What is Influenza H3N2 Hemagglutinin ELISA Kit - Global Market?

The Influenza H3N2 Hemagglutinin ELISA Kit is a specialized tool used in the global market for detecting and quantifying the presence of the H3N2 strain of the influenza virus. This kit is particularly significant because the H3N2 strain is known for causing seasonal flu outbreaks, which can lead to severe health complications, especially in vulnerable populations such as the elderly and those with compromised immune systems. The ELISA (Enzyme-Linked Immunosorbent Assay) technology employed in these kits allows for precise and efficient detection of the hemagglutinin protein, a key component of the virus that facilitates its entry into host cells. By providing accurate results, these kits play a crucial role in both clinical settings and research laboratories, aiding in the monitoring and management of influenza outbreaks. The global market for these kits is driven by the ongoing need for effective diagnostic tools to combat influenza, as well as the increasing awareness of the importance of early detection and prevention strategies. As healthcare systems worldwide strive to improve their response to infectious diseases, the demand for reliable diagnostic kits like the Influenza H3N2 Hemagglutinin ELISA Kit continues to grow.

Human, Mouse, Rat, Other in the Influenza H3N2 Hemagglutinin ELISA Kit - Global Market:

The Influenza H3N2 Hemagglutinin ELISA Kit is utilized across various species, including humans, mice, rats, and others, each serving distinct purposes in the global market. In humans, the kit is primarily used for diagnostic purposes, helping healthcare professionals identify and confirm cases of H3N2 influenza. This is crucial for timely treatment and management of the disease, reducing the risk of severe complications and preventing the spread of the virus. In research settings, human samples are often analyzed to study the virus's behavior, track mutations, and develop vaccines. Mice are commonly used as model organisms in influenza research due to their genetic similarities to humans and their ability to mimic human immune responses. The ELISA kit is employed to study the immune response to H3N2 infection in mice, providing insights into the virus's pathogenesis and aiding in the development of new therapeutic strategies. Similarly, rats are used in research to understand the virus's impact on different biological systems and to test the efficacy of potential treatments. The use of the ELISA kit in these studies is essential for obtaining accurate and reliable data, which can be translated into human applications. Other species, such as ferrets, are also used in influenza research due to their susceptibility to the virus and their ability to exhibit similar symptoms to humans. The ELISA kit is instrumental in these studies, allowing researchers to monitor the virus's spread and evaluate the effectiveness of vaccines and antiviral drugs. The global market for the Influenza H3N2 Hemagglutinin ELISA Kit is thus driven by its diverse applications across different species, each contributing to a better understanding of the virus and the development of effective prevention and treatment strategies. As the threat of influenza continues to loom, the demand for these kits remains strong, underscoring their importance in both clinical and research settings.

Hospital, Research Institute, Other in the Influenza H3N2 Hemagglutinin ELISA Kit - Global Market:

The Influenza H3N2 Hemagglutinin ELISA Kit finds extensive usage in hospitals, research institutes, and other settings, each playing a vital role in the global market. In hospitals, the kit is primarily used for diagnostic purposes, enabling healthcare professionals to quickly and accurately identify cases of H3N2 influenza. This is crucial for initiating timely treatment and implementing appropriate infection control measures to prevent the spread of the virus within healthcare facilities and the broader community. The ability to rapidly diagnose influenza cases also helps reduce the burden on healthcare systems, allowing for more efficient allocation of resources and improving patient outcomes. In research institutes, the ELISA kit is an invaluable tool for studying the H3N2 virus, its behavior, and its impact on different biological systems. Researchers use the kit to analyze samples from various species, including humans, mice, and rats, to gain insights into the virus's pathogenesis, track mutations, and evaluate the efficacy of vaccines and antiviral drugs. The data obtained from these studies are crucial for developing new therapeutic strategies and improving existing prevention and treatment methods. Other settings where the ELISA kit is used include public health laboratories and pharmaceutical companies. Public health laboratories utilize the kit for surveillance purposes, monitoring the prevalence and spread of the H3N2 virus in different populations. This information is essential for informing public health policies and strategies aimed at controlling influenza outbreaks. Pharmaceutical companies, on the other hand, use the kit in the development and testing of new vaccines and antiviral drugs, ensuring their safety and efficacy before they are brought to market. The global market for the Influenza H3N2 Hemagglutinin ELISA Kit is thus driven by its wide range of applications across different sectors, each contributing to the fight against influenza and the protection of public health. As the threat of influenza continues to pose significant challenges, the demand for these kits remains robust, highlighting their critical role in both clinical and research settings.

Influenza H3N2 Hemagglutinin ELISA Kit - Global Market Outlook:

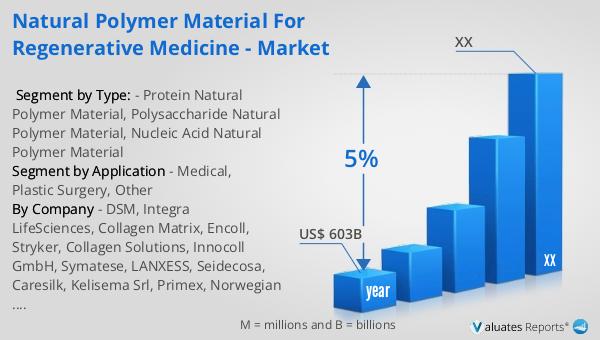

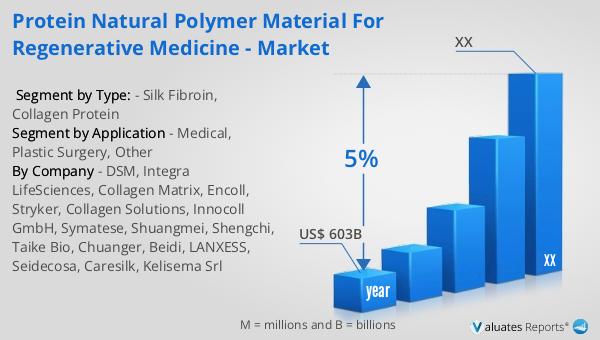

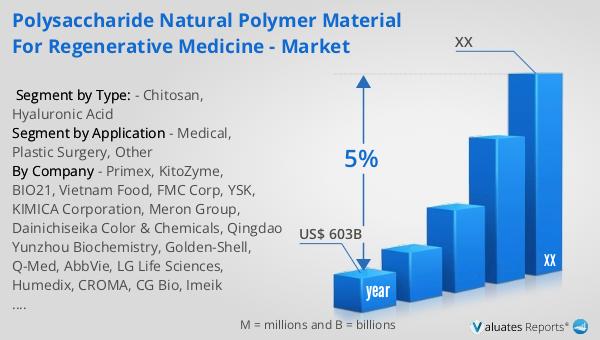

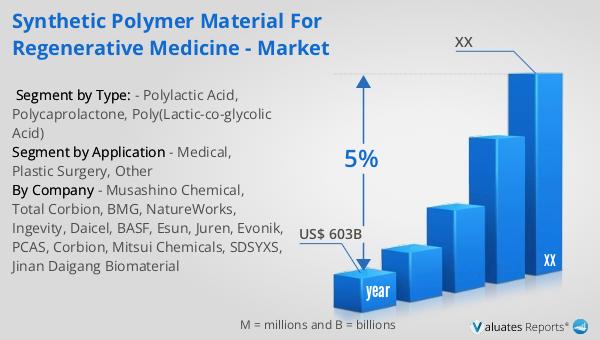

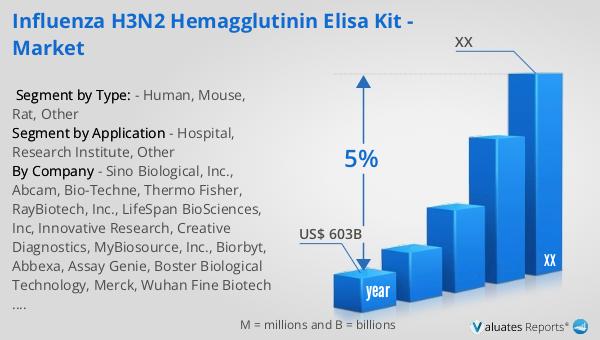

Based on our research, the global market for medical devices, which includes the Influenza H3N2 Hemagglutinin ELISA Kit, is projected to be valued at approximately $603 billion in 2023. This market is anticipated to experience a compound annual growth rate (CAGR) of 5% over the next six years. This growth is driven by several factors, including the increasing prevalence of infectious diseases, the rising demand for advanced diagnostic tools, and the growing awareness of the importance of early detection and prevention strategies. The ELISA kit, in particular, plays a crucial role in the diagnosis and management of influenza, a common and potentially severe infectious disease. As healthcare systems worldwide continue to prioritize the development and implementation of effective diagnostic solutions, the demand for reliable and accurate tools like the Influenza H3N2 Hemagglutinin ELISA Kit is expected to rise. Additionally, advancements in technology and the increasing focus on personalized medicine are likely to further drive the growth of the medical devices market, creating new opportunities for innovation and development. As a result, the global market for medical devices, including the Influenza H3N2 Hemagglutinin ELISA Kit, is poised for significant expansion in the coming years, underscoring the importance of these tools in improving healthcare outcomes and enhancing public health.

| Report Metric | Details |

| Report Name | Influenza H3N2 Hemagglutinin ELISA Kit - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Sino Biological, Inc., Abcam, Bio-Techne, Thermo Fisher, RayBiotech, Inc., LifeSpan BioSciences, Inc, Innovative Research, Creative Diagnostics, MyBiosource, Inc., Biorbyt, Abbexa, Assay Genie, Boster Biological Technology, Merck, Wuhan Fine Biotech Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |