What is Global VFFS Vertical Form Fill Seal Food Packaging Machine Market?

The Global VFFS (Vertical Form Fill Seal) Food Packaging Machine Market is a specialized segment within the packaging machinery industry, focusing on machines that are designed to package food products efficiently and effectively. These machines operate by forming a vertical bag from a flat roll of film, filling it with the product, and then sealing it to create a packaged product. This process is highly automated and is used extensively in the food industry due to its speed and efficiency. The VFFS machines are versatile and can handle a wide range of food products, from dry goods to liquids, making them an essential tool for food manufacturers looking to optimize their packaging processes. The market for these machines is driven by the increasing demand for packaged food products, advancements in packaging technology, and the need for efficient and cost-effective packaging solutions. As consumer preferences shift towards convenience and sustainability, the VFFS market continues to evolve, offering innovative solutions that meet the changing needs of the food industry.

Intermittent, Continuous in the Global VFFS Vertical Form Fill Seal Food Packaging Machine Market:

In the realm of the Global VFFS Vertical Form Fill Seal Food Packaging Machine Market, two primary operational modes are prevalent: intermittent and continuous. Intermittent VFFS machines operate in a start-stop manner, where the film stops momentarily for the filling and sealing process. This method is particularly advantageous for packaging products that require precise placement or handling, such as fragile items or those with irregular shapes. The intermittent process allows for greater control over the packaging operation, ensuring that each package is filled and sealed accurately. This mode is often favored by manufacturers who prioritize precision and quality over speed. On the other hand, continuous VFFS machines maintain a constant motion, with the film moving continuously through the machine as it is filled and sealed. This method is ideal for high-speed production environments where efficiency and throughput are paramount. Continuous machines are designed to handle large volumes of product with minimal downtime, making them suitable for industries where speed is critical. The choice between intermittent and continuous VFFS machines depends largely on the specific needs of the manufacturer, including the type of product being packaged, the desired production speed, and the level of precision required. Both types of machines offer unique advantages and can be customized to meet the diverse demands of the food packaging industry. As technology advances, the distinction between intermittent and continuous machines becomes less pronounced, with many modern VFFS machines offering hybrid capabilities that combine the benefits of both modes. This flexibility allows manufacturers to adapt to changing market conditions and consumer preferences, ensuring that they remain competitive in a dynamic industry. The Global VFFS Vertical Form Fill Seal Food Packaging Machine Market continues to grow as manufacturers seek innovative solutions that enhance efficiency, reduce costs, and improve the overall quality of their packaged products.

Dry Foods, Snacks and Confectionery, Frozen Foods, Ready-To-Eat Meals and Convenience Foods, Fresh Produce and Salad Components, Others in the Global VFFS Vertical Form Fill Seal Food Packaging Machine Market:

The Global VFFS Vertical Form Fill Seal Food Packaging Machine Market plays a crucial role in various sectors of the food industry, offering tailored solutions for different types of products. In the dry foods category, VFFS machines are used extensively to package items such as rice, pasta, and cereals. These machines ensure that the products are sealed in airtight packages, preserving their freshness and extending their shelf life. The ability to handle a wide range of bag sizes and shapes makes VFFS machines ideal for dry food packaging, where versatility and efficiency are key. In the snacks and confectionery sector, VFFS machines are employed to package products like chips, candies, and chocolates. The machines' ability to handle delicate items without damaging them is a significant advantage, ensuring that the final product reaches consumers in perfect condition. For frozen foods, VFFS machines provide a reliable solution for packaging items such as vegetables, fruits, and ready-to-cook meals. The machines' capability to operate in low-temperature environments ensures that the integrity of the frozen products is maintained throughout the packaging process. In the realm of ready-to-eat meals and convenience foods, VFFS machines offer a fast and efficient way to package a variety of products, from soups and sauces to complete meal kits. The machines' flexibility allows manufacturers to switch between different packaging formats quickly, catering to the diverse needs of consumers seeking convenient meal options. Fresh produce and salad components also benefit from the use of VFFS machines, which help maintain the freshness and quality of the products by providing airtight seals that prevent contamination and spoilage. Additionally, VFFS machines are used in other areas of the food industry, such as packaging spices, condiments, and pet food, demonstrating their versatility and adaptability to different packaging requirements. The Global VFFS Vertical Form Fill Seal Food Packaging Machine Market continues to expand as manufacturers seek innovative solutions that enhance the efficiency and quality of their packaging processes, meeting the evolving demands of consumers worldwide.

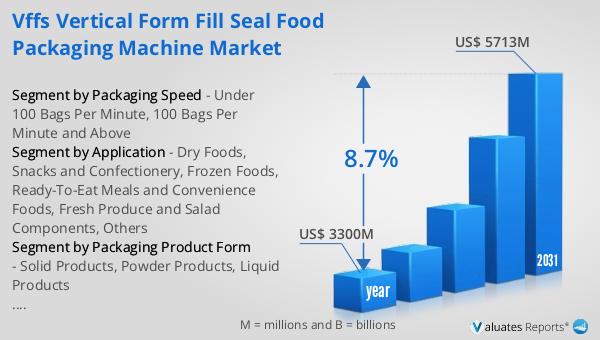

Global VFFS Vertical Form Fill Seal Food Packaging Machine Market Outlook:

The outlook for the Global VFFS Vertical Form Fill Seal Food Packaging Machine Market indicates a promising future, with significant growth expected over the coming years. In 2024, the market was valued at approximately US$ 3,300 million, reflecting the strong demand for efficient and versatile packaging solutions in the food industry. This demand is driven by several factors, including the increasing consumption of packaged food products, advancements in packaging technology, and the need for cost-effective and sustainable packaging solutions. As the market continues to evolve, it is projected to reach a revised size of US$ 5,713 million by 2031, growing at a compound annual growth rate (CAGR) of 8.7% during the forecast period. This growth is indicative of the ongoing innovation and development within the VFFS market, as manufacturers strive to meet the changing needs of consumers and the food industry. The increasing focus on convenience, sustainability, and product quality is driving the adoption of VFFS machines, as they offer a reliable and efficient solution for packaging a wide range of food products. As the market expands, manufacturers are likely to continue investing in research and development to enhance the capabilities of VFFS machines, ensuring that they remain at the forefront of the packaging industry.

| Report Metric | Details |

| Report Name | VFFS Vertical Form Fill Seal Food Packaging Machine Market |

| Accounted market size in year | US$ 3300 million |

| Forecasted market size in 2031 | US$ 5713 million |

| CAGR | 8.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Packaging Product Form |

|

| Segment by Packaging Speed |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MF TECNO, CAM Packaging Systems Inc, Syntegon, Fres-co, Viking Masek, ROVEMA, Tokyo Automatic Machinery, Nichrome Packaging Solutions, Sealed Air, Triangle Package Machinery Company, Barry-Wehmiller Companies, Vtops, Guangzhou Yundu Machinery Technology Co., Ltd, Foshan Samfull Packing Machine Co.,Ltd, Elinpack, KITECH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |