What is Global Roll-to-roll Die-cutting Machine Market?

The Global Roll-to-roll Die-cutting Machine Market is a specialized segment within the broader machinery industry, focusing on machines designed to cut, shape, and process materials in a continuous roll format. These machines are integral to industries that require precise and efficient cutting of materials such as paper, plastic, metal, and textiles. The roll-to-roll die-cutting process involves feeding a roll of material through a machine that uses a die to cut shapes or patterns. This method is highly efficient for mass production, as it allows for continuous operation without the need for manual intervention between cuts. The market for these machines is driven by the demand for high-speed, accurate, and cost-effective production processes in various sectors, including packaging, electronics, automotive, and textiles. As industries continue to seek ways to improve efficiency and reduce waste, the roll-to-roll die-cutting machine market is expected to grow, offering advanced technologies and automation features to meet these needs. The market is characterized by a range of machines, from fully automatic systems that require minimal human intervention to semi-automatic models that offer flexibility and control for smaller production runs.

Fully Automatic, Semi-automatic in the Global Roll-to-roll Die-cutting Machine Market:

In the Global Roll-to-roll Die-cutting Machine Market, machines are broadly categorized into fully automatic and semi-automatic systems, each offering distinct advantages and catering to different industrial needs. Fully automatic roll-to-roll die-cutting machines are designed for high-volume production environments where speed and precision are paramount. These machines are equipped with advanced automation features that allow them to operate with minimal human intervention, making them ideal for large-scale manufacturing processes. They are often integrated with computerized control systems that ensure consistent quality and reduce the likelihood of errors. The automation in these machines not only enhances productivity but also significantly reduces labor costs, as fewer operators are needed to oversee the production process. Additionally, fully automatic machines often come with features such as automatic material feeding, cutting, and stacking, which further streamline operations and increase efficiency. On the other hand, semi-automatic roll-to-roll die-cutting machines offer a balance between automation and manual control, making them suitable for smaller production runs or specialized applications where flexibility is required. These machines typically require some level of human intervention, such as loading and unloading materials or adjusting settings for different production runs. This manual involvement allows operators to have greater control over the cutting process, which can be beneficial for custom or low-volume orders. Semi-automatic machines are often favored by businesses that need to switch between different materials or designs frequently, as they offer the flexibility to make adjustments quickly and easily. While they may not match the speed and efficiency of fully automatic systems, semi-automatic machines provide a cost-effective solution for companies that do not require the high output levels of fully automated systems. The choice between fully automatic and semi-automatic roll-to-roll die-cutting machines often depends on the specific needs of a business, including production volume, budget, and the level of customization required. Fully automatic machines are typically more expensive due to their advanced features and capabilities, but they offer significant long-term savings in terms of labor costs and production efficiency. In contrast, semi-automatic machines are generally more affordable and provide greater flexibility, making them an attractive option for small to medium-sized enterprises or those with diverse production requirements. As technology continues to advance, both types of machines are becoming increasingly sophisticated, with features such as digital controls, precision cutting, and energy-efficient designs becoming standard. This evolution is helping to drive the growth of the Global Roll-to-roll Die-cutting Machine Market, as businesses across various industries seek to enhance their production capabilities and remain competitive in an ever-changing market landscape.

Labels, Packaging, Other in the Global Roll-to-roll Die-cutting Machine Market:

The Global Roll-to-roll Die-cutting Machine Market finds extensive application across various industries, with significant usage in areas such as labels, packaging, and other specialized sectors. In the labels industry, roll-to-roll die-cutting machines are essential for producing high-quality labels efficiently and cost-effectively. These machines allow for the precise cutting of labels from continuous rolls of material, ensuring uniformity and accuracy in each piece. The ability to produce large volumes of labels quickly makes these machines indispensable for industries such as food and beverage, pharmaceuticals, and consumer goods, where labeling is a critical component of product packaging and branding. The flexibility of roll-to-roll die-cutting machines also allows for the production of custom labels, catering to the diverse needs of businesses seeking to differentiate their products in a competitive market. In the packaging sector, roll-to-roll die-cutting machines play a crucial role in the production of various packaging materials, including boxes, cartons, and flexible packaging. These machines enable manufacturers to cut and shape packaging materials with precision, ensuring that each piece meets the required specifications for size, shape, and design. The efficiency of roll-to-roll die-cutting machines allows for high-speed production, reducing lead times and increasing the overall productivity of packaging operations. This is particularly important in industries such as e-commerce, where the demand for packaging materials is rapidly increasing due to the growth of online shopping. The ability to produce packaging materials quickly and accurately helps businesses meet customer demands and maintain a competitive edge in the market. Beyond labels and packaging, roll-to-roll die-cutting machines are used in a variety of other applications, including the production of electronic components, automotive parts, and textiles. In the electronics industry, these machines are used to cut and shape materials such as films, foils, and adhesives, which are essential components in the manufacturing of electronic devices. The precision and efficiency of roll-to-roll die-cutting machines make them ideal for producing intricate components that require high levels of accuracy. Similarly, in the automotive industry, these machines are used to produce gaskets, seals, and other components that require precise cutting and shaping. The versatility of roll-to-roll die-cutting machines allows them to be used in a wide range of applications, making them a valuable asset for businesses across various sectors. As industries continue to evolve and demand for high-quality, cost-effective production processes increases, the Global Roll-to-roll Die-cutting Machine Market is expected to grow, offering innovative solutions to meet the diverse needs of businesses worldwide.

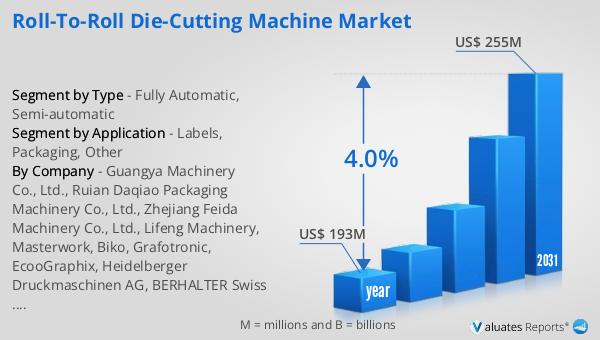

Global Roll-to-roll Die-cutting Machine Market Outlook:

The outlook for the Global Roll-to-roll Die-cutting Machine Market indicates a promising growth trajectory over the coming years. In 2024, the market was valued at approximately US$ 193 million, reflecting the significant demand for these machines across various industries. As businesses continue to seek efficient and cost-effective production solutions, the market is projected to expand, reaching an estimated size of US$ 255 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.0% during the forecast period. The increasing adoption of roll-to-roll die-cutting machines can be attributed to their ability to enhance productivity, reduce waste, and improve the overall quality of finished products. As industries such as packaging, electronics, and automotive continue to evolve, the demand for advanced die-cutting solutions is expected to rise, driving the market forward. The projected growth of the Global Roll-to-roll Die-cutting Machine Market underscores the importance of these machines in modern manufacturing processes. With their ability to handle a wide range of materials and produce high-quality outputs, roll-to-roll die-cutting machines are becoming an integral part of production lines across various sectors. The market's expansion is also supported by technological advancements, which are leading to the development of more sophisticated and efficient machines. Features such as digital controls, precision cutting, and energy-efficient designs are becoming increasingly common, offering businesses enhanced capabilities and greater flexibility in their production processes. As the market continues to grow, companies that invest in roll-to-roll die-cutting machines are likely to benefit from improved operational efficiency, reduced costs, and the ability to meet the evolving demands of their customers.

| Report Metric | Details |

| Report Name | Roll-to-roll Die-cutting Machine Market |

| Accounted market size in year | US$ 193 million |

| Forecasted market size in 2031 | US$ 255 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Guangya Machinery Co., Ltd., Ruian Daqiao Packaging Machinery Co., Ltd., Zhejiang Feida Machinery Co., Ltd., Lifeng Machinery, Masterwork, Biko, Grafotronic, EcooGraphix, Heidelberger Druckmaschinen AG, BERHALTER Swiss Die - Cutter, Teneth, BOBST, Vicut, BW Papersystems, U-Pack International Ltd, RK LABLE PRINTING MACHINERY PVT LTD, Wenzhou Mingliang Paper Plate Machinery Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |