What is Global Desktop Mask Alignment Lithography Machine Market?

The Global Desktop Mask Alignment Lithography Machine Market refers to the industry focused on the production and distribution of specialized equipment used in the photolithography process, a crucial step in semiconductor manufacturing. These machines are designed to align and transfer intricate patterns onto semiconductor wafers, which are essential components in electronic devices. The market is driven by the increasing demand for smaller, more efficient electronic devices, which require precise and accurate patterning capabilities. Desktop mask alignment lithography machines are particularly valued for their compact size, making them suitable for smaller production environments or research labs where space is limited. They offer a cost-effective solution for prototyping and small-scale production, allowing manufacturers to experiment with new designs and technologies without the need for large-scale industrial equipment. As technology continues to advance, the need for high-precision lithography machines is expected to grow, further fueling the market's expansion. The market encompasses a range of products, from basic models for educational purposes to advanced systems capable of handling complex manufacturing processes. This diversity allows the market to cater to a wide array of industries, including microelectronics, biotechnology, and materials science.

Contact Exposure, Non-contact Exposure in the Global Desktop Mask Alignment Lithography Machine Market:

Contact exposure and non-contact exposure are two fundamental techniques used in the Global Desktop Mask Alignment Lithography Machine Market, each with its unique applications and advantages. Contact exposure involves placing the photomask in direct contact with the photoresist-coated substrate. This method is known for its simplicity and cost-effectiveness, making it a popular choice for applications where high precision is not the primary concern. The direct contact ensures that the pattern is accurately transferred, but it also poses a risk of damaging the photomask or substrate due to physical contact. This method is often used in educational settings or for prototyping, where the cost of equipment and materials is a significant consideration. On the other hand, non-contact exposure, also known as proximity or projection lithography, involves projecting the pattern onto the substrate without direct contact. This technique is preferred for high-precision applications, as it minimizes the risk of damage and allows for more intricate patterning. Non-contact exposure is ideal for producing smaller feature sizes, which are increasingly in demand in the microelectronics industry. The choice between contact and non-contact exposure depends on several factors, including the desired resolution, production volume, and budget. In high-volume manufacturing environments, non-contact exposure is often favored due to its ability to produce consistent results with minimal wear and tear on the equipment. However, for small-scale production or research purposes, contact exposure may be more suitable due to its lower cost and ease of use. Both methods play a crucial role in the lithography process, and advancements in technology continue to enhance their capabilities. As the demand for smaller, more efficient electronic devices grows, the need for precise and reliable lithography techniques will only increase, driving further innovation in the Global Desktop Mask Alignment Lithography Machine Market.

Microelectronics Manufacturing, IC Production, Scientific Research, Teaching in the Global Desktop Mask Alignment Lithography Machine Market:

The Global Desktop Mask Alignment Lithography Machine Market finds extensive usage across various fields, including microelectronics manufacturing, integrated circuit (IC) production, scientific research, and teaching. In microelectronics manufacturing, these machines are essential for creating the intricate patterns required for semiconductor devices. The ability to produce small, precise features is crucial as electronic devices become more compact and powerful. Desktop mask alignment lithography machines offer a cost-effective solution for manufacturers looking to prototype new designs or produce small batches of products. In IC production, these machines are used to transfer circuit patterns onto silicon wafers, a critical step in the fabrication process. The precision and accuracy offered by desktop lithography machines ensure that the circuits function correctly, which is vital for the performance of the final product. In scientific research, these machines are used to explore new materials and technologies. Researchers can experiment with different patterns and materials to develop innovative solutions for various applications, from sensors to biochips. The compact size and versatility of desktop lithography machines make them ideal for research labs where space and resources may be limited. In educational settings, these machines serve as valuable teaching tools, allowing students to gain hands-on experience with the photolithography process. By working with desktop mask alignment lithography machines, students can better understand the complexities of semiconductor manufacturing and prepare for careers in the industry. Overall, the Global Desktop Mask Alignment Lithography Machine Market plays a vital role in advancing technology and education, supporting innovation across multiple sectors.

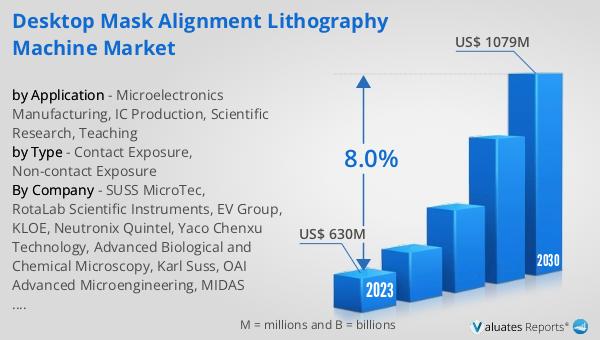

Global Desktop Mask Alignment Lithography Machine Market Outlook:

The global Desktop Mask Alignment Lithography Machine market is anticipated to expand significantly, with projections indicating growth from US$ 680 million in 2024 to US$ 1157 million by 2031, reflecting a compound annual growth rate (CAGR) of 8.0% from 2025 to 2031. This growth is driven by the critical importance of product segments and the diverse range of end-use applications that these machines support. As industries continue to evolve and demand more sophisticated electronic devices, the need for precise and efficient lithography solutions becomes increasingly apparent. However, the market is not without its challenges. Evolving U.S. tariff policies introduce a level of volatility in trade costs and create uncertainty within the supply chain. These factors can impact the availability and pricing of raw materials and components, potentially affecting production timelines and costs. Despite these challenges, the market's growth prospects remain strong, supported by ongoing technological advancements and the increasing demand for high-precision manufacturing solutions. As companies navigate these complexities, they are likely to focus on innovation and efficiency to maintain a competitive edge. The market's expansion is a testament to the critical role that desktop mask alignment lithography machines play in the broader landscape of semiconductor manufacturing and technology development.

| Report Metric | Details |

| Report Name | Desktop Mask Alignment Lithography Machine Market |

| Accounted market size in 2024 | US$ 680 million |

| Forecasted market size in 2031 | US$ 1157 million |

| CAGR | 8.0% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | SUSS MicroTec, RotaLab Scientific Instruments, EV Group, KLOE, Neutronix Quintel, Yaco Chenxu Technology, Advanced Biological and Chemical Microscopy, Karl Suss, OAI Advanced Microengineering, MIDAS Systems, MJB, NIL Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |