What is Global PCB Marking Equipment Market?

The Global PCB Marking Equipment Market refers to the worldwide industry focused on the production and distribution of equipment used to mark printed circuit boards (PCBs). PCBs are essential components in virtually all electronic devices, serving as the backbone that connects various electronic components. Marking equipment is crucial in this context as it ensures that each PCB is properly labeled with information such as serial numbers, barcodes, and other identifiers. This labeling is vital for tracking, quality control, and compliance with industry standards. The market for PCB marking equipment is driven by the increasing demand for electronic devices across various sectors, including consumer electronics, automotive, telecommunications, and healthcare. As technology advances, the need for more sophisticated and precise marking solutions grows, pushing manufacturers to innovate and improve their offerings. The market is characterized by a range of technologies and solutions, each catering to different needs and preferences of manufacturers. With the globalization of the electronics industry, the demand for efficient and reliable PCB marking equipment is expected to continue rising, making it a dynamic and evolving market.

Laser Marking, Inkjet Marking, Others in the Global PCB Marking Equipment Market:

Laser marking, inkjet marking, and other methods are integral to the Global PCB Marking Equipment Market, each offering unique advantages and applications. Laser marking is a popular choice due to its precision and permanence. It uses a focused beam of light to etch information onto the surface of a PCB. This method is highly accurate, capable of producing detailed and intricate markings without physical contact with the board, which minimizes the risk of damage. Laser marking is also versatile, suitable for a wide range of materials and capable of producing both alphanumeric characters and complex graphics. Its permanence makes it ideal for applications where long-lasting identification is crucial, such as in aerospace and medical devices. Inkjet marking, on the other hand, involves spraying tiny droplets of ink onto the PCB to create the desired markings. This method is known for its speed and flexibility, allowing for quick changes in the information being printed. Inkjet marking is particularly useful in high-volume production environments where time efficiency is critical. It can handle a variety of inks, including those that are resistant to high temperatures and chemicals, making it suitable for diverse industrial applications. However, the markings produced by inkjet are generally less durable than those created by laser marking, which can be a consideration in environments where the boards are exposed to harsh conditions. Other marking methods in the PCB market include mechanical engraving and thermal transfer. Mechanical engraving involves physically cutting into the surface of the PCB to create markings. This method is less common due to its potential to damage the board and its slower speed compared to laser and inkjet methods. However, it can be useful for specific applications where deep, tactile markings are required. Thermal transfer marking uses heat to transfer ink from a ribbon onto the PCB. This method is valued for its ability to produce high-contrast, durable markings that are resistant to smudging and fading. It is often used in applications where readability and durability are paramount. Each of these methods has its own set of advantages and limitations, and the choice of which to use often depends on the specific requirements of the application, including factors such as production volume, material type, and environmental conditions. As the PCB marking equipment market continues to evolve, manufacturers are constantly seeking ways to enhance the capabilities and efficiency of these technologies, ensuring they meet the ever-changing needs of the electronics industry.

in the Global PCB Marking Equipment Market:

The applications of Global PCB Marking Equipment are vast and varied, reflecting the diverse industries that rely on printed circuit boards. In the consumer electronics sector, PCB marking equipment is essential for the production of devices such as smartphones, tablets, and laptops. These devices require precise and reliable markings to ensure traceability and compliance with regulatory standards. The automotive industry also heavily relies on PCB marking equipment, as modern vehicles are equipped with numerous electronic components that require accurate identification for quality control and maintenance purposes. In telecommunications, PCB marking is crucial for the production of equipment such as routers, switches, and base stations. These components must be clearly marked to facilitate installation, maintenance, and troubleshooting. The healthcare industry is another significant user of PCB marking equipment, as medical devices often contain complex electronic systems that require precise labeling for safety and regulatory compliance. In industrial applications, PCB marking equipment is used to produce control systems, sensors, and other electronic components that are essential for automation and process control. The aerospace industry also benefits from PCB marking equipment, as it ensures that critical electronic components are properly identified and traceable throughout their lifecycle. Additionally, the defense sector relies on PCB marking for the production of military-grade electronics, where durability and reliability are paramount. Each of these applications has specific requirements and challenges, driving the need for versatile and adaptable marking solutions. As technology continues to advance, the demand for sophisticated PCB marking equipment is expected to grow, further expanding its applications across various industries.

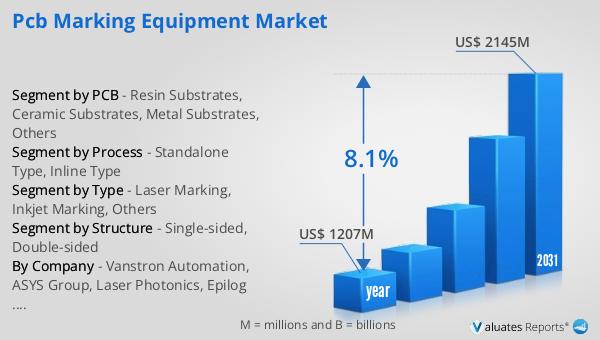

Global PCB Marking Equipment Market Outlook:

In 2024, the global market for PCB Marking Equipment was valued at approximately $1,207 million. Looking ahead, this market is anticipated to expand significantly, reaching an estimated size of $2,145 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.1% over the forecast period. This robust growth can be attributed to several factors, including the increasing demand for electronic devices across various sectors, the need for precise and reliable marking solutions, and the ongoing advancements in marking technologies. As industries continue to evolve and embrace digital transformation, the importance of efficient and accurate PCB marking becomes even more critical. The market's expansion is also driven by the globalization of the electronics industry, which necessitates standardized and compliant marking practices. As a result, manufacturers are investing in advanced marking equipment to meet these demands and stay competitive in the global market. The projected growth of the PCB marking equipment market underscores its vital role in the electronics manufacturing ecosystem and highlights the ongoing need for innovation and improvement in this field.

| Report Metric | Details |

| Report Name | PCB Marking Equipment Market |

| Accounted market size in year | US$ 1207 million |

| Forecasted market size in 2031 | US$ 2145 million |

| CAGR | 8.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Process |

|

| Segment by Structure |

|

| Segment by PCB |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Vanstron Automation, ASYS Group, Laser Photonics, Epilog Laser, Trotec Laser, HiPA Photonics, Farley Laserlab, LASIT, OSAI Automation, Han's Laser, Hymson Laser Technology, Wuhan HGLaser Engineering, Dongguan Mactron Technology, Shenzhen Ruitian Laser, Guangdong Fly Laser Intelligent Equipment, Wuhan Hero Optoelectronics Technology, Shenzhen Herolaser Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |