What is Global Moisture Displacing Rust Preventative Market?

The Global Moisture Displacing Rust Preventative Market is a specialized segment within the broader corrosion protection industry, focusing on products designed to prevent rust by displacing moisture. These products are crucial in environments where metal surfaces are exposed to moisture, which can lead to rust and corrosion over time. The market encompasses a variety of formulations, including oil-based, solvent-based, and water-based solutions, each tailored to specific applications and environmental conditions. The demand for these products is driven by industries such as automotive, aerospace, marine, and manufacturing, where the longevity and integrity of metal components are paramount. As industries continue to expand globally, the need for effective rust prevention solutions grows, making this market an essential component of industrial maintenance and protection strategies. The market's growth is also fueled by advancements in technology, leading to more efficient and environmentally friendly products that meet stringent regulatory standards. Overall, the Global Moisture Displacing Rust Preventative Market plays a vital role in extending the lifespan of metal products and infrastructure, thereby reducing maintenance costs and enhancing safety.

Oil-Based, Solvent-Based, Water-Based in the Global Moisture Displacing Rust Preventative Market:

In the Global Moisture Displacing Rust Preventative Market, products are categorized based on their formulation: oil-based, solvent-based, and water-based. Each type has distinct characteristics and applications, catering to different industrial needs. Oil-based rust preventatives are known for their excellent water displacement properties and long-lasting protection. They form a protective barrier on metal surfaces, effectively sealing out moisture and preventing rust. These products are particularly favored in industries where long-term storage of metal parts is common, such as in automotive and machinery sectors. Their application is straightforward, often requiring minimal surface preparation, which makes them a cost-effective solution for many businesses. However, oil-based products can be challenging to remove and may not be suitable for all environments due to their potential environmental impact. Solvent-based rust preventatives, on the other hand, offer quick-drying properties and are easy to apply. They are typically used in situations where rapid handling of parts is necessary, such as in assembly lines or during maintenance operations. The solvents in these products evaporate quickly, leaving behind a thin protective film that guards against moisture and corrosion. This makes them ideal for use in environments where downtime needs to be minimized. However, the use of solvents raises concerns about volatile organic compounds (VOCs) emissions, which can be harmful to both the environment and human health. As a result, there is a growing trend towards developing low-VOC or VOC-free solvent-based products to meet regulatory requirements and environmental standards. Water-based rust preventatives are gaining popularity due to their environmentally friendly nature. These products use water as a carrier instead of oil or solvents, significantly reducing VOC emissions and making them safer for both users and the environment. Water-based solutions are particularly suitable for industries with stringent environmental regulations, such as aerospace and electronics. They provide effective rust protection while being easy to clean and remove, which is an advantage in applications where parts need to be painted or coated after rust prevention treatment. Despite their benefits, water-based products may require more precise application techniques and conditions to ensure optimal performance, as they can be less forgiving than their oil or solvent-based counterparts in terms of application errors. Each type of rust preventative has its own set of advantages and limitations, and the choice between them often depends on specific application requirements, environmental considerations, and regulatory compliance. As the Global Moisture Displacing Rust Preventative Market continues to evolve, manufacturers are investing in research and development to create more advanced formulations that offer enhanced protection, ease of use, and reduced environmental impact. This ongoing innovation is crucial for meeting the diverse needs of industries worldwide and ensuring the continued growth and relevance of the market.

Dip Type, Spray Type, Brush Type in the Global Moisture Displacing Rust Preventative Market:

The usage of Global Moisture Displacing Rust Preventative Market products varies significantly depending on the application method, which includes dip type, spray type, and brush type. Each method offers unique advantages and is chosen based on the specific requirements of the task at hand. Dip type application involves immersing the metal parts into a tank filled with the rust preventative solution. This method ensures complete coverage of the parts, including hard-to-reach areas, making it ideal for complex shapes and assemblies. It is commonly used in manufacturing and automotive industries where large volumes of parts need to be treated efficiently. The dip type method is particularly effective for small to medium-sized components, providing a uniform coating that offers reliable protection against moisture and corrosion. However, it requires significant setup and maintenance of the dipping equipment, which can be a consideration for some businesses. Spray type application is another popular method, especially for larger surfaces or when precision is required. This method involves using spray equipment to apply the rust preventative solution evenly across the metal surface. It is highly versatile and can be used in various settings, from industrial plants to field operations. Spray type application is favored for its speed and efficiency, allowing for quick treatment of large areas with minimal labor. It is particularly useful in situations where parts cannot be easily moved or immersed, such as in construction or marine environments. The spray method also allows for easy control of the coating thickness, which can be adjusted to meet specific protection requirements. However, it may require specialized equipment and training to ensure proper application and avoid overspray or wastage. Brush type application is the most straightforward method, involving the manual application of the rust preventative solution using a brush. This method is ideal for small-scale applications or touch-up work where precision is crucial. It allows for targeted application, making it suitable for intricate parts or areas that require special attention. Brush type application is commonly used in maintenance and repair operations, where quick and easy application is necessary. It is also a cost-effective solution for small businesses or individual users who do not require large-scale treatment. However, the manual nature of this method can be time-consuming and may not provide the same level of uniformity as dip or spray methods, especially for larger surfaces. Each application method has its own set of benefits and challenges, and the choice often depends on factors such as the size and complexity of the parts, the available equipment, and the specific requirements of the project. As the Global Moisture Displacing Rust Preventative Market continues to grow, manufacturers are developing new application technologies and techniques to enhance the effectiveness and efficiency of rust prevention solutions. This ongoing innovation is essential for meeting the diverse needs of industries worldwide and ensuring the continued success of rust preventative products in various applications.

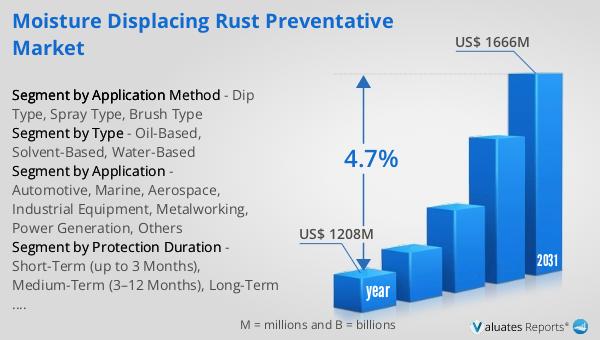

Global Moisture Displacing Rust Preventative Market Outlook:

The global market for Moisture Displacing Rust Preventative was valued at $1,208 million in 2024 and is anticipated to expand to a revised size of $1,666 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.7% during the forecast period. This growth trajectory underscores the increasing demand for effective rust prevention solutions across various industries. As businesses and industries continue to prioritize the longevity and integrity of their metal components, the need for reliable rust preventative products becomes more pronounced. The market's expansion is driven by several factors, including technological advancements, increased industrialization, and the growing awareness of the importance of corrosion protection. Additionally, the shift towards environmentally friendly and sustainable products is influencing the development of new formulations that meet both performance and regulatory standards. The projected growth of the market highlights the critical role that moisture displacing rust preventatives play in maintaining the durability and safety of metal structures and components. As industries evolve and new challenges emerge, the demand for innovative and effective rust prevention solutions is expected to continue rising, ensuring the market's relevance and importance in the years to come.

| Report Metric | Details |

| Report Name | Moisture Displacing Rust Preventative Market |

| Accounted market size in year | US$ 1208 million |

| Forecasted market size in 2031 | US$ 1666 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Protection Duration |

|

| Segment by Application Method |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ITW Pro Brands (USA), Quaker Houghton (USA), FUCHS Lubricants (Germany), Castrol Limited (UK), CRC Industries (USA), WD-40 Company (USA), Henkel (Germany), Chemetall (Germany), Socomore (France), 3M Company (USA), Daubert Cromwell (USA), Vantage Specialty Chemicals (USA), Birchwood Technologies (USA), Chautauqua Chemicals (USA), Du-Lite Corporation (USA), Zep Inc. (USA), Corrosion Technologies (USA) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |