What is Global Polarization-Maintaining Fiber for Fiber Optic Gyroscopes Market?

The Global Polarization-Maintaining Fiber for Fiber Optic Gyroscopes Market is a specialized segment within the broader fiber optics industry. Polarization-maintaining (PM) fibers are designed to maintain the polarization of light over long distances, which is crucial for applications requiring high precision and stability. Fiber optic gyroscopes (FOGs) are one such application, used extensively in navigation systems for aircraft, ships, and even spacecraft. These gyroscopes rely on the interference of light to measure rotation, and any disturbance in the polarization can lead to inaccurate readings. Therefore, PM fibers are essential for ensuring the reliability and accuracy of these systems. The global market for these fibers is driven by the increasing demand for high-precision navigation systems in various industries, including aerospace, defense, and automotive. As technology advances and the need for more accurate and reliable navigation systems grows, the demand for PM fibers in FOGs is expected to rise. This market is characterized by a high level of technical expertise and innovation, with companies constantly developing new types of fibers to meet the evolving needs of their customers.

Panda Fiber, Bow Tie Fiber, Elliptical Fiber, Others in the Global Polarization-Maintaining Fiber for Fiber Optic Gyroscopes Market:

Panda Fiber, Bow Tie Fiber, Elliptical Fiber, and other types of PM fibers each have unique characteristics that make them suitable for different applications within the Global Polarization-Maintaining Fiber for Fiber Optic Gyroscopes Market. Panda Fiber is one of the most commonly used types of PM fiber. It gets its name from the panda-like pattern of stress rods that are embedded in the fiber. These stress rods create a high birefringence, which helps to maintain the polarization of light. Panda Fiber is known for its high performance and reliability, making it a popular choice for many applications, including fiber optic gyroscopes. Bow Tie Fiber, on the other hand, has a different structure. It features stress rods that are shaped like a bow tie, which also creates high birefringence. This type of fiber is often used in applications where space is limited, as its design allows for a more compact form factor. Elliptical Fiber is another type of PM fiber that has an elliptical core. This unique shape helps to maintain the polarization of light by creating a difference in the refractive index between the major and minor axes of the ellipse. Elliptical Fiber is often used in applications that require high precision and stability, such as fiber optic gyroscopes. Other types of PM fibers include Photonic Crystal Fiber and Polarization-Maintaining Photonic Bandgap Fiber. These fibers use advanced technologies to achieve high birefringence and maintain the polarization of light. Photonic Crystal Fiber, for example, uses a microstructured design to create a high level of birefringence, while Polarization-Maintaining Photonic Bandgap Fiber uses a periodic structure to achieve the same effect. Each of these fibers has its own advantages and disadvantages, and the choice of fiber depends on the specific requirements of the application. In the Global Polarization-Maintaining Fiber for Fiber Optic Gyroscopes Market, the demand for these different types of fibers is driven by the need for high precision and reliability in navigation systems. As technology continues to advance, new types of PM fibers are being developed to meet the evolving needs of the market. Companies in this industry are constantly innovating and improving their products to stay ahead of the competition and provide the best possible solutions for their customers.

Single-Axis FOG, Multi-Axis FOG in the Global Polarization-Maintaining Fiber for Fiber Optic Gyroscopes Market:

The usage of Global Polarization-Maintaining Fiber for Fiber Optic Gyroscopes Market in Single-Axis FOG and Multi-Axis FOG applications is crucial for ensuring the accuracy and reliability of these systems. Single-Axis FOGs are used to measure rotation around a single axis. They are commonly used in applications such as aircraft navigation, where precise measurements of pitch, roll, and yaw are essential. The use of PM fibers in these gyroscopes helps to maintain the polarization of light, which is critical for accurate measurements. Any disturbance in the polarization can lead to errors in the readings, which can have serious consequences in applications where precision is paramount. Multi-Axis FOGs, on the other hand, are used to measure rotation around multiple axes. These gyroscopes are often used in more complex navigation systems, such as those found in spacecraft and advanced military vehicles. The use of PM fibers in Multi-Axis FOGs is even more critical, as the complexity of the system increases the potential for errors. By maintaining the polarization of light, PM fibers help to ensure that the gyroscope provides accurate and reliable measurements, even in challenging environments. In both Single-Axis and Multi-Axis FOGs, the choice of PM fiber can have a significant impact on the performance of the system. Factors such as birefringence, attenuation, and environmental stability all play a role in determining the suitability of a particular fiber for a given application. For example, Panda Fiber is often chosen for its high birefringence and reliability, while Bow Tie Fiber may be preferred for applications where space is limited. Elliptical Fiber, with its unique core shape, is often used in applications that require high precision and stability. The demand for PM fibers in Single-Axis and Multi-Axis FOGs is driven by the need for high-precision navigation systems in various industries. As technology continues to advance, the requirements for these systems are becoming more stringent, leading to an increased demand for high-performance PM fibers. Companies in the Global Polarization-Maintaining Fiber for Fiber Optic Gyroscopes Market are constantly developing new types of fibers to meet these evolving needs. By providing reliable and accurate measurements, PM fibers play a crucial role in ensuring the safety and efficiency of navigation systems in a wide range of applications.

Global Polarization-Maintaining Fiber for Fiber Optic Gyroscopes Market Outlook:

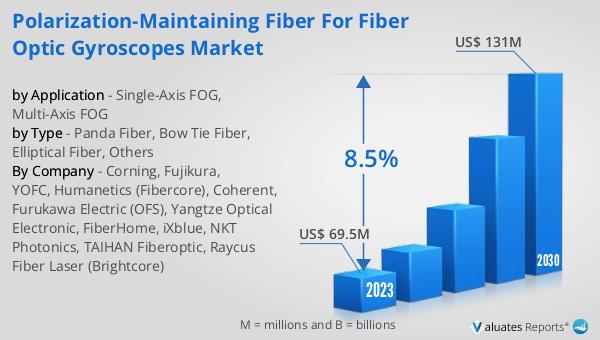

The global market for Polarization-Maintaining Fiber for Fiber Optic Gyroscopes was valued at $69.5 million in 2023 and is projected to grow significantly, reaching $131 million by 2030. This growth represents a compound annual growth rate (CAGR) of 8.5% during the forecast period from 2024 to 2030. This market outlook highlights the increasing demand for high-precision navigation systems across various industries, including aerospace, defense, and automotive. The rising need for accurate and reliable measurements in these applications is driving the demand for PM fibers, which are essential for maintaining the polarization of light in fiber optic gyroscopes. The market is characterized by a high level of technical expertise and innovation, with companies constantly developing new types of fibers to meet the evolving needs of their customers. As technology continues to advance, the demand for PM fibers in fiber optic gyroscopes is expected to grow, driving the market forward.

| Report Metric | Details |

| Report Name | Polarization-Maintaining Fiber for Fiber Optic Gyroscopes Market |

| Accounted market size in 2023 | US$ 69.5 million |

| Forecasted market size in 2030 | US$ 131 million |

| CAGR | 8.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Corning, Fujikura, YOFC, Humanetics (Fibercore), Coherent, Furukawa Electric (OFS), Yangtze Optical Electronic, FiberHome, iXblue, NKT Photonics, TAIHAN Fiberoptic, Raycus Fiber Laser (Brightcore) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |