What is Global Pressure Vacuum Vent Market?

The Global Pressure Vacuum Vent Market is a specialized segment within the broader industrial equipment market, focusing on devices designed to regulate pressure and vacuum conditions in various systems. These vents are crucial for maintaining safety and operational efficiency in industries that handle volatile or sensitive materials. They prevent over-pressurization or vacuum conditions that could lead to equipment failure or hazardous situations. The market encompasses a range of products, including pressure-only vents, vacuum-only vents, and combined pressure/vacuum vents, each tailored to specific applications and industry needs. The demand for these devices is driven by stringent safety regulations, the need for operational efficiency, and the growing complexity of industrial processes. As industries continue to evolve and expand, the importance of reliable pressure and vacuum management systems becomes increasingly critical, making the Global Pressure Vacuum Vent Market a vital component of modern industrial infrastructure.

Pressure Only, Vacuum Only, Combined Pressure/Vacuum Valves in the Global Pressure Vacuum Vent Market:

Pressure-only vents are designed to release excess pressure from a system, preventing potential damage or failure. These vents are commonly used in industries where maintaining a specific pressure range is crucial for safety and efficiency. For example, in chemical processing plants, pressure-only vents help manage the pressure within reactors and storage tanks, ensuring that the internal pressure does not exceed safe limits. Vacuum-only vents, on the other hand, are used to prevent the formation of a vacuum within a system. This is particularly important in applications where a vacuum could cause structural damage or disrupt the process. For instance, in the pharmaceutical industry, vacuum-only vents are used in storage containers to prevent the collapse of the container walls due to vacuum conditions. Combined pressure/vacuum valves offer the versatility of managing both pressure and vacuum conditions within a single device. These valves are essential in applications where both over-pressurization and vacuum conditions can occur, such as in fuel storage tanks. By providing dual functionality, combined pressure/vacuum valves enhance safety and operational efficiency, reducing the need for multiple devices and simplifying system design. The Global Pressure Vacuum Vent Market caters to a wide range of industries, each with unique requirements and challenges. As a result, manufacturers offer a variety of products with different specifications and capabilities to meet the diverse needs of their customers. The market is characterized by continuous innovation, with companies investing in research and development to improve the performance and reliability of their products. This focus on innovation ensures that pressure and vacuum management systems can keep pace with the evolving demands of modern industrial processes.

Gas Extraction, Gas Pipeline, Cabin, Others in the Global Pressure Vacuum Vent Market:

The Global Pressure Vacuum Vent Market finds extensive usage in various areas, including gas extraction, gas pipelines, cabins, and other applications. In gas extraction, pressure vacuum vents play a crucial role in maintaining the safety and efficiency of the extraction process. These vents help regulate the pressure within extraction equipment, preventing over-pressurization that could lead to equipment failure or hazardous situations. By ensuring that the pressure remains within safe limits, pressure vacuum vents contribute to the smooth and efficient operation of gas extraction processes. In gas pipelines, pressure vacuum vents are essential for maintaining the integrity of the pipeline system. They help manage the pressure within the pipeline, preventing over-pressurization that could cause leaks or ruptures. Additionally, these vents prevent the formation of vacuum conditions that could lead to pipeline collapse or other structural issues. By ensuring that the pressure within the pipeline remains stable, pressure vacuum vents enhance the safety and reliability of gas transportation. In cabins, such as those found in aircraft or spacecraft, pressure vacuum vents are used to maintain a stable and comfortable environment for occupants. These vents help regulate the pressure within the cabin, preventing over-pressurization that could cause discomfort or health issues for passengers. Additionally, they prevent the formation of vacuum conditions that could lead to structural damage or other safety concerns. By ensuring that the cabin pressure remains within safe and comfortable limits, pressure vacuum vents contribute to the overall safety and comfort of occupants. In other applications, pressure vacuum vents are used in a variety of industries to manage pressure and vacuum conditions in different systems. For example, in the food and beverage industry, these vents are used in storage tanks and processing equipment to prevent over-pressurization or vacuum conditions that could affect product quality or safety. Similarly, in the automotive industry, pressure vacuum vents are used in fuel tanks and other systems to ensure safe and efficient operation. By providing reliable pressure and vacuum management, these vents contribute to the overall safety and efficiency of various industrial processes.

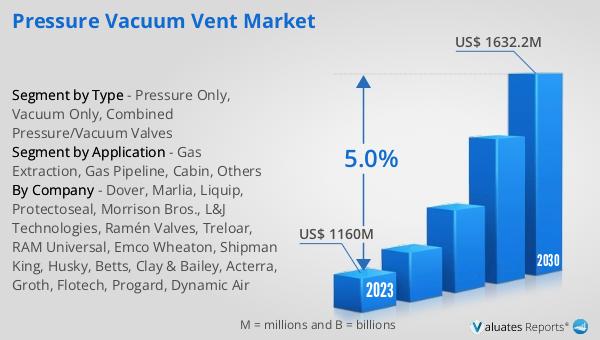

Global Pressure Vacuum Vent Market Outlook:

The global Pressure Vacuum Vent market was valued at US$ 1160 million in 2023 and is anticipated to reach US$ 1632.2 million by 2030, witnessing a CAGR of 5.0% during the forecast period 2024-2030. This market growth reflects the increasing demand for reliable pressure and vacuum management systems across various industries. As industrial processes become more complex and safety regulations become more stringent, the need for effective pressure and vacuum control solutions continues to rise. The market's growth is also driven by continuous innovation and advancements in technology, which enhance the performance and reliability of pressure vacuum vents. Manufacturers are investing in research and development to create products that can meet the evolving needs of their customers, ensuring that pressure and vacuum management systems remain a critical component of modern industrial infrastructure. The projected growth of the global Pressure Vacuum Vent market highlights the importance of these devices in maintaining safety and operational efficiency in various applications. As industries continue to evolve and expand, the demand for reliable pressure and vacuum management solutions is expected to remain strong, driving further growth and innovation in the market.

| Report Metric | Details |

| Report Name | Pressure Vacuum Vent Market |

| Accounted market size in 2023 | US$ 1160 million |

| Forecasted market size in 2030 | US$ 1632.2 million |

| CAGR | 5.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dover, Marlia, Liquip, Protectoseal, Morrison Bros., L&J Technologies, Ramén Valves, Treloar, RAM Universal, Emco Wheaton, Shipman King, Husky, Betts, Clay & Bailey, Acterra, Groth, Flotech, Progard, Dynamic Air |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |