What is Global High-Pressure Boil-Off Gas Compressor Market?

The Global High-Pressure Boil-Off Gas Compressor Market is a specialized segment within the broader industrial gas compressor industry. These compressors are specifically designed to handle boil-off gas, which is the vaporized form of liquefied natural gas (LNG) that occurs during storage and transportation. As LNG is stored at extremely low temperatures, any heat ingress can cause a portion of the liquid to vaporize, creating boil-off gas. High-pressure boil-off gas compressors are essential in capturing and re-liquefying this gas, preventing its loss and maintaining the efficiency of LNG operations. These compressors are crucial in ensuring that the LNG remains in its liquid state, minimizing wastage and optimizing the storage and transportation processes. The market for these compressors is driven by the increasing demand for LNG as a cleaner energy source, coupled with the need for efficient storage and transportation solutions. As the global energy landscape shifts towards more sustainable options, the role of high-pressure boil-off gas compressors becomes increasingly significant, supporting the infrastructure required for LNG distribution and utilization. The market is characterized by technological advancements aimed at improving compressor efficiency, reliability, and environmental compliance.

Reciprocating Compressors, Centrifugal Compressors in the Global High-Pressure Boil-Off Gas Compressor Market:

Reciprocating compressors and centrifugal compressors are two primary types of compressors used in the Global High-Pressure Boil-Off Gas Compressor Market, each with distinct characteristics and applications. Reciprocating compressors operate using a piston-driven mechanism, where pistons move back and forth within cylinders to compress the gas. This type of compressor is known for its high-pressure capabilities and is often used in applications requiring precise control over gas flow and pressure. Reciprocating compressors are particularly suited for handling smaller volumes of gas at high pressures, making them ideal for specific LNG applications where precision and reliability are paramount. They are also favored for their ability to handle varying gas compositions and pressures, providing flexibility in operations. On the other hand, centrifugal compressors utilize a rotating impeller to impart kinetic energy to the gas, converting it into pressure energy. These compressors are known for their ability to handle large volumes of gas at lower pressures, making them suitable for applications where high flow rates are required. Centrifugal compressors are often used in large-scale LNG facilities where the efficient handling of significant gas volumes is necessary. They are valued for their continuous operation capabilities and lower maintenance requirements compared to reciprocating compressors. In the context of the Global High-Pressure Boil-Off Gas Compressor Market, both reciprocating and centrifugal compressors play crucial roles, with their selection depending on specific operational needs and the scale of the LNG infrastructure. Technological advancements in both types of compressors are focused on enhancing efficiency, reducing energy consumption, and minimizing environmental impact. Manufacturers are investing in research and development to improve compressor designs, materials, and control systems, ensuring that they meet the evolving demands of the LNG industry. As the market continues to grow, the interplay between reciprocating and centrifugal compressors will remain a key factor in determining the efficiency and effectiveness of LNG storage and transportation solutions. The choice between these two types of compressors often hinges on factors such as the required pressure levels, gas composition, and the overall scale of the operation. In summary, reciprocating and centrifugal compressors each offer unique advantages and are integral to the Global High-Pressure Boil-Off Gas Compressor Market, supporting the efficient and sustainable management of LNG resources.

LNG Storage and Transport, Industrial Gas Generation in the Global High-Pressure Boil-Off Gas Compressor Market:

The Global High-Pressure Boil-Off Gas Compressor Market finds significant applications in areas such as LNG storage and transport, as well as industrial gas generation. In the context of LNG storage and transport, these compressors play a vital role in managing boil-off gas, which is a natural byproduct of storing LNG at cryogenic temperatures. As LNG is stored in tanks, any heat ingress can cause a portion of the liquid to vaporize, resulting in boil-off gas. High-pressure boil-off gas compressors are employed to capture this gas, compress it, and either re-liquefy it or use it as fuel for ship propulsion or power generation. This process not only prevents the loss of valuable gas but also enhances the efficiency and safety of LNG storage and transportation operations. By maintaining the LNG in its liquid state, these compressors help in optimizing the storage capacity and reducing the environmental impact associated with gas venting. In industrial gas generation, high-pressure boil-off gas compressors are used to manage and utilize boil-off gas as a feedstock for various industrial processes. The captured gas can be compressed and used in applications such as chemical synthesis, power generation, and as a fuel source for industrial equipment. This not only provides a sustainable solution for managing boil-off gas but also contributes to the overall efficiency and cost-effectiveness of industrial operations. The ability to capture and utilize boil-off gas as a valuable resource aligns with the growing emphasis on sustainability and resource optimization in industrial sectors. Furthermore, the use of high-pressure boil-off gas compressors in these applications supports the transition towards cleaner energy sources, as LNG is considered a more environmentally friendly alternative to traditional fossil fuels. By enabling the efficient management and utilization of LNG resources, these compressors contribute to reducing greenhouse gas emissions and promoting energy security. As the demand for LNG continues to rise, driven by the global shift towards cleaner energy solutions, the role of high-pressure boil-off gas compressors in LNG storage and transport, as well as industrial gas generation, becomes increasingly important. These compressors not only enhance the operational efficiency of LNG infrastructure but also support the broader goals of sustainability and environmental stewardship in the energy sector.

Global High-Pressure Boil-Off Gas Compressor Market Outlook:

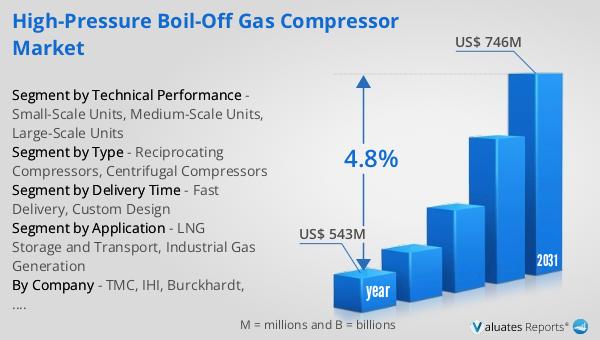

The global market for High-Pressure Boil-Off Gas Compressors was valued at approximately $543 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $746 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 4.8% over the forecast period. The increasing demand for LNG as a cleaner energy source is a primary driver of this market expansion. As countries and industries worldwide seek to reduce their carbon footprint and transition towards more sustainable energy solutions, the role of LNG becomes increasingly prominent. High-pressure boil-off gas compressors are essential in supporting this transition by ensuring the efficient storage and transportation of LNG. These compressors help in capturing and re-liquefying boil-off gas, minimizing wastage, and optimizing the overall efficiency of LNG operations. The projected growth in the market size underscores the importance of these compressors in the global energy landscape. As technological advancements continue to enhance the efficiency and reliability of high-pressure boil-off gas compressors, their adoption is expected to increase across various sectors. This growth is also indicative of the broader trends in the energy industry, where there is a strong emphasis on sustainability, efficiency, and environmental responsibility. The market outlook for high-pressure boil-off gas compressors highlights the critical role these devices play in supporting the infrastructure required for LNG distribution and utilization, ultimately contributing to a more sustainable and efficient energy future.

| Report Metric | Details |

| Report Name | High-Pressure Boil-Off Gas Compressor Market |

| Accounted market size in year | US$ 543 million |

| Forecasted market size in 2031 | US$ 746 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Technical Performance |

|

| Segment by Delivery Time |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TMC, IHI, Burckhardt, SIAD Macchine Impianti, Atlas Copco, Wärtsilä, MITSUI E&S, Ebara Elliott Energy, Hanwha Group, Siemens Energy, GEA, KOBESTEEL, Sinopec, China National Offshore Oil |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |