What is Global Lattice Girder Welding Machine Market?

The Global Lattice Girder Welding Machine Market refers to the worldwide industry focused on the production, distribution, and utilization of machines specifically designed for welding lattice girders. Lattice girders are structural components used in construction to provide support and stability, often seen in large-scale infrastructure projects like bridges, tunnels, and buildings. These machines are essential in automating the welding process, ensuring precision, efficiency, and consistency in the production of lattice girders. The market encompasses various types of welding machines, each tailored to different specifications and requirements, catering to diverse construction needs. As infrastructure development continues to grow globally, the demand for these machines is expected to rise, driven by the need for faster construction processes and the increasing complexity of modern architectural designs. The market is characterized by technological advancements, with manufacturers continually innovating to improve machine capabilities, reduce operational costs, and enhance safety features. This dynamic market plays a crucial role in the construction industry, supporting the creation of robust and reliable structures that meet the demands of contemporary engineering challenges.

Below 200mm, 200mm-300mm, Above 300mm in the Global Lattice Girder Welding Machine Market:

The Global Lattice Girder Welding Machine Market is segmented based on the welding capacity, which is categorized into three main types: Below 200mm, 200mm-300mm, and Above 300mm. Each category serves different construction needs and project scales. Machines with a capacity Below 200mm are typically used for smaller projects or where the lattice girders required are of a smaller dimension. These machines are often more compact and cost-effective, making them suitable for projects with budget constraints or where space is limited. They are ideal for residential construction or smaller commercial buildings where the structural demands are not as intense as larger projects. The 200mm-300mm category represents a mid-range capacity, offering a balance between size and strength. These machines are versatile and can be used in a variety of construction projects, including medium-sized commercial buildings, infrastructure projects like roads and bridges, and even some industrial applications. They provide a good compromise between cost and capability, making them a popular choice for many construction firms. Machines in this category are often equipped with advanced features that enhance their efficiency and precision, such as automated controls and enhanced safety mechanisms. The Above 300mm category includes machines designed for heavy-duty applications, where large-scale lattice girders are required. These machines are used in major infrastructure projects such as high-speed rail networks, large bridges, and skyscrapers. They are built to handle the demands of producing large and robust girders that can support significant loads and withstand harsh environmental conditions. These machines are typically more expensive and require a higher level of expertise to operate, but they offer unmatched strength and durability, making them indispensable for large-scale construction projects. The demand for each category of machine is influenced by various factors, including the scale and type of construction projects, regional construction trends, and technological advancements in welding technology. As construction projects become more ambitious and complex, the need for machines with higher capacities and advanced features is expected to grow. Manufacturers in the Global Lattice Girder Welding Machine Market are continually innovating to meet these demands, developing machines that offer greater precision, efficiency, and safety. This segmentation allows construction companies to choose the right machine for their specific needs, ensuring that they can meet project requirements while optimizing costs and resources. The market for these machines is highly competitive, with numerous manufacturers vying for market share by offering machines that cater to the diverse needs of the construction industry. As a result, buyers have a wide range of options to choose from, allowing them to find machines that best fit their project specifications and budget constraints.

Prefabricated Buildings, High-speed Rail, Others in the Global Lattice Girder Welding Machine Market:

The Global Lattice Girder Welding Machine Market finds extensive usage in various areas, including prefabricated buildings, high-speed rail, and other infrastructure projects. In the realm of prefabricated buildings, these machines play a crucial role in the efficient production of structural components. Prefabrication involves manufacturing building elements in a controlled environment before transporting them to the construction site for assembly. Lattice girder welding machines ensure that the girders used in these prefabricated elements are produced with high precision and consistency, which is essential for maintaining the structural integrity of the buildings. The use of these machines in prefabrication helps reduce construction time and costs, as well as minimize waste, making it an attractive option for developers looking to streamline their building processes. In high-speed rail projects, lattice girder welding machines are indispensable due to the demanding structural requirements of rail infrastructure. High-speed rail systems require robust and reliable support structures to ensure safety and performance at high velocities. Lattice girders, welded with precision and strength, provide the necessary support for tracks and bridges, enabling trains to operate smoothly and safely. The use of advanced welding machines in this sector ensures that the girders meet stringent quality standards, which is critical for the long-term durability and safety of the rail network. The machines' ability to produce large and strong girders efficiently makes them a vital component in the construction of high-speed rail systems worldwide. Beyond prefabricated buildings and high-speed rail, lattice girder welding machines are used in a variety of other construction projects. These include bridges, tunnels, and industrial facilities, where the need for strong and reliable structural components is paramount. The versatility of these machines allows them to be adapted for different project requirements, making them a valuable asset in the construction industry. Their ability to produce girders of varying sizes and strengths means they can be used in a wide range of applications, from small-scale residential projects to large-scale infrastructure developments. The use of lattice girder welding machines in these areas not only enhances the efficiency and quality of construction but also contributes to the overall safety and longevity of the structures being built. As construction projects continue to evolve and grow in complexity, the demand for these machines is expected to increase, driven by the need for innovative solutions that can meet the challenges of modern engineering.

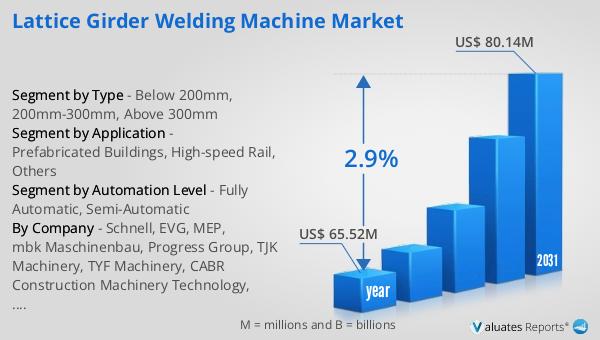

Global Lattice Girder Welding Machine Market Outlook:

The global market for Lattice Girder Welding Machines was valued at approximately $65.52 million in 2024. This market is anticipated to expand, reaching an estimated size of $80.14 million by the year 2031. This growth is projected to occur at a compound annual growth rate (CAGR) of 2.9% over the forecast period. This steady growth reflects the increasing demand for lattice girder welding machines across various construction sectors. As infrastructure projects become more ambitious and complex, the need for efficient and reliable welding machines is expected to rise. The market's expansion is driven by several factors, including technological advancements in welding technology, the growing trend of prefabricated construction, and the increasing focus on infrastructure development worldwide. Manufacturers are continually innovating to enhance machine capabilities, offering features that improve precision, efficiency, and safety. This innovation is crucial in meeting the evolving needs of the construction industry, where the demand for high-quality structural components is paramount. The market's growth also highlights the importance of lattice girder welding machines in supporting the construction of robust and reliable structures, which are essential for modern engineering challenges. As the market continues to evolve, it presents opportunities for manufacturers to expand their product offerings and cater to the diverse needs of the construction industry.

| Report Metric | Details |

| Report Name | Lattice Girder Welding Machine Market |

| Accounted market size in year | US$ 65.52 million |

| Forecasted market size in 2031 | US$ 80.14 million |

| CAGR | 2.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Automation Level |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Schnell, EVG, MEP, mbk Maschinenbau, Progress Group, TJK Machinery, TYF Machinery, CABR Construction Machinery Technology, Zhejiang Jinggong Technology, Ningbo Xinzhou Welding Equipment, Jiaoyang Welding Industries, Chengdu Gute Machinery Works |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |