What is Global Inspection Robot for Electric Power Market?

The Global Inspection Robot for Electric Power Market is a rapidly evolving sector that focuses on the development and deployment of robotic systems designed to inspect and maintain electric power infrastructure. These robots are engineered to perform a variety of tasks, such as monitoring, diagnosing, and reporting on the condition of power lines, substations, and other critical components of the electric power grid. The primary goal of these inspection robots is to enhance the reliability and efficiency of power delivery systems while minimizing the risks associated with manual inspections. By utilizing advanced technologies such as artificial intelligence, machine learning, and sensor integration, these robots can operate in challenging environments and provide real-time data to operators. This data-driven approach allows for predictive maintenance, reducing downtime and preventing potential failures. As the demand for electricity continues to grow globally, the need for efficient and reliable inspection solutions becomes increasingly important. The market for these robots is driven by the need to modernize aging infrastructure, improve safety standards, and reduce operational costs. With ongoing advancements in robotics and automation, the Global Inspection Robot for Electric Power Market is poised for significant growth in the coming years.

Outdoor Inspection, Indoor Inspection in the Global Inspection Robot for Electric Power Market:

Outdoor inspection in the Global Inspection Robot for Electric Power Market involves the deployment of robots in open environments to assess the condition of various components of the electric power infrastructure. These robots are designed to withstand harsh weather conditions, such as rain, snow, and extreme temperatures, ensuring they can operate effectively in diverse climates. Equipped with high-resolution cameras, thermal imaging sensors, and LIDAR technology, outdoor inspection robots can capture detailed images and data of power lines, towers, and other structures. This information is crucial for identifying potential issues such as corrosion, structural damage, or vegetation encroachment that could lead to power outages or safety hazards. By automating the inspection process, these robots reduce the need for human workers to perform dangerous tasks, such as climbing towers or working near high-voltage lines. This not only enhances safety but also increases the efficiency and accuracy of inspections. Indoor inspection, on the other hand, focuses on the evaluation of equipment and systems located within substations and other enclosed facilities. Indoor inspection robots are typically smaller and more agile, allowing them to navigate tight spaces and complex environments. They are equipped with sensors and cameras to monitor the condition of transformers, switchgear, and other critical components. These robots can detect anomalies such as overheating, electrical discharge, or mechanical wear, enabling operators to address issues before they escalate into major problems. The use of indoor inspection robots also minimizes the need for human intervention in potentially hazardous environments, reducing the risk of accidents and improving overall safety. Both outdoor and indoor inspection robots play a vital role in maintaining the reliability and efficiency of the electric power grid. By providing accurate and timely data, these robots enable operators to make informed decisions about maintenance and repairs, ultimately enhancing the performance and longevity of the infrastructure. As technology continues to advance, the capabilities of these robots are expected to expand, offering even greater benefits to the electric power industry.

Substation Inspection, Transmission Line Inspection, Distribution Station Inspection in the Global Inspection Robot for Electric Power Market:

The usage of Global Inspection Robots for Electric Power Market in substation inspection involves the deployment of advanced robotic systems to monitor and assess the condition of equipment and infrastructure within substations. These robots are equipped with high-resolution cameras, thermal imaging sensors, and other diagnostic tools to detect anomalies such as overheating, electrical discharge, or mechanical wear. By providing real-time data, these robots enable operators to identify potential issues before they escalate into major problems, reducing the risk of power outages and improving overall reliability. In transmission line inspection, robots are used to assess the condition of power lines and towers, identifying potential issues such as corrosion, structural damage, or vegetation encroachment. Equipped with LIDAR technology and other advanced sensors, these robots can capture detailed images and data, allowing operators to make informed decisions about maintenance and repairs. By automating the inspection process, these robots reduce the need for human workers to perform dangerous tasks, such as climbing towers or working near high-voltage lines, enhancing safety and efficiency. In distribution station inspection, robots are used to monitor the condition of equipment and systems within distribution stations, ensuring they operate efficiently and reliably. These robots can detect anomalies such as overheating, electrical discharge, or mechanical wear, enabling operators to address issues before they escalate into major problems. By providing accurate and timely data, these robots enable operators to make informed decisions about maintenance and repairs, ultimately enhancing the performance and longevity of the infrastructure. The use of inspection robots in these areas not only improves safety and efficiency but also reduces operational costs by minimizing the need for manual inspections and repairs. As technology continues to advance, the capabilities of these robots are expected to expand, offering even greater benefits to the electric power industry.

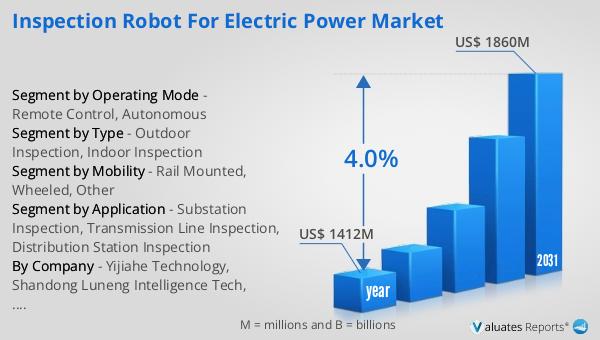

Global Inspection Robot for Electric Power Market Outlook:

In 2024, the global market for Inspection Robots in the Electric Power sector was valued at approximately $1,412 million. This market is anticipated to grow steadily, reaching an estimated value of $1,860 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.0% over the forecast period. The increasing demand for reliable and efficient power delivery systems is a significant driver of this market expansion. As the global population continues to grow and urbanize, the need for electricity is rising, necessitating the modernization and maintenance of existing power infrastructure. Inspection robots offer a solution by providing accurate and timely data on the condition of power lines, substations, and other critical components. This data-driven approach enables predictive maintenance, reducing downtime and preventing potential failures. Additionally, the integration of advanced technologies such as artificial intelligence and machine learning enhances the capabilities of these robots, allowing them to operate in challenging environments and provide real-time insights. As a result, the adoption of inspection robots is expected to increase, driving market growth. The focus on improving safety standards and reducing operational costs further contributes to the market's positive outlook. With ongoing advancements in robotics and automation, the Global Inspection Robot for Electric Power Market is poised for significant growth in the coming years.

| Report Metric | Details |

| Report Name | Inspection Robot for Electric Power Market |

| Accounted market size in year | US$ 1412 million |

| Forecasted market size in 2031 | US$ 1860 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Mobility |

|

| Segment by Operating Mode |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Yijiahe Technology, Shandong Luneng Intelligence Tech, Hangzhou Shenhao Tech, Zhejiang Guozi Robotics, Shenzhen Langchixinchuang, Dali Technology, Wanxunkeji, Energy Robotics, ANYbotics, Advantech, Power Line Robotics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |