What is Global Robotic Arm (RA) Market?

The Global Robotic Arm (RA) Market refers to the worldwide industry focused on the development, production, and application of robotic arms. These robotic arms are mechanical devices that mimic the functions of a human arm and are used in various industries to perform tasks that require precision, speed, and efficiency. The market encompasses a wide range of robotic arms, from simple two-axis models to complex multi-axis systems. These devices are employed in manufacturing, healthcare, entertainment, and other sectors to automate processes, improve productivity, and reduce human error. The market is driven by advancements in technology, increasing demand for automation, and the need for improved operational efficiency. As industries continue to adopt robotic arms for various applications, the market is expected to grow, offering new opportunities for innovation and development.

6 Axis, 7 Axis, Other in the Global Robotic Arm (RA) Market:

In the Global Robotic Arm (RA) Market, robotic arms are categorized based on the number of axes they possess, which determines their range of motion and flexibility. A 6-axis robotic arm is the most common type, featuring six degrees of freedom that allow it to move in six different directions. This type of arm is highly versatile and can perform complex tasks such as welding, painting, and assembly with high precision. The six axes include three for positioning (X, Y, and Z) and three for orientation (roll, pitch, and yaw), making it suitable for a wide range of industrial applications. On the other hand, a 7-axis robotic arm adds an additional degree of freedom, providing even greater flexibility and maneuverability. This extra axis allows the arm to reach around obstacles and work in confined spaces, making it ideal for tasks that require intricate movements and access to hard-to-reach areas. The 7-axis robotic arm is often used in applications such as medical surgery, where precision and dexterity are crucial. Other types of robotic arms in the market include those with fewer or more than six or seven axes, each designed for specific tasks and industries. For example, a 4-axis robotic arm is commonly used in pick-and-place operations, where speed and accuracy are essential, but the range of motion is less critical. Similarly, an 8-axis or higher robotic arm may be used in specialized applications that require even more complex movements and capabilities. The choice of robotic arm depends on the specific requirements of the task, including the level of precision, speed, and flexibility needed. As technology continues to advance, the development of robotic arms with more axes and enhanced capabilities is expected to drive further growth in the market, offering new possibilities for automation and efficiency across various industries.

Broadcast Automation, Staging (live stage), Sports, Film and TVCM, Other in the Global Robotic Arm (RA) Market:

The Global Robotic Arm (RA) Market finds extensive usage in various areas, including broadcast automation, staging (live stage), sports, film, and TVCM (television commercial), among others. In broadcast automation, robotic arms are used to operate cameras, lighting, and other equipment, ensuring smooth and precise movements during live broadcasts. This automation enhances the quality of the broadcast by providing consistent and accurate camera angles, reducing the need for manual intervention, and allowing for more creative and dynamic shots. In staging for live performances, robotic arms are employed to move props, set pieces, and even performers, creating visually stunning and intricate stage designs. These robotic arms can be programmed to execute complex choreography, adding a new dimension to live shows and enhancing the overall audience experience. In sports, robotic arms are used for various purposes, such as capturing high-speed action with precision and consistency. They can be used to operate cameras that follow athletes' movements, providing unique and dynamic angles that enhance the viewing experience for fans. In film and TVCM production, robotic arms are utilized to achieve precise and repeatable camera movements, enabling filmmakers to capture complex shots that would be difficult or impossible to achieve manually. This technology allows for greater creativity and innovation in visual storytelling, resulting in more engaging and visually appealing content. Additionally, robotic arms are used in other areas such as manufacturing, healthcare, and research, where they perform tasks that require high precision, speed, and reliability. The versatility and adaptability of robotic arms make them valuable tools in various industries, driving their widespread adoption and continued growth in the market.

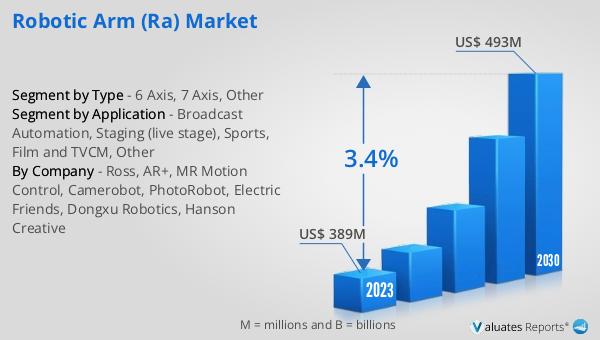

Global Robotic Arm (RA) Market Outlook:

The global Robotic Arm (RA) market is anticipated to expand from USD 403.4 million in 2024 to USD 493 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 3.4% over the forecast period. The top five global manufacturers collectively hold a market share exceeding 50%. Among the different product segments, the 6-axis robotic arm stands out as the largest, accounting for approximately 50% of the market share. This growth is driven by the increasing demand for automation across various industries, advancements in robotic technology, and the need for improved operational efficiency. The versatility and precision of 6-axis robotic arms make them highly sought after for a wide range of applications, from manufacturing and healthcare to entertainment and research. As industries continue to embrace automation to enhance productivity and reduce costs, the demand for robotic arms is expected to rise, further propelling the market's growth. The dominance of the top manufacturers underscores the competitive nature of the market, with companies continually innovating to maintain their market position and meet the evolving needs of their customers.

| Report Metric | Details |

| Report Name | Robotic Arm (RA) Market |

| Accounted market size in 2024 | US$ 403.4 million |

| Forecasted market size in 2030 | US$ 493 million |

| CAGR | 3.4 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Ross, AR+, MR Motion Control, Camerobot, PhotoRobot, Electric Friends, Dongxu Robotics, Hanson Creative |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |