What is Global Medical Grade PVC Granules Market?

The Global Medical Grade PVC Granules Market is a specialized segment within the broader PVC industry, focusing on the production and distribution of high-quality polyvinyl chloride (PVC) granules specifically designed for medical applications. These granules are engineered to meet stringent medical standards, ensuring they are safe for use in healthcare settings. Medical grade PVC granules are used in the manufacturing of a wide range of medical devices and consumables, such as tubing, containers, and protective equipment. The demand for these granules is driven by the healthcare sector's need for reliable, durable, and cost-effective materials that can withstand sterilization processes and maintain biocompatibility. The market is characterized by continuous innovation, as manufacturers strive to develop PVC formulations that are free from harmful additives, such as phthalates, to meet regulatory requirements and address environmental and health concerns. As the global healthcare industry expands, particularly in emerging markets, the demand for medical grade PVC granules is expected to grow, driven by the increasing need for medical devices and consumables that are both safe and effective. This market plays a crucial role in supporting the healthcare infrastructure by providing essential materials that contribute to patient safety and care quality.

Phthalates Compound, Non-phthalates Compound in the Global Medical Grade PVC Granules Market:

Phthalates and non-phthalates compounds are critical components in the Global Medical Grade PVC Granules Market, each serving distinct roles in the formulation of PVC products. Phthalates are a group of chemical compounds commonly used as plasticizers, substances added to plastics to increase their flexibility, transparency, durability, and longevity. In the context of medical grade PVC granules, phthalates have traditionally been used to enhance the performance characteristics of PVC products, making them more suitable for various medical applications. However, the use of phthalates, particularly certain types like DEHP (di(2-ethylhexyl) phthalate), has raised health and environmental concerns. Studies have suggested that phthalates can leach out of PVC products and potentially cause adverse health effects, leading to increased scrutiny and regulatory restrictions. As a result, there has been a significant shift towards developing non-phthalate alternatives in the medical grade PVC granules market. Non-phthalate compounds are designed to provide similar plasticizing effects without the associated health risks. These alternatives include bio-based plasticizers and other innovative compounds that meet the rigorous safety and performance standards required for medical applications. The transition to non-phthalate compounds is driven by regulatory pressures, consumer demand for safer products, and the healthcare industry's commitment to sustainability. Manufacturers are investing in research and development to create non-phthalate formulations that not only match the performance of traditional phthalates but also offer additional benefits, such as improved biocompatibility and reduced environmental impact. This shift is reshaping the landscape of the medical grade PVC granules market, as companies strive to balance performance, safety, and sustainability in their product offerings. The adoption of non-phthalate compounds is expected to accelerate as more countries implement stricter regulations on phthalate use in medical products. This trend is also supported by the growing awareness among healthcare providers and patients about the potential risks associated with phthalates, leading to increased demand for safer alternatives. The development of non-phthalate medical grade PVC granules represents a significant advancement in the industry, offering a viable solution to the challenges posed by traditional phthalates while ensuring the continued availability of high-quality materials for medical applications. As the market evolves, the focus on non-phthalate compounds is likely to drive innovation and growth, providing new opportunities for manufacturers and contributing to the overall improvement of healthcare products and practices.

Hemodialysis Consumables, Infusion and Injection Consumable, Urology Consumables, Gloves and Protective Equipment, Medical Device Housings and Components, Others in the Global Medical Grade PVC Granules Market:

The Global Medical Grade PVC Granules Market finds extensive application across various medical fields, each with specific requirements and standards. In the area of hemodialysis consumables, medical grade PVC granules are used to manufacture components such as blood tubing sets and dialyzer membranes. These products require materials that can withstand repeated sterilization and maintain biocompatibility to ensure patient safety during dialysis procedures. The flexibility and durability of PVC make it an ideal choice for these applications, providing reliable performance in critical healthcare settings. In infusion and injection consumables, PVC granules are used to produce items like IV bags, tubing, and connectors. These products must meet stringent safety standards to prevent contamination and ensure the safe delivery of medications and fluids to patients. Medical grade PVC granules offer the necessary properties, such as chemical resistance and clarity, to support these applications, making them a preferred material in the production of infusion and injection consumables. Urology consumables, including catheters and drainage bags, also rely on medical grade PVC granules for their construction. The material's flexibility and biocompatibility are essential for patient comfort and safety, as these products are often used for extended periods. PVC's ability to be easily molded and sterilized further enhances its suitability for urology applications. In the realm of gloves and protective equipment, medical grade PVC granules are used to produce disposable gloves that provide a barrier against contaminants and pathogens. These gloves are essential for maintaining hygiene and safety in healthcare environments, and PVC's durability and cost-effectiveness make it a popular choice for this application. Additionally, medical device housings and components, such as enclosures for electronic medical equipment, benefit from the use of PVC granules. The material's strength, chemical resistance, and ease of processing allow for the production of durable and reliable components that protect sensitive medical devices. Beyond these specific applications, medical grade PVC granules are also used in various other medical products, including respiratory masks, surgical drapes, and wound care products. The versatility of PVC, combined with its ability to meet the rigorous standards of the healthcare industry, ensures its continued use across a wide range of medical applications. As the demand for high-quality medical devices and consumables grows, the role of medical grade PVC granules in supporting healthcare infrastructure and improving patient outcomes remains critical.

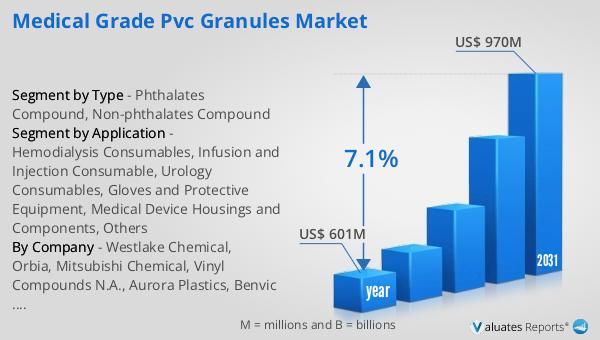

Global Medical Grade PVC Granules Market Outlook:

The global market for Medical Grade PVC Granules was valued at approximately $601 million in 2024, reflecting its significant role in the healthcare industry. This market is projected to expand substantially, reaching an estimated size of $970 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 7.1% over the forecast period. The increasing demand for medical grade PVC granules is driven by several factors, including the rising need for medical devices and consumables, advancements in PVC formulations, and the healthcare sector's focus on safety and sustainability. As healthcare systems worldwide continue to evolve and expand, particularly in emerging markets, the demand for reliable and cost-effective materials like medical grade PVC granules is expected to rise. This growth is further supported by the ongoing shift towards non-phthalate compounds, which address health and environmental concerns associated with traditional phthalates. The market's expansion is indicative of the critical role that medical grade PVC granules play in supporting healthcare infrastructure and improving patient care. As manufacturers continue to innovate and develop new formulations, the market is poised for continued growth, offering opportunities for companies to meet the evolving needs of the healthcare industry.

| Report Metric | Details |

| Report Name | Medical Grade PVC Granules Market |

| Accounted market size in year | US$ 601 million |

| Forecasted market size in 2031 | US$ 970 million |

| CAGR | 7.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Westlake Chemical, Orbia, Mitsubishi Chemical, Vinyl Compounds N.A., Aurora Plastics, Benvic Group, INEOS Compounds, Teknor Apex, Flex Technologies, Empol (IFFCO), GEON Performance Solutions, Konnark Polymer, Mazda Plastic, Thevinyl, RIKEN, SCG Chemicalss, Color Master, Manner Polymers, Intek Plastics, Hanwha, Kingfa Sci.& Tech., Guangdong Silver Age Sci & Tech, Tatsuta Chemical, NAN YA PLASTICS, ZEON KASEI |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |