What is Global Biogas Membrane Market?

The Global Biogas Membrane Market is a rapidly evolving sector that focuses on the use of membrane technology to enhance the production and purification of biogas. Biogas, a renewable energy source, is produced through the anaerobic digestion of organic materials such as agricultural waste, municipal waste, and industrial by-products. Membrane technology plays a crucial role in this process by separating and purifying the biogas, ensuring that it meets the required standards for use as a clean energy source. The market for biogas membranes is driven by the increasing demand for sustainable energy solutions and the need to reduce greenhouse gas emissions. As countries worldwide strive to meet their renewable energy targets, the adoption of biogas membrane technology is expected to grow. This market encompasses various types of membranes, including microfiltration, ultrafiltration, and others, each offering unique benefits in terms of efficiency and cost-effectiveness. The global biogas membrane market is characterized by continuous innovation and technological advancements, making it a dynamic and promising field for investment and development.

Microfiltration (MF), Ultrafiltration (UF) in the Global Biogas Membrane Market:

Microfiltration (MF) and Ultrafiltration (UF) are two critical technologies within the Global Biogas Membrane Market, each playing a significant role in the purification and enhancement of biogas production. Microfiltration involves the use of membranes with pore sizes ranging from 0.1 to 10 micrometers. This technology is primarily used to remove suspended solids, bacteria, and other large particles from the biogas. The process is relatively low-pressure, making it energy-efficient and cost-effective. Microfiltration is often employed as a pre-treatment step in biogas purification, ensuring that larger contaminants are removed before further processing. On the other hand, Ultrafiltration uses membranes with smaller pore sizes, typically between 0.01 to 0.1 micrometers. This technology is effective in removing smaller particles, including viruses and colloids, from the biogas. Ultrafiltration operates at a higher pressure compared to microfiltration, but it provides a higher level of purification, making it suitable for applications where high-quality biogas is required. Both MF and UF technologies are integral to the biogas membrane market, offering solutions that cater to different purification needs. The choice between microfiltration and ultrafiltration depends on various factors, including the quality of the raw biogas, the desired purity level, and the specific application requirements. In agricultural settings, for instance, microfiltration might be sufficient to remove large particles from biogas produced from animal waste. However, in industrial applications where biogas is used as a feedstock for chemical production, ultrafiltration may be necessary to achieve the required purity levels. The integration of MF and UF technologies in biogas production systems enhances the overall efficiency and sustainability of the process. By effectively removing impurities, these technologies help in reducing the environmental impact of biogas production and ensure compliance with regulatory standards. Moreover, the use of advanced membrane materials and designs in MF and UF systems contributes to their durability and performance, making them a viable long-term solution for biogas purification. As the demand for clean and renewable energy sources continues to rise, the role of microfiltration and ultrafiltration in the biogas membrane market is expected to grow. These technologies not only improve the quality of biogas but also support the broader goals of energy sustainability and environmental protection. The ongoing research and development in membrane technology are likely to yield further improvements in the efficiency and cost-effectiveness of MF and UF systems, driving their adoption across various sectors. In conclusion, microfiltration and ultrafiltration are essential components of the Global Biogas Membrane Market, offering versatile and effective solutions for biogas purification. Their ability to remove a wide range of contaminants makes them suitable for diverse applications, from agriculture to industry, contributing to the growth and sustainability of the biogas sector.

Agricultural, Municipal, Industrial in the Global Biogas Membrane Market:

The Global Biogas Membrane Market finds extensive applications across various sectors, including agriculture, municipal, and industrial areas, each benefiting from the unique advantages of membrane technology. In the agricultural sector, biogas membranes are used to process waste from livestock and crop residues, converting them into valuable biogas. This not only provides a renewable energy source for farms but also helps in managing waste effectively, reducing odors, and minimizing the environmental impact of agricultural activities. The use of biogas membranes in agriculture supports sustainable farming practices by promoting the recycling of organic waste and reducing reliance on fossil fuels. In municipal applications, biogas membranes are employed in wastewater treatment plants to capture and purify biogas generated from the anaerobic digestion of sewage sludge. This process not only helps in reducing the volume of waste but also produces a clean energy source that can be used to power the treatment facilities or be fed into the local energy grid. The integration of biogas membrane technology in municipal waste management systems contributes to the reduction of greenhouse gas emissions and supports the transition to a circular economy. In the industrial sector, biogas membranes are used to treat organic waste generated from various manufacturing processes, including food and beverage production, chemical manufacturing, and pharmaceuticals. By converting industrial waste into biogas, companies can reduce their environmental footprint and lower energy costs. The purified biogas can be used as a renewable energy source within the industrial facility or sold to external markets, providing an additional revenue stream. The adoption of biogas membrane technology in industrial applications aligns with the growing emphasis on corporate sustainability and environmental responsibility. Overall, the use of biogas membranes in agricultural, municipal, and industrial sectors highlights the versatility and effectiveness of this technology in promoting sustainable energy solutions. By facilitating the conversion of organic waste into clean energy, biogas membranes play a crucial role in addressing environmental challenges and supporting the global transition to renewable energy sources. As the demand for sustainable waste management and energy solutions continues to rise, the Global Biogas Membrane Market is poised for significant growth, driven by its applications across these key sectors.

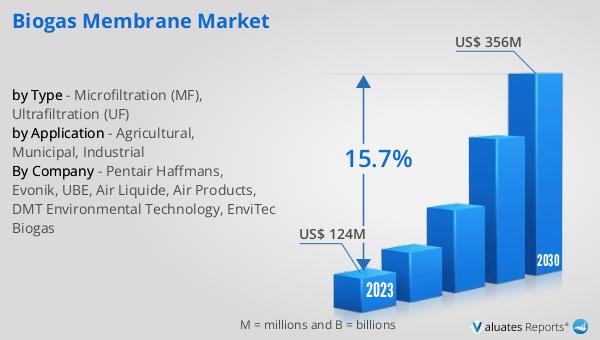

Global Biogas Membrane Market Outlook:

The outlook for the Global Biogas Membrane Market indicates a promising growth trajectory, with projections suggesting an increase from $148 million in 2024 to $406 million by 2031. This growth, at a compound annual growth rate (CAGR) of 15.7% between 2025 and 2031, is fueled by the expansion of critical product segments and the diversification of end-use applications. The increasing demand for renewable energy sources and the need for efficient waste management solutions are key drivers of this market. Biogas membranes offer a sustainable solution by converting organic waste into clean energy, making them an attractive option for various sectors, including agriculture, municipal, and industrial applications. However, the market also faces challenges, particularly in the form of evolving U.S. tariff policies, which introduce trade-cost volatility and supply-chain uncertainty. These factors could impact the cost and availability of biogas membrane technology, affecting its adoption across different regions. Despite these challenges, the Global Biogas Membrane Market is expected to continue its upward trajectory, driven by technological advancements and the growing emphasis on sustainability and environmental responsibility. As countries worldwide strive to meet their renewable energy targets, the demand for biogas membrane technology is likely to increase, supporting the market's growth in the coming years.

| Report Metric | Details |

| Report Name | Biogas Membrane Market |

| Accounted market size in 2024 | US$ 148 million |

| Forecasted market size in 2031 | US$ 406 million |

| CAGR | 15.7% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Pentair Haffmans, Evonik, UBE, Air Liquide, Air Products, DMT Environmental Technology, EnviTec Biogas |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |