and reliable packaging solutions that ensure the safety and efficacy of pharmaceutical products.

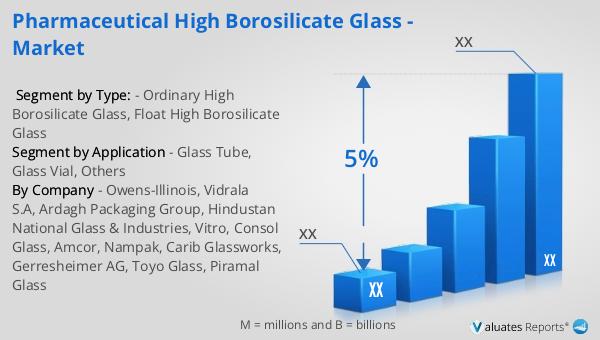

Pharmaceutical High Borosilicate Glass - Global Market Outlook:

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, and it is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years. This growth is indicative of the increasing demand for pharmaceutical products and the continuous advancements in medical research and drug development. In comparison, the chemical drug market has shown a steady increase, rising from 1,005 billion USD in 2018 to an estimated 1,094 billion USD in 2022. This growth in the chemical drug market reflects the ongoing need for effective and innovative chemical-based medications to address a wide range of health conditions. The expansion of both the pharmaceutical and chemical drug markets highlights the importance of reliable and high-quality packaging solutions, such as pharmaceutical high borosilicate glass, to ensure the safety and efficacy of these products. As the pharmaceutical industry continues to evolve and expand, the demand for advanced packaging materials that meet stringent quality and safety standards is expected to rise, further driving the growth of the pharmaceutical high borosilicate glass market.

| Report Metric | Details |

| Report Name | Pharmaceutical High Borosilicate Glass - Market |

| CAGR | 5% |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Owens-Illinois, Vidrala S.A, Ardagh Packaging Group, Hindustan National Glass & Industries, Vitro, Consol Glass, Amcor, Nampak, Carib Glassworks, Gerresheimer AG, Toyo Glass, Piramal Glass |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |