What is Global Transformer Insulation Film for Data Center Market?

Global Transformer Insulation Film for Data Center Market refers to the specialized films used to insulate transformers within data centers. These films are crucial because they help maintain the efficiency and safety of transformers, which are vital components in data centers. Transformers are responsible for regulating voltage levels, ensuring that the electrical equipment operates smoothly and safely. Insulation films play a key role in preventing electrical failures by providing a barrier against electrical currents, heat, and other environmental factors that could potentially damage the transformers. As data centers continue to expand globally, driven by the increasing demand for cloud computing and data storage, the need for reliable and efficient transformer insulation becomes even more critical. These films are designed to withstand high temperatures and electrical stresses, ensuring the longevity and reliability of transformers. The market for these films is growing as data centers seek to enhance their operational efficiency and reduce downtime, making transformer insulation films an essential component in the infrastructure of modern data centers.

PET, PEN, PPS, Others in the Global Transformer Insulation Film for Data Center Market:

Polyethylene Terephthalate (PET), Polyethylene Naphthalate (PEN), Polyphenylene Sulfide (PPS), and other materials are integral to the Global Transformer Insulation Film for Data Center Market. PET is widely used due to its excellent electrical insulation properties, mechanical strength, and thermal stability. It is cost-effective and offers good resistance to moisture and chemicals, making it a popular choice for transformer insulation. PET films are known for their durability and ability to withstand high temperatures, which is crucial in maintaining the efficiency of transformers in data centers. PEN, on the other hand, offers superior thermal and mechanical properties compared to PET. It is more resistant to heat and has a higher dimensional stability, making it suitable for applications where higher performance is required. PEN films are often used in environments where transformers are subjected to higher thermal and electrical stresses. PPS is another material used in transformer insulation films, known for its exceptional thermal stability and chemical resistance. It can withstand extreme temperatures and harsh environments, making it ideal for use in data centers where reliability and performance are critical. PPS films are often used in high-performance applications where other materials may not suffice. Other materials used in transformer insulation films include polyimide and aramid, which offer unique properties such as high thermal resistance and mechanical strength. These materials are often used in specialized applications where specific performance characteristics are required. The choice of material for transformer insulation films depends on various factors, including the operating environment, performance requirements, and cost considerations. As data centers continue to evolve and demand higher performance and efficiency, the development and use of advanced materials for transformer insulation films are expected to grow. These materials play a crucial role in ensuring the reliability and efficiency of transformers, which are essential components in the infrastructure of modern data centers.

Dry-type Transformer, Oil-filled Transformer in the Global Transformer Insulation Film for Data Center Market:

The usage of Global Transformer Insulation Film for Data Center Market in dry-type and oil-filled transformers is essential for ensuring the reliability and efficiency of these critical components. Dry-type transformers, which are commonly used in data centers, rely on air as the cooling medium and do not contain any liquid. This makes them safer and more environmentally friendly compared to oil-filled transformers. Insulation films in dry-type transformers provide a barrier against electrical currents and heat, ensuring that the transformer operates efficiently and safely. These films are designed to withstand high temperatures and electrical stresses, which are common in data center environments. The use of high-quality insulation films in dry-type transformers helps prevent electrical failures and extends the lifespan of the transformers, reducing maintenance costs and downtime. Oil-filled transformers, on the other hand, use oil as a cooling and insulating medium. The insulation films in these transformers play a crucial role in preventing electrical breakdowns and ensuring the safe operation of the transformer. The oil provides excellent cooling and insulation properties, but it also requires high-quality insulation films to prevent leaks and ensure the reliability of the transformer. The use of advanced materials in insulation films for oil-filled transformers helps enhance their performance and efficiency, making them suitable for use in data centers where reliability and performance are critical. Both dry-type and oil-filled transformers benefit from the use of high-quality insulation films, which help improve their efficiency, reliability, and lifespan. As data centers continue to expand and demand higher performance and efficiency, the use of advanced insulation films in transformers is expected to grow. These films play a crucial role in ensuring the reliability and efficiency of transformers, which are essential components in the infrastructure of modern data centers.

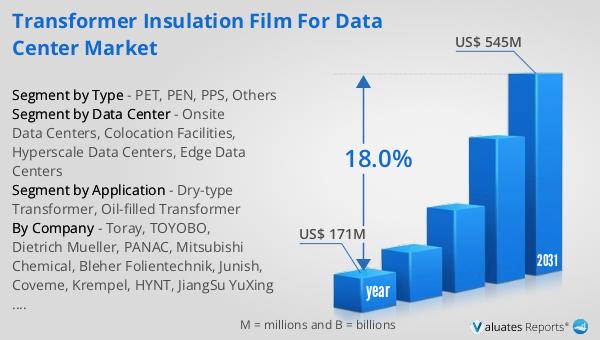

Global Transformer Insulation Film for Data Center Market Outlook:

In 2024, the global market for Transformer Insulation Film for Data Centers was valued at approximately $171 million. This market is anticipated to experience significant growth, reaching an estimated size of $545 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 18.0% over the forecast period. The increasing demand for data centers, driven by the rise in cloud computing and data storage needs, is a major factor contributing to this growth. As data centers expand, the need for reliable and efficient transformer insulation becomes more critical, driving the demand for high-quality insulation films. These films are essential for maintaining the efficiency and safety of transformers, which are vital components in data centers. The market's growth is also supported by advancements in insulation film materials, which offer improved performance and reliability. As the market continues to evolve, the development and use of advanced materials for transformer insulation films are expected to grow, further driving the market's expansion. The increasing focus on energy efficiency and sustainability in data centers is also expected to contribute to the market's growth, as insulation films play a crucial role in enhancing the efficiency and reliability of transformers.

| Report Metric | Details |

| Report Name | Transformer Insulation Film for Data Center Market |

| Accounted market size in year | US$ 171 million |

| Forecasted market size in 2031 | US$ 545 million |

| CAGR | 18.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Data Center |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toray, TOYOBO, Dietrich Mueller, PANAC, Mitsubishi Chemical, Bleher Folientechnik, Junish, Coveme, Krempel, HYNT, JiangSu YuXing Film Technology, Sichuan EM Technology, Sui On Composite Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |