What is Dicing Die Attach Film- Global Market?

Dicing Die Attach Film is a crucial component in the semiconductor manufacturing process, playing a vital role in ensuring the integrity and performance of semiconductor devices. This film is used to attach semiconductor dies to substrates or other dies, providing a stable and reliable bond that can withstand the rigors of further processing and use. The global market for Dicing Die Attach Film is driven by the increasing demand for semiconductors across various industries, including consumer electronics, automotive, and telecommunications. As technology advances, the need for smaller, more efficient, and more powerful semiconductor devices grows, which in turn fuels the demand for high-quality dicing die attach films. These films must meet stringent requirements for thermal conductivity, electrical insulation, and mechanical stability, making them a critical component in the semiconductor supply chain. The market is characterized by a high level of competition, with several key players vying for market share by offering innovative products and solutions that meet the evolving needs of semiconductor manufacturers. As the industry continues to evolve, the demand for dicing die attach films is expected to grow, driven by the ongoing advancements in semiconductor technology and the increasing complexity of semiconductor devices.

Non-Conductive Type, Conductive Type in the Dicing Die Attach Film- Global Market:

Dicing Die Attach Film comes in two main types: Non-Conductive and Conductive. Each type serves specific purposes and is chosen based on the requirements of the semiconductor device being manufactured. Non-Conductive Dicing Die Attach Film is primarily used in applications where electrical insulation is critical. This type of film provides a strong bond between the die and the substrate or another die while ensuring that there is no electrical conductivity between them. This is particularly important in devices where electrical isolation is necessary to prevent short circuits or interference between different components. Non-Conductive films are often used in consumer electronics, where the miniaturization of devices requires precise and reliable bonding solutions that do not compromise the electrical performance of the device. On the other hand, Conductive Dicing Die Attach Film is used in applications where electrical conductivity is required between the die and the substrate. This type of film is designed to provide a strong mechanical bond while also allowing for the efficient transfer of electrical signals between the components. Conductive films are often used in power devices and other applications where electrical performance is critical. The choice between Non-Conductive and Conductive Dicing Die Attach Film depends on the specific requirements of the application, including the need for electrical insulation or conductivity, thermal management, and mechanical stability. Both types of films are engineered to meet the demanding requirements of the semiconductor industry, providing reliable and efficient bonding solutions that support the performance and longevity of semiconductor devices. As the semiconductor industry continues to evolve, the demand for both Non-Conductive and Conductive Dicing Die Attach Films is expected to grow, driven by the increasing complexity and performance requirements of semiconductor devices.

Die to Substrate, Die to Die, Film on Wire in the Dicing Die Attach Film- Global Market:

Dicing Die Attach Film is used in various applications within the semiconductor manufacturing process, including Die to Substrate, Die to Die, and Film on Wire. Each application has its own unique requirements and challenges, which the film must address to ensure the reliability and performance of the final semiconductor device. In Die to Substrate applications, the film is used to attach the semiconductor die to a substrate, which serves as the foundation for the device. This application requires the film to provide a strong and stable bond that can withstand the thermal and mechanical stresses of further processing and use. The film must also provide adequate thermal management to dissipate heat generated by the die during operation, ensuring the device's performance and longevity. In Die to Die applications, the film is used to bond two semiconductor dies together, creating a multi-die package. This application requires the film to provide a reliable bond that can accommodate the different thermal expansion rates of the dies, preventing mechanical stress and potential failure. The film must also ensure electrical isolation between the dies, preventing short circuits and interference. Film on Wire applications involve using the film to attach semiconductor dies to wire bonds, which connect the die to the external circuitry. This application requires the film to provide a strong bond that can withstand the mechanical stresses of wire bonding and the thermal stresses of device operation. The film must also ensure electrical isolation between the die and the wire bonds, preventing short circuits and interference. Each of these applications requires the film to meet stringent requirements for thermal conductivity, electrical insulation, and mechanical stability, making it a critical component in the semiconductor manufacturing process. As the demand for smaller, more efficient, and more powerful semiconductor devices grows, the need for high-quality dicing die attach films that can meet these requirements is expected to increase.

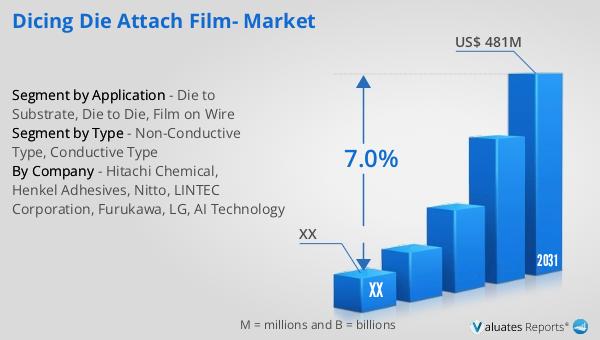

Dicing Die Attach Film- Global Market Outlook:

The global market for Dicing Die Attach Film was valued at approximately US$ 301 million in 2024, with projections indicating a growth to around US$ 481 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.0% during the forecast period from 2025 to 2031. The market is dominated by the top three manufacturers, who collectively hold about 77% of the global market share. Regionally, China Taiwan stands out as the largest market for dicing die attach films, accounting for roughly 45% of the global market. This is followed by China and North America, which represent 19% and 14% of the market, respectively. In terms of application, the Die to Die segment emerges as the largest, constituting approximately 51% of the total market. This significant share underscores the importance of dicing die attach films in multi-die packaging applications, where reliable bonding solutions are critical to the performance and longevity of semiconductor devices. As the semiconductor industry continues to evolve, driven by advancements in technology and the increasing demand for more powerful and efficient devices, the market for dicing die attach films is expected to grow, with manufacturers focusing on innovation and quality to meet the evolving needs of their customers.

| Report Metric | Details |

| Report Name | Dicing Die Attach Film- Market |

| Forecasted market size in 2031 | US$ 481 million |

| CAGR | 7.0% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hitachi Chemical, Henkel Adhesives, Nitto, LINTEC Corporation, Furukawa, LG, AI Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |