What is Global Microglass Filter Market?

The Global Microglass Filter Market is a specialized segment within the broader filtration industry, focusing on filters made from microglass fibers. These filters are renowned for their exceptional ability to capture and retain fine particles, making them indispensable in various applications where air and liquid purity is paramount. Microglass filters are composed of fine glass fibers that are intricately woven to create a dense matrix, allowing for high-efficiency filtration. This market is driven by the increasing demand for clean air and fluids across industries such as automotive, pharmaceuticals, and food and beverage. The versatility of microglass filters, which can be tailored to meet specific filtration needs, further propels their adoption. As industries continue to prioritize sustainability and regulatory compliance, the demand for efficient filtration solutions like microglass filters is expected to grow. The market is characterized by continuous innovation, with manufacturers striving to enhance filter performance and durability while reducing environmental impact. Overall, the Global Microglass Filter Market plays a crucial role in ensuring the safety, efficiency, and sustainability of various industrial processes.

Single-layer Microglass Filter, Multi-layer Microglass Filter in the Global Microglass Filter Market:

Single-layer and multi-layer microglass filters are two primary types of filters within the Global Microglass Filter Market, each offering distinct advantages and applications. Single-layer microglass filters consist of a single sheet of microglass fibers, providing a straightforward and cost-effective solution for basic filtration needs. These filters are typically used in applications where moderate filtration efficiency is sufficient, such as in certain HVAC systems and industrial processes. The simplicity of single-layer filters makes them easy to manufacture and replace, contributing to their widespread use in less demanding environments. On the other hand, multi-layer microglass filters are designed for more complex and demanding filtration tasks. These filters comprise multiple layers of microglass fibers, each with varying densities and fiber diameters, to achieve a gradient filtration effect. This design allows for the capture of a broader range of particle sizes, enhancing overall filtration efficiency. Multi-layer filters are particularly valuable in applications where high levels of purity are required, such as in pharmaceutical manufacturing, food and beverage processing, and critical industrial operations. The layered structure of these filters not only improves particle retention but also extends the filter's lifespan by distributing the filtration load across multiple layers. This results in reduced maintenance costs and downtime, making multi-layer filters a preferred choice for industries with stringent filtration requirements. The choice between single-layer and multi-layer microglass filters depends on several factors, including the specific application, desired filtration efficiency, and budget constraints. While single-layer filters offer a cost-effective solution for basic filtration needs, multi-layer filters provide superior performance and longevity for more demanding applications. As industries continue to evolve and prioritize efficiency and sustainability, the demand for both types of microglass filters is expected to grow, with manufacturers continually innovating to meet the diverse needs of their customers.

HVAC System, Pharmaceutical, Food & Beverage, Oil & Gas, Industrial, Automotive, Others in the Global Microglass Filter Market:

The Global Microglass Filter Market finds extensive usage across various sectors, each benefiting from the unique properties of microglass filters. In HVAC systems, microglass filters play a crucial role in maintaining indoor air quality by capturing airborne particles such as dust, pollen, and mold spores. This is particularly important in commercial and residential buildings where clean air is essential for occupant health and comfort. In the pharmaceutical industry, microglass filters are used to ensure the purity of air and liquids during the manufacturing process. These filters help prevent contamination, ensuring that pharmaceutical products meet stringent quality standards. Similarly, in the food and beverage industry, microglass filters are employed to maintain the purity of ingredients and finished products. They help remove impurities and contaminants, ensuring that food and beverages are safe for consumption. In the oil and gas sector, microglass filters are used to filter out particulates and contaminants from fluids, ensuring the smooth operation of equipment and preventing damage. The industrial sector also relies on microglass filters for various applications, including air and liquid filtration in manufacturing processes. These filters help maintain equipment efficiency and product quality by removing contaminants that could cause damage or defects. In the automotive industry, microglass filters are used in air intake systems and cabin air filters to improve air quality and protect engine components. Finally, microglass filters are used in a variety of other applications, including water treatment, electronics manufacturing, and chemical processing. Their versatility and efficiency make them an essential component in many industries, contributing to improved product quality, equipment longevity, and environmental sustainability.

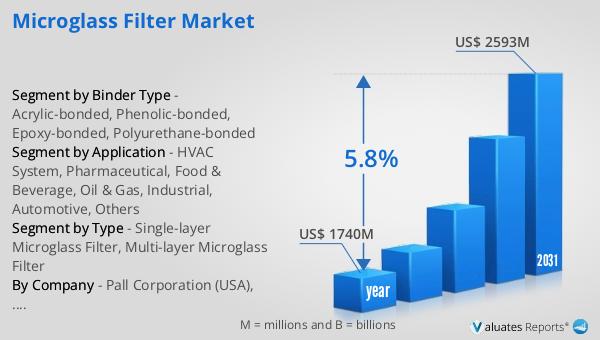

Global Microglass Filter Market Outlook:

The global market for microglass filters was valued at $1,740 million in 2024 and is anticipated to expand to a revised size of $2,593 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.8% over the forecast period. This growth trajectory underscores the increasing demand for high-efficiency filtration solutions across various industries. As businesses and consumers alike become more conscious of the importance of air and fluid purity, the adoption of microglass filters is expected to rise. The market's expansion is driven by several factors, including the growing emphasis on sustainability, regulatory compliance, and the need for improved product quality and operational efficiency. Manufacturers are continually innovating to enhance the performance and durability of microglass filters, ensuring they meet the evolving needs of their customers. The projected growth of the Global Microglass Filter Market highlights the critical role these filters play in ensuring the safety, efficiency, and sustainability of industrial processes. As industries continue to prioritize clean air and fluids, the demand for microglass filters is expected to remain strong, driving further innovation and development in the market.

| Report Metric | Details |

| Report Name | Microglass Filter Market |

| Accounted market size in year | US$ 1740 million |

| Forecasted market size in 2031 | US$ 2593 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Binder Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Pall Corporation (USA), Parker Hannifin (USA), Donaldson Company (USA), Sartorius Group (Germany), Eaton Corporation (USA), 3M Company (USA), Mann+Hummel (Germany), Filtration Group (USA), Hollingsworth & Vose (USA), Swift Filters (USA), Filson Filters (China), Xinxiang North Filter (China), Henan Sinofiltec (China), Norman Filter (USA), Hengst Filtration (Germany), Fleetguard Filters (India) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |