What is Global Sintered Alumina Insulator Market?

The Global Sintered Alumina Insulator Market is a specialized segment within the broader electrical insulator industry, focusing on the use of sintered alumina as a primary material. Sintered alumina is a type of ceramic made by compacting and heating aluminum oxide powder until it forms a solid mass. This material is highly valued for its excellent electrical insulation properties, high thermal conductivity, and resistance to wear and corrosion. These characteristics make sintered alumina insulators ideal for use in high-temperature and high-voltage applications. The market for these insulators is driven by the growing demand for reliable and efficient electrical components across various industries, including automotive, aerospace, electronics, and industrial equipment. As technology advances and industries seek more durable and efficient materials, the demand for sintered alumina insulators is expected to grow. This market is characterized by continuous innovation and development, as manufacturers strive to enhance the performance and durability of their products to meet the evolving needs of their customers. The global reach of this market indicates its importance in supporting the infrastructure of modern technology and industry.

Unglazed Insulator, Glazed Insulator in the Global Sintered Alumina Insulator Market:

Unglazed and glazed insulators are two primary types of insulators used in the Global Sintered Alumina Insulator Market, each with distinct characteristics and applications. Unglazed insulators are typically used in environments where the risk of contamination or moisture is minimal. These insulators are made from sintered alumina without any additional coating, which allows them to maintain their natural porous surface. This porosity can be advantageous in certain applications where a rough surface is needed for better mechanical grip or where the insulator is not exposed to harsh environmental conditions. However, the lack of a protective glaze means that unglazed insulators may be more susceptible to dirt accumulation and moisture absorption, which can affect their performance over time. On the other hand, glazed insulators are coated with a layer of glass or ceramic glaze, which provides a smooth, non-porous surface. This glaze acts as a protective barrier against environmental factors such as moisture, dirt, and chemical exposure, making glazed insulators suitable for outdoor and high-contamination environments. The glazing process enhances the insulator's durability and longevity, ensuring consistent performance even in challenging conditions. In the Global Sintered Alumina Insulator Market, the choice between unglazed and glazed insulators depends on the specific requirements of the application, including environmental conditions, mechanical stress, and electrical performance needs. Manufacturers in this market are continually innovating to improve the properties of both unglazed and glazed insulators, aiming to provide solutions that meet the diverse needs of their customers. This includes developing new glazing materials and techniques to enhance the protective qualities of glazed insulators, as well as optimizing the composition and manufacturing processes of unglazed insulators to improve their mechanical and electrical properties. As industries continue to demand more reliable and efficient insulators, the Global Sintered Alumina Insulator Market is expected to see ongoing growth and development in both unglazed and glazed product offerings.

Automotive, Aerospace & Defense, Electronics, Industrial Equipment, Medical Devices, Others in the Global Sintered Alumina Insulator Market:

The Global Sintered Alumina Insulator Market finds extensive usage across various industries, each benefiting from the unique properties of sintered alumina insulators. In the automotive industry, these insulators are used in electric vehicles and hybrid cars, where they help manage the high voltages and temperatures associated with electric powertrains. Their ability to withstand extreme conditions makes them ideal for use in battery management systems, power electronics, and electric motors. In the aerospace and defense sectors, sintered alumina insulators are used in aircraft and military equipment, where reliability and performance are critical. These insulators provide excellent thermal and electrical insulation, ensuring the safe and efficient operation of avionics, communication systems, and other electronic components. In the electronics industry, sintered alumina insulators are used in a wide range of applications, from consumer electronics to industrial electronics. Their high thermal conductivity and electrical insulation properties make them suitable for use in semiconductors, circuit boards, and other electronic components that require efficient heat dissipation and electrical isolation. In the industrial equipment sector, sintered alumina insulators are used in machinery and equipment that operate under high temperatures and voltages. Their durability and resistance to wear and corrosion make them ideal for use in harsh industrial environments, where they help ensure the safe and efficient operation of equipment. In the medical devices industry, sintered alumina insulators are used in diagnostic and therapeutic equipment, where they provide reliable electrical insulation and thermal management. Their biocompatibility and resistance to chemical exposure make them suitable for use in medical applications, where safety and performance are paramount. Other industries that benefit from the use of sintered alumina insulators include telecommunications, energy, and transportation, where these insulators help improve the efficiency and reliability of electrical systems. As technology continues to advance and industries seek more efficient and durable materials, the Global Sintered Alumina Insulator Market is expected to see continued growth and innovation, with new applications and opportunities emerging across various sectors.

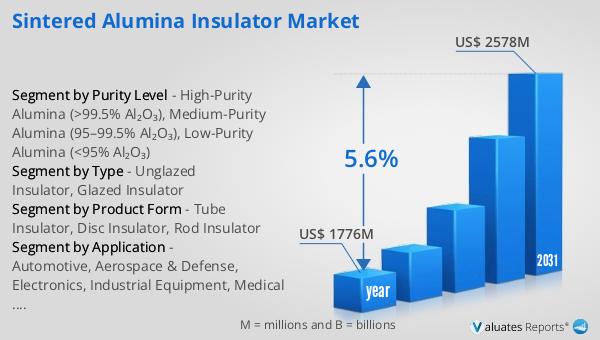

Global Sintered Alumina Insulator Market Outlook:

The global market for Sintered Alumina Insulator was valued at $1,776 million in 2024 and is anticipated to expand to a revised size of $2,578 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.6% during the forecast period. This growth trajectory underscores the increasing demand for sintered alumina insulators across various industries, driven by their superior electrical insulation properties, high thermal conductivity, and resistance to wear and corrosion. As industries continue to evolve and seek more efficient and durable materials, the demand for sintered alumina insulators is expected to rise, supporting the market's growth. The projected expansion of the market highlights the importance of sintered alumina insulators in supporting the infrastructure of modern technology and industry. Manufacturers in this market are continually innovating to enhance the performance and durability of their products, aiming to meet the evolving needs of their customers. This includes developing new materials and manufacturing processes to improve the properties of sintered alumina insulators, ensuring their continued relevance and competitiveness in the global market. As the market continues to grow, it presents opportunities for manufacturers to expand their product offerings and reach new customers, further driving the growth of the Global Sintered Alumina Insulator Market.

| Report Metric | Details |

| Report Name | Sintered Alumina Insulator Market |

| Accounted market size in year | US$ 1776 million |

| Forecasted market size in 2031 | US$ 2578 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Product Form |

|

| Segment by Purity Level |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CoorsTek (USA), CeramTec (Germany), Kyocera (Japan), NGK Insulators (Japan), Niterra (Japan), IBIDEN Fine Ceramics (Japan), Morgan Advanced Materials (UK), Saint-Gobain (France), AdTech Ceramics (USA), McDanel Advanced Ceramic (USA), Ortech Advanced Ceramics (USA), Superior Technical Ceramics (USA), Rauschert (Germany), Schunk Group (Germany), Carborundum (India), Jyoti Ceramic (India), UNIPRETEC (China), Jinghui Industry (China) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |