What is Global Amine-based Epoxy Hardener Market?

The Global Amine-based Epoxy Hardener Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of hardeners used in epoxy systems. These hardeners are crucial for curing epoxy resins, which are widely used in various applications due to their excellent adhesive properties, chemical resistance, and mechanical strength. The market encompasses a range of amine-based hardeners, including aliphatic amines, cycloaliphatic amines, aromatic amines, and others, each offering unique properties that cater to specific industrial needs. The demand for these hardeners is driven by their extensive use in industries such as construction, automotive, electronics, and wind energy, where they play a vital role in enhancing the performance and durability of epoxy-based products. The market is characterized by continuous innovation and development, with manufacturers focusing on creating more efficient and environmentally friendly hardeners to meet the evolving needs of end-users. As industries continue to seek high-performance materials, the Global Amine-based Epoxy Hardener Market is poised for growth, driven by technological advancements and increasing applications across various sectors.

Aliphatic Amines, Dicyandiamide, Amidoamine, Polyamide, Others in the Global Amine-based Epoxy Hardener Market:

Aliphatic amines are a key component of the Global Amine-based Epoxy Hardener Market, known for their versatility and effectiveness in curing epoxy resins. These amines are characterized by their open-chain structure, which allows for flexibility and adaptability in various applications. Aliphatic amines are particularly valued for their ability to provide excellent adhesion, chemical resistance, and mechanical strength to epoxy systems. They are commonly used in coatings, adhesives, and sealants, where their properties enhance the performance and durability of the final product. Dicyandiamide, another important hardener in this market, is a solid curing agent that offers unique benefits. It is known for its ability to provide a long pot life and high thermal stability, making it ideal for applications that require prolonged working times and exposure to high temperatures. Dicyandiamide is often used in the electronics industry, where its properties are essential for the production of printed circuit boards and other electronic components. Amidoamine hardeners are derived from the reaction of polyamines with fatty acids, resulting in a product that offers excellent flexibility and impact resistance. These hardeners are commonly used in coatings and adhesives, where their properties contribute to the durability and resilience of the final product. Polyamide hardeners, on the other hand, are known for their excellent chemical resistance and ability to cure at low temperatures. They are widely used in marine and industrial coatings, where their properties help protect surfaces from harsh environmental conditions. Other amine-based hardeners in the market include cycloaliphatic amines and aromatic amines, each offering unique benefits that cater to specific industrial needs. Cycloaliphatic amines are valued for their ability to provide high gloss and UV resistance, making them ideal for applications in the automotive and aerospace industries. Aromatic amines, meanwhile, are known for their high thermal stability and chemical resistance, making them suitable for use in high-performance coatings and adhesives. The diversity of amine-based hardeners available in the market allows manufacturers to select the most appropriate product for their specific application, ensuring optimal performance and durability. As industries continue to demand high-performance materials, the Global Amine-based Epoxy Hardener Market is expected to grow, driven by the development of new and innovative hardeners that meet the evolving needs of end-users.

Coatings, Construction, Wind Energy, Electrical & Electronics, Adhesives, Composites, Other in the Global Amine-based Epoxy Hardener Market:

The Global Amine-based Epoxy Hardener Market finds extensive usage across a variety of industries, each benefiting from the unique properties of these hardeners. In the coatings industry, amine-based epoxy hardeners are essential for producing high-performance coatings that offer excellent adhesion, chemical resistance, and durability. These coatings are used in a wide range of applications, from protective coatings for industrial equipment to decorative coatings for consumer products. In the construction industry, amine-based epoxy hardeners are used in the production of adhesives and sealants that provide strong bonds and long-lasting protection against environmental factors. These products are essential for ensuring the structural integrity and longevity of buildings and infrastructure. The wind energy sector also relies on amine-based epoxy hardeners for the production of composite materials used in wind turbine blades. These hardeners provide the necessary strength and durability to withstand the harsh environmental conditions that wind turbines are exposed to. In the electrical and electronics industry, amine-based epoxy hardeners are used in the production of printed circuit boards and other electronic components. Their excellent thermal stability and chemical resistance make them ideal for applications that require reliable performance in demanding conditions. Adhesives and composites are other key areas where amine-based epoxy hardeners are used. In the adhesives industry, these hardeners provide strong bonds and excellent resistance to environmental factors, making them suitable for a wide range of applications, from automotive assembly to consumer products. In the composites industry, amine-based epoxy hardeners are used to produce lightweight and durable materials that are used in a variety of applications, from aerospace to sports equipment. Other industries that benefit from the use of amine-based epoxy hardeners include marine, automotive, and aerospace, where their properties contribute to the performance and durability of a wide range of products. As industries continue to seek high-performance materials, the Global Amine-based Epoxy Hardener Market is expected to grow, driven by the increasing demand for innovative and efficient hardeners that meet the evolving needs of end-users.

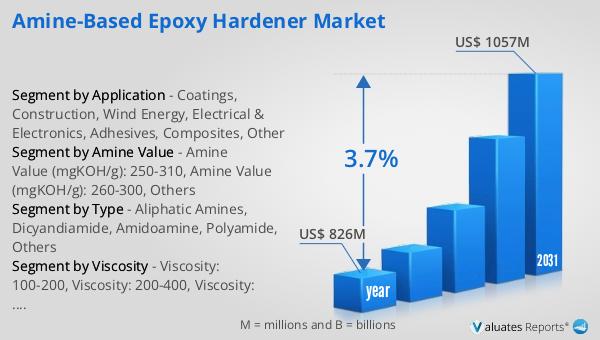

Global Amine-based Epoxy Hardener Market Outlook:

The global market for Amine-based Epoxy Hardener was valued at $826 million in 2024 and is anticipated to expand to a revised size of $1,057 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.7% over the forecast period. This growth trajectory underscores the increasing demand for amine-based epoxy hardeners across various industries, driven by their superior performance characteristics and versatility. The market's expansion is fueled by the continuous development of new and innovative hardeners that cater to the evolving needs of end-users. As industries such as construction, automotive, electronics, and wind energy continue to seek high-performance materials, the demand for amine-based epoxy hardeners is expected to rise. The market's growth is also supported by the increasing focus on sustainability and environmental responsibility, with manufacturers developing more efficient and environmentally friendly hardeners. This trend is expected to drive further innovation and development in the market, as companies strive to meet the growing demand for sustainable and high-performance materials. As a result, the Global Amine-based Epoxy Hardener Market is poised for continued growth, offering significant opportunities for manufacturers and end-users alike.

| Report Metric | Details |

| Report Name | Amine-based Epoxy Hardener Market |

| Accounted market size in year | US$ 826 million |

| Forecasted market size in 2031 | US$ 1057 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Viscosity |

|

| Segment by Amine Value |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Evonik, KUKDO, Atul, Olin, Westlake, Mitsubishi Chemical, Rich Chemical, Honrel Group, HUBEI BESTWAY TECHNOLOGY, Highfar, Feiyang Protech, Purnima Group, Aditya Birla Advanced Materials, Shenzhen Xuhua Biotechnology, WUHAN HONREPOXY |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |