What is Global X-ray Weighing Integrated Machine Market?

The Global X-ray Weighing Integrated Machine Market is a specialized segment within the broader industrial machinery sector, focusing on the integration of X-ray technology with weighing systems. These machines are designed to enhance the accuracy and efficiency of quality control processes across various industries. By combining X-ray imaging with precise weighing capabilities, these integrated machines offer a dual-functionality that is particularly valuable in sectors where both the internal composition and the weight of products are critical factors. The technology is widely used in food processing, pharmaceuticals, and manufacturing industries to ensure product safety, compliance with regulations, and quality assurance. The integration of X-ray and weighing systems allows for the detection of foreign objects, inconsistencies in product density, and deviations in weight, all in a single pass. This not only streamlines the inspection process but also reduces the need for multiple machines, thereby saving space and operational costs. As industries continue to prioritize efficiency and safety, the demand for such integrated solutions is expected to grow, making the Global X-ray Weighing Integrated Machine Market a key area of interest for manufacturers and investors alike.

Traditional X-ray Systems Based on 2D Imaging, CT Scanning Systems Based on 3D Imaging in the Global X-ray Weighing Integrated Machine Market:

Traditional X-ray systems based on 2D imaging have long been a staple in various industries for their ability to provide clear, detailed images of the internal structure of objects. These systems work by passing X-rays through an object and capturing the resulting image on a detector. The image produced is a two-dimensional representation of the object, which can be used to identify foreign objects, structural defects, or inconsistencies in density. In the context of the Global X-ray Weighing Integrated Machine Market, traditional 2D X-ray systems are often used in conjunction with weighing mechanisms to provide a comprehensive analysis of products. This combination allows for the simultaneous assessment of both the internal composition and the weight of an item, making it an invaluable tool for quality control in industries such as food processing and pharmaceuticals. However, while 2D imaging is effective for many applications, it does have limitations. The primary drawback is its inability to provide depth information, which can be crucial for accurately assessing complex structures or identifying issues that are not visible in a single plane. This limitation has led to the development and increasing adoption of CT scanning systems based on 3D imaging. CT scanning, or computed tomography, represents a significant advancement over traditional 2D X-ray systems. By capturing multiple X-ray images from different angles and using computer algorithms to reconstruct a three-dimensional model of the object, CT scanning provides a much more detailed and accurate representation of the internal structure. This 3D imaging capability is particularly beneficial in industries where precise measurements and detailed analysis are required. For example, in the food industry, CT scanning can be used to detect foreign objects, such as metal or glass, that may be embedded within a product, as well as to assess the uniformity of ingredients or the presence of air pockets. In the pharmaceutical industry, CT scanning can be used to verify the integrity of packaging, ensure the correct dosage of active ingredients, and detect any contamination or defects in the product. The integration of CT scanning with weighing systems in the Global X-ray Weighing Integrated Machine Market offers a powerful solution for quality control. By providing both a detailed 3D image and an accurate weight measurement, these integrated machines enable manufacturers to ensure that their products meet the highest standards of quality and safety. This dual functionality is particularly valuable in industries where regulatory compliance is critical, as it allows for the detection of potential issues before products reach the market. Despite the advantages of CT scanning, it is important to note that these systems are typically more expensive and complex than traditional 2D X-ray systems. The increased cost is due to the advanced technology and sophisticated software required to capture and process the 3D images. Additionally, the complexity of CT scanning systems means that they often require specialized training for operators, which can add to the overall cost of implementation. However, for many industries, the benefits of CT scanning in terms of improved accuracy and reliability outweigh these challenges, making it a worthwhile investment. As technology continues to advance, it is likely that the cost and complexity of CT scanning systems will decrease, making them more accessible to a wider range of industries. In conclusion, both traditional 2D X-ray systems and CT scanning systems based on 3D imaging play important roles in the Global X-ray Weighing Integrated Machine Market. While 2D systems offer a cost-effective solution for many applications, the enhanced capabilities of 3D imaging make CT scanning an increasingly attractive option for industries that require the highest levels of precision and accuracy. As the demand for integrated solutions continues to grow, manufacturers will need to carefully consider the specific needs of their industry and choose the technology that best meets their requirements.

Processed Foods, Animal-Based Foods, Plant-Based Foods in the Global X-ray Weighing Integrated Machine Market:

The Global X-ray Weighing Integrated Machine Market finds extensive application in the food industry, particularly in the areas of processed foods, animal-based foods, and plant-based foods. In the processed foods sector, these machines are used to ensure product safety and quality by detecting foreign objects, such as metal, glass, or plastic, that may have inadvertently entered the production line. The integration of X-ray technology with weighing systems allows for the simultaneous inspection of both the internal composition and the weight of processed food products, ensuring that they meet the required standards and specifications. This is particularly important in a highly regulated industry where compliance with safety and quality standards is critical. By providing a comprehensive analysis of processed foods, these integrated machines help manufacturers maintain consumer trust and avoid costly recalls. In the animal-based foods sector, the Global X-ray Weighing Integrated Machine Market plays a crucial role in ensuring the safety and quality of products such as meat, poultry, and seafood. X-ray technology is used to detect bones, shells, or other foreign objects that may be present in these products, while the weighing system ensures that each item meets the specified weight requirements. This dual functionality is particularly valuable in the meat processing industry, where the presence of bones or other foreign objects can pose a significant safety risk to consumers. By providing a thorough inspection of animal-based foods, these integrated machines help manufacturers ensure that their products are safe for consumption and meet the highest standards of quality. In the plant-based foods sector, the Global X-ray Weighing Integrated Machine Market is used to ensure the quality and consistency of products such as fruits, vegetables, grains, and plant-based meat alternatives. X-ray technology is used to detect foreign objects, such as stones, insects, or plastic, that may be present in these products, while the weighing system ensures that each item meets the specified weight requirements. This is particularly important in the plant-based foods industry, where the presence of foreign objects can compromise the quality and safety of products. By providing a comprehensive analysis of plant-based foods, these integrated machines help manufacturers maintain the integrity of their products and ensure that they meet the expectations of consumers. Overall, the Global X-ray Weighing Integrated Machine Market plays a vital role in the food industry by providing a comprehensive solution for quality control and safety assurance. By integrating X-ray technology with weighing systems, these machines offer a dual-functionality that is particularly valuable in industries where both the internal composition and the weight of products are critical factors. As the demand for safe and high-quality food products continues to grow, the use of X-ray weighing integrated machines is expected to increase, making them an essential tool for manufacturers in the processed foods, animal-based foods, and plant-based foods sectors.

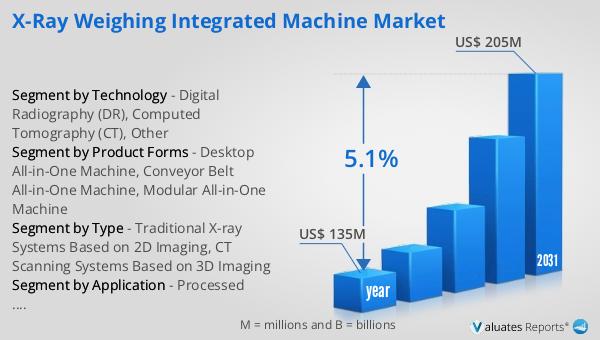

Global X-ray Weighing Integrated Machine Market Outlook:

The global market for X-ray Weighing Integrated Machines was valued at approximately $135 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $205 million by the year 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 5.1% over the forecast period. The steady increase in market size underscores the growing demand for integrated solutions that combine X-ray technology with precise weighing capabilities. This demand is driven by the need for enhanced quality control and safety assurance across various industries, including food processing, pharmaceuticals, and manufacturing. As industries continue to prioritize efficiency and compliance with regulatory standards, the adoption of X-ray weighing integrated machines is expected to rise. These machines offer a comprehensive solution for detecting foreign objects, inconsistencies in product density, and deviations in weight, all in a single pass. This not only streamlines the inspection process but also reduces the need for multiple machines, thereby saving space and operational costs. The projected growth of the Global X-ray Weighing Integrated Machine Market highlights the increasing importance of these integrated solutions in ensuring product safety and quality. As manufacturers and investors recognize the value of these machines, the market is poised for continued expansion, making it a key area of interest for stakeholders in the industrial machinery sector.

| Report Metric | Details |

| Report Name | X-ray Weighing Integrated Machine Market |

| Accounted market size in year | US$ 135 million |

| Forecasted market size in 2031 | US$ 205 million |

| CAGR | 5.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Product Forms |

|

| Segment by Technology |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Comet Yxlon, Waygate Technologies, Nordson, Anritsu Infivis, Mettler-Toledo, Eagle PI, Ishida, Thermo-fisher, Minebea Intec, Loma Systems, Sesotec GmbH, Multivac Group, Dylog Hi-Tech, Bizerba, Mekitec, Techik, WIPOTEC-OCS, Nissin Electronics, Taiyi Technology, Shanghai Weixian |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |