What is Global Fiberglass Composite Pipes Market?

The Global Fiberglass Composite Pipes Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries worldwide. Fiberglass composite pipes are made from a combination of glass fibers and resin, offering a unique blend of strength, durability, and corrosion resistance. These pipes are increasingly favored over traditional materials like steel and concrete due to their lightweight nature and ease of installation. The market for fiberglass composite pipes is driven by their extensive use in industries such as oil and gas, municipal water systems, agricultural irrigation, and industrial applications. The demand for these pipes is further fueled by the need for efficient and sustainable infrastructure solutions. As industries continue to seek materials that offer longevity and reduced maintenance costs, fiberglass composite pipes are becoming an integral part of modern engineering projects. The market is characterized by continuous innovation, with manufacturers focusing on enhancing the performance and versatility of these pipes to meet the diverse needs of end-users. Overall, the Global Fiberglass Composite Pipes Market is poised for significant growth, driven by technological advancements and the increasing emphasis on sustainable development.

Polyester, Epoxy, Others in the Global Fiberglass Composite Pipes Market:

Fiberglass composite pipes are primarily categorized based on the type of resin used in their construction, with polyester, epoxy, and other resins being the most common. Polyester resin is widely used in the production of fiberglass composite pipes due to its cost-effectiveness and satisfactory performance in various applications. It offers good mechanical properties and chemical resistance, making it suitable for use in environments where exposure to corrosive substances is a concern. Polyester-based fiberglass pipes are often used in water distribution systems, sewage treatment plants, and other municipal applications. Epoxy resin, on the other hand, is known for its superior strength and resistance to high temperatures and harsh chemicals. This makes epoxy-based fiberglass pipes ideal for demanding applications in the oil and gas industry, where they are used for transporting hydrocarbons and other aggressive fluids. The high-performance characteristics of epoxy resin also make it a preferred choice for industrial applications that require reliable and durable piping solutions. In addition to polyester and epoxy, other resins such as vinyl ester and phenolic are also used in the production of fiberglass composite pipes. Vinyl ester resin offers excellent corrosion resistance and is often used in environments where exposure to acids and alkalis is common. Phenolic resin, known for its fire-resistant properties, is used in applications where fire safety is a critical concern. The choice of resin in fiberglass composite pipes is determined by the specific requirements of the application, including factors such as temperature, pressure, and chemical exposure. Manufacturers continue to innovate and develop new resin formulations to enhance the performance and versatility of fiberglass composite pipes. This ongoing research and development effort is aimed at expanding the range of applications for these pipes and meeting the evolving needs of industries worldwide. As the demand for efficient and sustainable infrastructure solutions grows, the use of fiberglass composite pipes is expected to increase across various sectors. The versatility and adaptability of these pipes make them an attractive option for engineers and project managers seeking reliable and cost-effective piping solutions. Overall, the Global Fiberglass Composite Pipes Market is characterized by a diverse range of products that cater to the specific needs of different industries, with polyester, epoxy, and other resins playing a key role in shaping the market landscape.

Oil and Gas, Municipal, Agricultural Irrigation, Industrial, Others in the Global Fiberglass Composite Pipes Market:

The Global Fiberglass Composite Pipes Market finds extensive usage across a variety of sectors, each benefiting from the unique properties of these pipes. In the oil and gas industry, fiberglass composite pipes are used for transporting crude oil, natural gas, and other hydrocarbons. Their corrosion resistance and ability to withstand high pressures and temperatures make them ideal for use in harsh environments, such as offshore drilling platforms and refineries. The lightweight nature of fiberglass pipes also facilitates easier handling and installation, reducing labor costs and project timelines. In municipal applications, fiberglass composite pipes are used in water distribution systems, sewage treatment plants, and stormwater management. Their durability and resistance to chemical corrosion make them suitable for long-term use in municipal infrastructure projects. These pipes help ensure the efficient and reliable delivery of clean water and the safe disposal of wastewater, contributing to improved public health and environmental sustainability. In the agricultural sector, fiberglass composite pipes are used for irrigation systems, providing a reliable and efficient means of delivering water to crops. Their resistance to corrosion and ability to withstand varying environmental conditions make them suitable for use in diverse agricultural settings. The use of fiberglass pipes in irrigation systems helps optimize water usage and improve crop yields, supporting sustainable agricultural practices. In industrial applications, fiberglass composite pipes are used for transporting chemicals, acids, and other aggressive fluids. Their chemical resistance and ability to withstand high temperatures make them ideal for use in chemical processing plants, power generation facilities, and other industrial settings. The use of fiberglass pipes in industrial applications helps ensure the safe and efficient transport of hazardous materials, reducing the risk of leaks and environmental contamination. Beyond these sectors, fiberglass composite pipes are also used in a variety of other applications, including marine, mining, and construction. Their versatility and adaptability make them suitable for use in a wide range of environments and conditions. As industries continue to seek materials that offer longevity, reliability, and reduced maintenance costs, the demand for fiberglass composite pipes is expected to grow. The Global Fiberglass Composite Pipes Market is characterized by a diverse range of applications, each benefiting from the unique properties of these pipes. The ongoing development of new resin formulations and manufacturing techniques is expected to further expand the range of applications for fiberglass composite pipes, driving growth in the market. Overall, the use of fiberglass composite pipes in various sectors highlights their importance as a key component of modern infrastructure solutions.

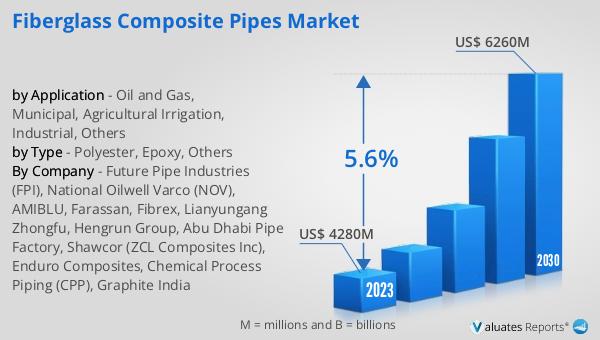

Global Fiberglass Composite Pipes Market Outlook:

The outlook for the Global Fiberglass Composite Pipes Market indicates a promising growth trajectory, with the market expected to expand from $4,514 million in 2024 to $6,575 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.6% from 2025 to 2031. This growth is driven by the increasing demand for fiberglass composite pipes across critical product segments and diverse end-use applications. Industries such as oil and gas, municipal, agricultural irrigation, and industrial sectors are increasingly adopting these pipes due to their superior properties, including corrosion resistance, durability, and ease of installation. However, the market is not without its challenges. Evolving U.S. tariff policies are introducing trade cost volatility and supply chain uncertainty, which could impact the market dynamics. These policies may lead to fluctuations in raw material prices and affect the overall cost structure of fiberglass composite pipes. Despite these challenges, the market is expected to continue its upward trajectory, driven by technological advancements and the growing emphasis on sustainable infrastructure solutions. Manufacturers are focusing on enhancing the performance and versatility of fiberglass composite pipes to meet the evolving needs of end-users. As industries continue to seek materials that offer longevity and reduced maintenance costs, the demand for fiberglass composite pipes is expected to grow, contributing to the overall expansion of the market. The Global Fiberglass Composite Pipes Market is poised for significant growth, driven by a combination of factors, including technological advancements, increasing demand from various sectors, and the need for sustainable infrastructure solutions.

| Report Metric | Details |

| Report Name | Fiberglass Composite Pipes Market |

| Accounted market size in 2024 | US$ 4514 million |

| Forecasted market size in 2031 | US$ 6575 million |

| CAGR | 5.6% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Future Pipe Industries (FPI), National Oilwell Varco (NOV), AMIBLU, Farassan, Fibrex, Lianyungang Zhongfu, Hengrun Group, Abu Dhabi Pipe Factory, Shawcor (ZCL Composites Inc), Enduro Composites, Chemical Process Piping (CPP), Graphite India |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |