What is Global Enclosed Pipe Conveyor Belt Market?

The Global Enclosed Pipe Conveyor Belt Market is a specialized segment within the broader conveyor belt industry, focusing on systems designed to transport materials in a fully enclosed manner. This market is driven by the need for efficient, environmentally friendly, and safe material handling solutions across various industries. Enclosed pipe conveyor belts are unique because they form a closed loop, which helps in minimizing spillage, reducing dust emissions, and protecting the material from external contaminants. These systems are particularly beneficial in industries where the transported materials are sensitive to environmental conditions or where contamination could lead to significant losses. The market is witnessing growth due to increasing industrialization, urbanization, and the need for sustainable practices in material handling. As industries strive to meet regulatory standards and reduce their environmental footprint, the demand for enclosed pipe conveyor belts is expected to rise. These systems are not only efficient but also offer a cost-effective solution for long-distance and complex material transport needs. The market is characterized by technological advancements, with manufacturers focusing on developing more durable, energy-efficient, and versatile conveyor systems to cater to the diverse needs of industries worldwide.

Conventional Fabric (EP/NN), Steel-Cord Reinforced, Others in the Global Enclosed Pipe Conveyor Belt Market:

The Global Enclosed Pipe Conveyor Belt Market is segmented based on the type of reinforcement used in the belts, which includes Conventional Fabric (EP/NN), Steel-Cord Reinforced, and others. Each type has its unique characteristics and applications, catering to different industrial needs. Conventional Fabric belts, often referred to as EP (polyester/nylon) or NN (nylon/nylon) belts, are known for their flexibility, lightweight nature, and cost-effectiveness. These belts are typically used in applications where the material load is moderate, and the conveyor system does not require high tensile strength. They are suitable for short to medium-length conveying distances and are often used in industries like agriculture, food processing, and light manufacturing. The flexibility of fabric belts allows them to navigate complex conveyor routes with ease, making them a popular choice for in-plant conveying systems. On the other hand, Steel-Cord Reinforced belts are designed for heavy-duty applications where high tensile strength and durability are paramount. These belts are constructed with steel cords embedded within the rubber, providing exceptional strength and resistance to wear and tear. Steel-cord belts are ideal for long-distance and high-capacity conveying needs, such as in mining, cement, and power generation industries. They can handle large volumes of material over extended distances without compromising on performance. The robust nature of steel-cord belts also makes them suitable for harsh environmental conditions, where conventional fabric belts might fail. Additionally, these belts offer excellent resistance to impact and abrasion, ensuring a longer lifespan and reduced maintenance costs. Apart from Conventional Fabric and Steel-Cord Reinforced belts, the market also includes other types of conveyor belts designed for specific applications. These may include belts made from specialized materials or with unique construction techniques to meet particular industrial requirements. For instance, some belts are designed to withstand extreme temperatures, making them suitable for industries like steel manufacturing or chemical processing. Others may be engineered to resist chemical corrosion, ensuring longevity in environments where exposure to harsh chemicals is common. The diversity in belt types allows industries to select the most appropriate solution for their specific material handling needs, ensuring efficiency and reliability in their operations. The choice between Conventional Fabric, Steel-Cord Reinforced, and other types of conveyor belts depends on several factors, including the nature of the material being transported, the distance and complexity of the conveyor route, and the environmental conditions of the operation site. Industries must carefully evaluate these factors to select the most suitable conveyor belt type, ensuring optimal performance and cost-effectiveness. As the Global Enclosed Pipe Conveyor Belt Market continues to evolve, manufacturers are investing in research and development to enhance the capabilities of these belts, focusing on improving their strength, flexibility, and resistance to various environmental factors. This ongoing innovation is expected to drive the market forward, offering industries more advanced and efficient solutions for their material handling needs.

Overland/Long-Distance Bulk Transport, In-Plant Conveying, Port / Terminal and Stockyard Conveying, Others in the Global Enclosed Pipe Conveyor Belt Market:

The Global Enclosed Pipe Conveyor Belt Market finds its application in various areas, including Overland/Long-Distance Bulk Transport, In-Plant Conveying, Port/Terminal and Stockyard Conveying, among others. Each of these applications leverages the unique advantages of enclosed pipe conveyor belts to enhance efficiency, safety, and environmental sustainability in material handling processes. Overland/Long-Distance Bulk Transport is one of the primary applications of enclosed pipe conveyor belts. These systems are designed to transport large volumes of materials over extended distances, often across challenging terrains. The enclosed design of the belts ensures that the material is protected from external elements, reducing the risk of contamination and spillage. This is particularly important in industries like mining and cement, where the transported materials are often valuable and sensitive to environmental conditions. The ability to transport materials over long distances without the need for multiple transfer points also reduces operational costs and minimizes the risk of material loss. In-Plant Conveying is another significant application area for enclosed pipe conveyor belts. Within industrial facilities, these systems are used to transport materials between different processing stages, ensuring a seamless flow of operations. The enclosed design helps maintain a clean and safe working environment by preventing dust emissions and material spillage. This is especially crucial in industries like food processing and pharmaceuticals, where hygiene and safety standards are stringent. The flexibility of enclosed pipe conveyor belts allows them to navigate complex plant layouts, making them an ideal choice for in-plant conveying needs. Port/Terminal and Stockyard Conveying is another critical application area for enclosed pipe conveyor belts. In ports and terminals, these systems are used to transport bulk materials like coal, grain, and minerals from ships to storage areas or vice versa. The enclosed design of the belts ensures that the materials are protected from weather conditions, reducing the risk of spoilage and loss. Additionally, the enclosed system minimizes dust emissions, which is essential for maintaining air quality in port areas. In stockyards, enclosed pipe conveyor belts are used to transport materials between storage areas and processing facilities, ensuring efficient and safe material handling. Apart from these primary application areas, enclosed pipe conveyor belts are also used in various other industries and applications. For instance, they are employed in power generation facilities to transport coal and other fuels to boilers. In the agricultural sector, these systems are used to transport grains and other agricultural products between storage and processing facilities. The versatility and efficiency of enclosed pipe conveyor belts make them a valuable asset in any industry that requires reliable and safe material handling solutions. As industries continue to prioritize sustainability and efficiency, the demand for enclosed pipe conveyor belts is expected to grow, driving innovation and development in this market segment.

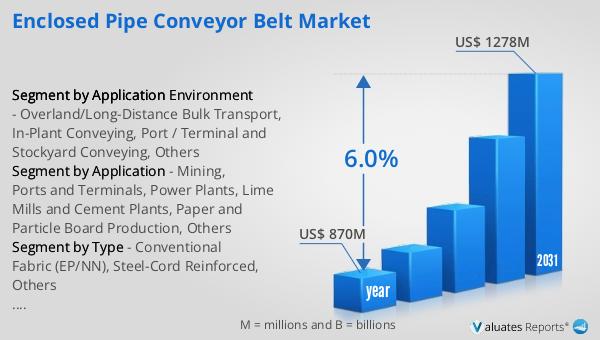

Global Enclosed Pipe Conveyor Belt Market Outlook:

In 2024, the global market for Enclosed Pipe Conveyor Belts was valued at approximately $870 million. Looking ahead, this market is anticipated to expand significantly, reaching an estimated size of $1,278 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.0% over the forecast period. The increasing demand for efficient and environmentally friendly material handling solutions across various industries is a key driver of this market growth. As industries continue to prioritize sustainability and operational efficiency, the adoption of enclosed pipe conveyor belts is expected to rise. These systems offer numerous advantages, including reduced material spillage, minimized dust emissions, and protection of materials from external contaminants. Additionally, the ability to transport materials over long distances without the need for multiple transfer points further enhances their appeal. The market is also benefiting from technological advancements, with manufacturers focusing on developing more durable, energy-efficient, and versatile conveyor systems. As a result, the Global Enclosed Pipe Conveyor Belt Market is poised for significant growth, offering industries advanced solutions for their material handling needs.

| Report Metric | Details |

| Report Name | Enclosed Pipe Conveyor Belt Market |

| Accounted market size in year | US$ 870 million |

| Forecasted market size in 2031 | US$ 1278 million |

| CAGR | 6.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Pipe Diameter |

|

| Segment by Application Environment |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | ContiTech, Bando Chemical Industries, Metso, Forech, Pro Conveyor Belt(PCB), DoubleArrow, Baoding Huayue Rubber Belts Co., Ltd, DRB Industrial |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |