What is Global Bio-based Polyolefins Market?

The Global Bio-based Polyolefins Market represents a significant shift towards sustainable materials in the polymer industry. Polyolefins, which include polyethylene and polypropylene, are traditionally derived from fossil fuels. However, the bio-based variants are produced using renewable resources such as sugarcane, corn, and other biomass. This transition is driven by the increasing demand for environmentally friendly products and the need to reduce carbon footprints. Bio-based polyolefins offer similar properties to their conventional counterparts, such as durability, flexibility, and resistance to chemicals, making them suitable for various applications. The market is witnessing growth due to rising awareness about sustainability and stringent regulations on carbon emissions. Companies are investing in research and development to enhance the performance and cost-effectiveness of bio-based polyolefins, further propelling market expansion. As industries continue to prioritize eco-friendly solutions, the Global Bio-based Polyolefins Market is poised for substantial growth, offering a viable alternative to traditional plastics. This market not only supports environmental goals but also opens up new opportunities for innovation in material science.

in the Global Bio-based Polyolefins Market:

The Global Bio-based Polyolefins Market is characterized by a variety of types that cater to diverse customer needs. One of the primary types is bio-based polyethylene, which is derived from renewable resources like sugarcane. This type is popular due to its versatility and is used in applications ranging from packaging to automotive components. Bio-based polyethylene offers the same properties as conventional polyethylene, such as flexibility, strength, and chemical resistance, making it a preferred choice for manufacturers looking to reduce their environmental impact. Another significant type is bio-based polypropylene, which is also derived from renewable sources. It is known for its high melting point, making it suitable for applications that require heat resistance, such as automotive parts and industrial components. Bio-based polypropylene is gaining traction due to its ability to reduce greenhouse gas emissions compared to its fossil-based counterpart. Additionally, there are bio-based polyolefin elastomers, which are used in applications requiring elasticity and flexibility, such as in the production of films and coatings. These elastomers are derived from renewable resources and offer similar performance characteristics to traditional elastomers, making them an attractive option for industries aiming to enhance sustainability. The market also includes bio-based polyolefin copolymers, which are used in specialized applications that require a combination of properties from different types of polyolefins. These copolymers are engineered to meet specific performance requirements, offering manufacturers the ability to tailor materials to their needs. The diversity of types within the Global Bio-based Polyolefins Market reflects the growing demand for sustainable materials across various industries. As companies continue to seek eco-friendly alternatives, the development and adoption of different types of bio-based polyolefins are expected to increase, driving innovation and growth in the market. This trend underscores the importance of sustainability in material selection and highlights the potential for bio-based polyolefins to replace traditional plastics in numerous applications.

Flexible Packaging, Rigid Packaging, Consumer Products, Automotive, Industrial, Agriculture, Others in the Global Bio-based Polyolefins Market:

The usage of Global Bio-based Polyolefins Market spans several key areas, each benefiting from the unique properties of these sustainable materials. In flexible packaging, bio-based polyolefins are used to create films and wraps that are both durable and environmentally friendly. These materials offer excellent barrier properties, protecting products from moisture and contaminants while reducing the carbon footprint associated with traditional packaging materials. In rigid packaging, bio-based polyolefins are used to manufacture containers and bottles that are lightweight yet strong. These materials provide the necessary structural integrity for packaging applications while supporting sustainability goals. In the consumer products sector, bio-based polyolefins are used in the production of items such as toys, household goods, and personal care products. Their versatility and safety make them ideal for products that come into direct contact with consumers. In the automotive industry, bio-based polyolefins are used in the production of interior and exterior components, offering a lightweight alternative to traditional materials. This not only enhances fuel efficiency but also reduces the environmental impact of vehicle manufacturing. In industrial applications, bio-based polyolefins are used in the production of pipes, fittings, and other components that require durability and chemical resistance. These materials offer a sustainable solution for industries looking to reduce their reliance on fossil fuels. In agriculture, bio-based polyolefins are used in the production of films and nets that protect crops and enhance yield. These materials offer a biodegradable alternative to conventional agricultural plastics, supporting sustainable farming practices. The diverse applications of bio-based polyolefins highlight their potential to replace traditional plastics across various industries, driving the shift towards a more sustainable future.

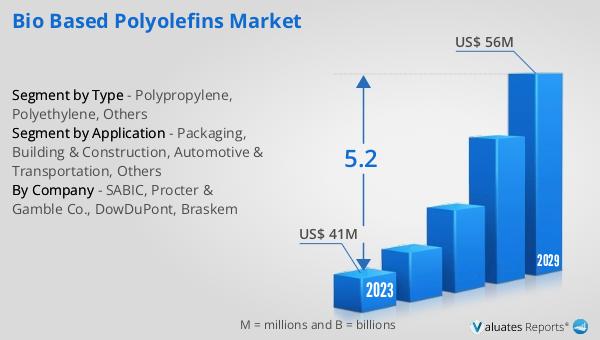

Global Bio-based Polyolefins Market Outlook:

The global market for bio-based polyolefins is on a promising trajectory, reflecting the growing emphasis on sustainable materials. In 2024, the market was valued at approximately US$ 334 million, indicating a strong foundation for growth. By 2031, it is projected to reach an impressive size of US$ 663 million, driven by a compound annual growth rate (CAGR) of 10.9% during the forecast period. This substantial growth underscores the increasing demand for eco-friendly alternatives to traditional plastics. The market's expansion is fueled by several factors, including heightened awareness of environmental issues, regulatory pressures to reduce carbon emissions, and technological advancements in bio-based material production. Companies are increasingly investing in research and development to enhance the performance and cost-effectiveness of bio-based polyolefins, making them more competitive with conventional plastics. As industries across the globe prioritize sustainability, the demand for bio-based polyolefins is expected to rise, offering a viable solution to the environmental challenges posed by traditional plastics. This market outlook highlights the potential for bio-based polyolefins to play a significant role in the transition towards a more sustainable and circular economy.

| Report Metric | Details |

| Report Name | Bio-based Polyolefins Market |

| Accounted market size in year | US$ 334 million |

| Forecasted market size in 2031 | US$ 663 million |

| CAGR | 10.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Polymer Type |

|

| Segment by Certification |

|

| Segment by Feedstock Route |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Braskem, SABIC, INEOS Olefins & Polymers, Borealis, TotalEnergies Polymers, LyondellBasell, Repsol, Versalis, Dow, Prime Polymer, Formosa Plastics USA, Westlake, LG Chem, Reliance Industries, India Glycols, Sinopec, Avient |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |