What is Global Industrial Electric Furnace for Metallurgy Market?

The Global Industrial Electric Furnace for Metallurgy Market is a specialized segment within the broader industrial equipment sector, focusing on the production and sale of electric furnaces used in metallurgical processes. These furnaces are essential for heating and melting metals, allowing for the extraction, refining, and alloying of various metals. The market encompasses a range of furnace types, including electric arc furnaces, induction furnaces, and others, each serving specific applications and industries. The demand for these furnaces is driven by the growing need for efficient and environmentally friendly metal processing solutions. As industries worldwide strive to reduce their carbon footprint and improve energy efficiency, electric furnaces offer a viable alternative to traditional fossil fuel-based furnaces. The market is characterized by technological advancements, with manufacturers continuously innovating to enhance furnace performance, reduce energy consumption, and improve operational safety. Additionally, the market is influenced by global economic trends, industrialization in emerging economies, and regulatory policies aimed at promoting sustainable industrial practices. As a result, the Global Industrial Electric Furnace for Metallurgy Market is poised for steady growth, driven by the increasing adoption of electric furnaces across various metallurgical applications.

Electric Arc Furnace, Induction Furnace, Others in the Global Industrial Electric Furnace for Metallurgy Market:

Electric arc furnaces (EAFs) are a pivotal component of the Global Industrial Electric Furnace for Metallurgy Market. These furnaces are primarily used for steelmaking and are known for their efficiency and flexibility. EAFs operate by using electrical energy to generate heat through an electric arc, which melts the metal. This process is highly efficient and allows for precise control over the temperature and composition of the metal being processed. EAFs are particularly popular in the steel industry due to their ability to recycle scrap metal, making them an environmentally friendly option. The demand for EAFs is driven by the growing emphasis on sustainable practices and the need for high-quality steel products. Induction furnaces, on the other hand, use electromagnetic induction to heat and melt metals. These furnaces are known for their rapid heating capabilities and are widely used in the production of non-ferrous metals such as aluminum and copper. Induction furnaces offer several advantages, including energy efficiency, precise temperature control, and reduced emissions. They are ideal for applications that require high-quality metal products with minimal impurities. The market for induction furnaces is expanding as industries seek to improve their production processes and reduce their environmental impact. Other types of electric furnaces in the market include resistance furnaces and plasma furnaces. Resistance furnaces use electrical resistance to generate heat and are commonly used for heat treatment processes. Plasma furnaces, on the other hand, use plasma arcs to achieve extremely high temperatures, making them suitable for specialized applications such as the production of high-purity metals and alloys. The diversity of electric furnace types in the market reflects the wide range of metallurgical processes and applications they serve. As industries continue to evolve and adopt new technologies, the demand for electric furnaces is expected to grow, driven by the need for efficient, sustainable, and high-quality metal processing solutions.

Ferrous Metallurgy, Non-Ferrous Metallurgy in the Global Industrial Electric Furnace for Metallurgy Market:

The Global Industrial Electric Furnace for Metallurgy Market plays a crucial role in both ferrous and non-ferrous metallurgy. In ferrous metallurgy, electric furnaces are primarily used for the production and processing of iron and steel. Electric arc furnaces (EAFs) are the most common type of furnace used in this sector, offering a sustainable and efficient method for recycling scrap metal into high-quality steel products. The use of EAFs in ferrous metallurgy is driven by the growing demand for steel in various industries, including construction, automotive, and manufacturing. EAFs provide several advantages, such as reduced energy consumption, lower emissions, and the ability to produce steel with precise chemical compositions. These benefits make EAFs an attractive option for steel producers looking to improve their environmental footprint and meet stringent regulatory requirements. In non-ferrous metallurgy, electric furnaces are used for the production and processing of metals such as aluminum, copper, and zinc. Induction furnaces are particularly popular in this sector due to their ability to rapidly heat and melt non-ferrous metals with minimal energy consumption. The use of induction furnaces in non-ferrous metallurgy is driven by the increasing demand for lightweight and corrosion-resistant metals in industries such as aerospace, electronics, and transportation. Induction furnaces offer several advantages, including precise temperature control, reduced emissions, and the ability to produce high-quality metal products with minimal impurities. The growing emphasis on sustainability and energy efficiency in non-ferrous metallurgy is expected to drive the demand for electric furnaces in this sector. Overall, the Global Industrial Electric Furnace for Metallurgy Market is integral to the production and processing of both ferrous and non-ferrous metals, providing industries with efficient, sustainable, and high-quality metal processing solutions.

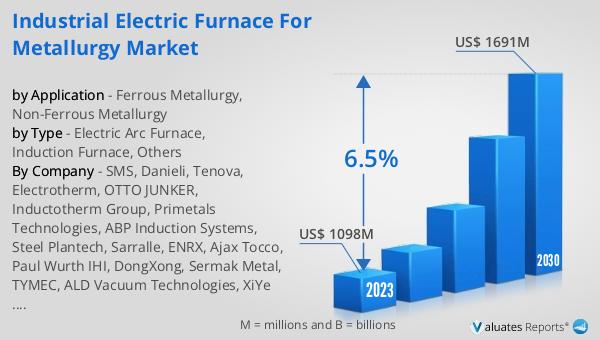

Global Industrial Electric Furnace for Metallurgy Market Outlook:

The outlook for the Global Industrial Electric Furnace for Metallurgy Market is promising, with projections indicating significant growth in the coming years. The market is expected to expand from $1,159 million in 2024 to $1,790 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.5% from 2025 to 2031. This growth is driven by the increasing demand for electric furnaces across various industries and applications. Key product segments, such as electric arc furnaces and induction furnaces, are expected to play a crucial role in this growth, as industries seek efficient and sustainable metal processing solutions. The diverse end-use applications of electric furnaces, ranging from steel production to non-ferrous metal processing, further contribute to the market's expansion. However, evolving U.S. tariff policies introduce trade cost volatility and supply chain uncertainty, posing challenges to market growth. These policies can impact the cost of raw materials and finished products, affecting the competitiveness of electric furnace manufacturers. Despite these challenges, the market is poised for growth, driven by technological advancements, increasing industrialization in emerging economies, and the growing emphasis on sustainability and energy efficiency. As industries continue to adopt electric furnaces for their metallurgical processes, the Global Industrial Electric Furnace for Metallurgy Market is expected to witness steady growth, offering opportunities for manufacturers and stakeholders in the industry.

| Report Metric | Details |

| Report Name | Industrial Electric Furnace for Metallurgy Market |

| Accounted market size in 2024 | US$ 1159 million |

| Forecasted market size in 2031 | US$ 1790 million |

| CAGR | 6.5% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | SMS, Danieli, Tenova, Electrotherm, OTTO JUNKER, Inductotherm Group, Primetals Technologies, ABP Induction Systems, Steel Plantech, Sarralle, ENRX, Ajax Tocco, Paul Wurth IHI, DongXong, Sermak Metal, TYMEC, ALD Vacuum Technologies, XiYe Technology Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |