What is Global Wired Conduit Interconnect Assemblies Market?

The Global Wired Conduit Interconnect Assemblies Market refers to the industry focused on the production and distribution of wired conduit interconnect assemblies, which are essential components used to protect and route electrical wiring in various applications. These assemblies are crucial in ensuring the safe and efficient transmission of electrical signals and power across different sectors. They consist of conduits, which are tubes or channels that house and protect electrical wires, and interconnects, which are connectors that facilitate the joining of different electrical components. The market for these assemblies is driven by the increasing demand for reliable and durable electrical infrastructure in industries such as aerospace, automotive, construction, and healthcare. As technology advances and industries continue to grow, the need for sophisticated and robust wiring solutions becomes more pronounced, thereby fueling the demand for wired conduit interconnect assemblies. The market is characterized by a diverse range of products tailored to meet the specific requirements of different applications, ensuring safety, efficiency, and compliance with industry standards.

Technical-grade, Aviation-grade, Medical-grade in the Global Wired Conduit Interconnect Assemblies Market:

In the Global Wired Conduit Interconnect Assemblies Market, products are often categorized based on their grade, which determines their suitability for specific applications. Technical-grade assemblies are designed for general industrial use, where the primary focus is on durability and cost-effectiveness. These assemblies are typically used in environments where the conditions are not overly harsh, but reliability is still a key concern. They are constructed to withstand moderate levels of stress and environmental factors, making them suitable for a wide range of industrial applications. Aviation-grade assemblies, on the other hand, are engineered to meet the stringent requirements of the aerospace industry. These assemblies must adhere to rigorous safety and performance standards due to the critical nature of their applications. They are designed to withstand extreme conditions such as high altitudes, temperature fluctuations, and vibrations, ensuring the safety and reliability of aircraft systems. The materials used in aviation-grade assemblies are often lightweight yet robust, providing the necessary strength without adding excessive weight to the aircraft. Medical-grade assemblies are tailored for use in healthcare settings, where hygiene and precision are paramount. These assemblies must comply with strict regulatory standards to ensure they do not compromise patient safety. They are often used in medical devices and equipment, where reliable electrical connections are crucial for accurate diagnostics and treatment. The materials used in medical-grade assemblies are typically biocompatible and resistant to sterilization processes, ensuring they can be safely used in clinical environments. Each grade of wired conduit interconnect assembly is designed to meet the specific demands of its intended application, providing the necessary balance of performance, safety, and cost. As industries continue to evolve, the demand for specialized assemblies that can meet the unique challenges of different sectors is expected to grow, driving innovation and development within the market.

Industry Automation, Aerospace, Building Automation, Medical Device, Others in the Global Wired Conduit Interconnect Assemblies Market:

The Global Wired Conduit Interconnect Assemblies Market finds extensive application across various sectors, each with its unique requirements and challenges. In the realm of Industry Automation, these assemblies play a crucial role in ensuring the seamless operation of automated systems. They provide the necessary infrastructure for routing electrical signals and power to different components of an automated system, ensuring that machines and equipment operate efficiently and reliably. The durability and flexibility of these assemblies make them ideal for use in dynamic industrial environments where machinery is constantly in motion. In the Aerospace sector, wired conduit interconnect assemblies are indispensable for maintaining the integrity of electrical systems in aircraft. They are used to protect and route wiring throughout the aircraft, ensuring that all electrical components function correctly under the demanding conditions of flight. The assemblies must be lightweight yet robust, capable of withstanding the vibrations, temperature extremes, and pressure changes experienced during flight. In Building Automation, these assemblies are used to integrate various building systems, such as lighting, HVAC, and security, into a cohesive network. They facilitate the efficient transmission of signals and power, enabling the centralized control and monitoring of building systems for improved energy efficiency and occupant comfort. In the Medical Device sector, wired conduit interconnect assemblies are critical for ensuring the reliable operation of medical equipment. They provide the necessary connections for transmitting electrical signals and power to various components of medical devices, ensuring accurate diagnostics and treatment. The assemblies used in this sector must meet stringent regulatory standards to ensure they do not compromise patient safety. Beyond these specific sectors, wired conduit interconnect assemblies are also used in a variety of other applications, each with its unique set of requirements. Whether in telecommunications, transportation, or renewable energy, these assemblies provide the essential infrastructure for reliable and efficient electrical connections, supporting the safe and effective operation of systems across diverse industries.

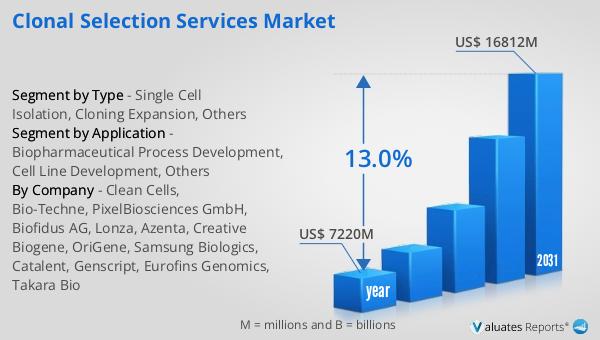

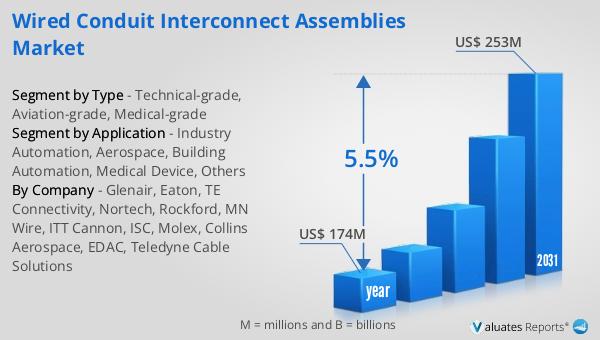

Global Wired Conduit Interconnect Assemblies Market Outlook:

The global market for Wired Conduit Interconnect Assemblies was valued at $174 million in 2024 and is anticipated to expand to a revised size of $253 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.5% over the forecast period. This growth trajectory underscores the increasing demand for these assemblies across various industries, driven by the need for reliable and efficient electrical infrastructure. As industries continue to evolve and adopt more advanced technologies, the demand for sophisticated wiring solutions that can support these advancements is expected to rise. The market's growth is also fueled by the ongoing development of new materials and technologies that enhance the performance and durability of wired conduit interconnect assemblies. These innovations are enabling manufacturers to produce assemblies that can withstand more extreme conditions and meet the specific requirements of different applications. As a result, the market is characterized by a diverse range of products, each tailored to meet the unique needs of its intended application. This diversity is a key factor driving the market's growth, as it allows manufacturers to cater to a wide range of industries and applications. The projected growth of the market reflects the increasing importance of wired conduit interconnect assemblies in supporting the safe and efficient operation of electrical systems across various sectors.

| Report Metric | Details |

| Report Name | Wired Conduit Interconnect Assemblies Market |

| Accounted market size in year | US$ 174 million |

| Forecasted market size in 2031 | US$ 253 million |

| CAGR | 5.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Glenair, Eaton, TE Connectivity, Nortech, Rockford, MN Wire, ITT Cannon, ISC, Molex, Collins Aerospace, EDAC, Teledyne Cable Solutions |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |