What is Global Electric Gripper for Collaborative Robots Market?

The Global Electric Gripper for Collaborative Robots Market is a rapidly evolving sector within the robotics industry, focusing on the development and deployment of electric grippers designed specifically for collaborative robots, or cobots. These grippers are essential components that enable robots to handle objects with precision and care, making them suitable for a variety of applications across different industries. Unlike traditional robotic grippers, electric grippers are powered by electricity, allowing for more precise control and adaptability. This market is driven by the increasing demand for automation and efficiency in manufacturing processes, as well as the growing adoption of collaborative robots in various sectors. The electric grippers are designed to be versatile and easy to integrate with existing robotic systems, which makes them an attractive option for businesses looking to enhance their production capabilities. As industries continue to seek ways to improve productivity and reduce operational costs, the demand for electric grippers for collaborative robots is expected to grow, offering significant opportunities for innovation and development in this field.

2-Finger Electric Gripper, 3-Finger Electric Gripper in the Global Electric Gripper for Collaborative Robots Market:

The 2-Finger Electric Gripper and 3-Finger Electric Gripper are two prominent types of grippers within the Global Electric Gripper for Collaborative Robots Market. The 2-Finger Electric Gripper is widely used due to its simplicity and efficiency in handling a variety of objects. It is designed to mimic the human hand's pinching motion, making it ideal for tasks that require precision and dexterity. This type of gripper is commonly used in applications where objects need to be picked up, moved, or assembled with care. Its design allows for easy integration with collaborative robots, making it a popular choice for industries such as electronics, where delicate components need to be handled with precision. The 2-Finger Electric Gripper is also favored for its ability to adapt to different object sizes and shapes, providing flexibility in various manufacturing processes. On the other hand, the 3-Finger Electric Gripper offers enhanced versatility and functionality. With an additional finger, this gripper can handle more complex tasks that require a firmer grip or the ability to manipulate objects in a more sophisticated manner. The 3-Finger Electric Gripper is particularly useful in applications where objects are irregularly shaped or require a more secure hold. This makes it suitable for industries such as automotive and aerospace, where components can vary significantly in size and shape. The additional finger allows for a more stable grip, reducing the risk of dropping or damaging objects during handling. Both types of grippers are designed to be energy-efficient and easy to program, allowing for seamless integration with collaborative robots. They are equipped with sensors and advanced control systems that enable them to adjust their grip based on the object's characteristics, ensuring safe and efficient operation. As the demand for automation continues to rise, the development of more advanced and capable electric grippers is expected to drive further growth in the Global Electric Gripper for Collaborative Robots Market. These grippers play a crucial role in enhancing the capabilities of collaborative robots, enabling them to perform a wider range of tasks with greater precision and efficiency. As industries continue to embrace automation, the need for versatile and reliable electric grippers will only increase, paving the way for continued innovation and development in this field.

Automotive, Electronics, Food and Beverage, Pharmaceutical, Others in the Global Electric Gripper for Collaborative Robots Market:

The Global Electric Gripper for Collaborative Robots Market finds extensive usage across various industries, including automotive, electronics, food and beverage, pharmaceutical, and others. In the automotive industry, electric grippers are used to handle components such as gears, pistons, and other parts that require precise assembly. The ability of electric grippers to adapt to different sizes and shapes makes them ideal for assembling complex automotive components, ensuring high levels of accuracy and efficiency. In the electronics industry, electric grippers are essential for handling delicate components such as circuit boards, chips, and other sensitive parts. The precision and control offered by electric grippers allow for careful handling of these components, reducing the risk of damage and ensuring high-quality assembly. In the food and beverage industry, electric grippers are used for tasks such as packaging, sorting, and handling of food products. The ability to handle a wide range of products with varying shapes and sizes makes electric grippers an invaluable tool in this industry. They are designed to meet strict hygiene standards, ensuring that food products are handled safely and efficiently. In the pharmaceutical industry, electric grippers are used for tasks such as filling, packaging, and handling of pharmaceutical products. The precision and control offered by electric grippers ensure that products are handled with care, reducing the risk of contamination and ensuring high-quality production. In addition to these industries, electric grippers are also used in other sectors such as logistics, where they are used for tasks such as sorting and handling of packages. The versatility and adaptability of electric grippers make them suitable for a wide range of applications, driving their adoption across various industries. As the demand for automation continues to grow, the usage of electric grippers in collaborative robots is expected to increase, offering significant opportunities for growth and development in this market.

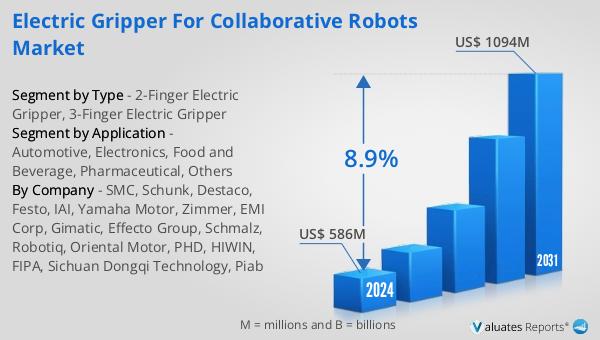

Global Electric Gripper for Collaborative Robots Market Outlook:

The outlook for the Global Electric Gripper for Collaborative Robots Market is promising, with projections indicating significant growth in the coming years. The market is expected to expand from $586 million in 2024 to $1,094 million by 2031, reflecting a compound annual growth rate (CAGR) of 8.9% from 2025 to 2031. This growth is driven by the increasing demand for automation and the adoption of collaborative robots across various industries. The versatility and adaptability of electric grippers make them an attractive option for businesses looking to enhance their production capabilities and improve efficiency. However, evolving U.S. tariff policies introduce trade-cost volatility and supply-chain uncertainty, which could impact the market's growth trajectory. Despite these challenges, the market is expected to continue its upward trend, driven by critical product segments and diverse end-use applications. As industries continue to seek ways to improve productivity and reduce operational costs, the demand for electric grippers for collaborative robots is expected to grow, offering significant opportunities for innovation and development in this field. The market's growth is also supported by advancements in technology, which are expected to lead to the development of more advanced and capable electric grippers, further enhancing the capabilities of collaborative robots.

| Report Metric | Details |

| Report Name | Electric Gripper for Collaborative Robots Market |

| Accounted market size in 2024 | US$ 586 million |

| Forecasted market size in 2031 | US$ 1094 million |

| CAGR | 8.9% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | SMC, Schunk, Destaco, Festo, IAI, Yamaha Motor, Zimmer, EMI Corp, Gimatic, Effecto Group, Schmalz, Robotiq, Oriental Motor, PHD, HIWIN, FIPA, Sichuan Dongqi Technology, Piab |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |