What is Global Fatigue Tester for Automotive Market?

The Global Fatigue Tester for Automotive Market is an essential segment within the automotive industry, focusing on the evaluation of materials and components under cyclic loading conditions to predict their lifespan and durability. This market is driven by the increasing demand for reliable and durable vehicles, as manufacturers strive to enhance the performance and safety of their products. Fatigue testers are crucial in simulating real-world conditions, allowing engineers to identify potential weaknesses in materials and components before they are used in production. These testers are used to assess various automotive parts, including suspension systems, chassis, and engine components, ensuring they can withstand the stresses and strains of everyday use. The market is characterized by continuous advancements in testing technologies, with manufacturers investing in research and development to improve the accuracy and efficiency of fatigue testing equipment. As the automotive industry evolves, the demand for advanced fatigue testing solutions is expected to grow, driven by the need for lightweight materials and the increasing complexity of vehicle designs. This market plays a vital role in ensuring the safety and reliability of vehicles, ultimately contributing to consumer confidence and satisfaction.

Low Frequency, Medium Frequency, High Frequency in the Global Fatigue Tester for Automotive Market:

In the Global Fatigue Tester for Automotive Market, frequency-based testing is a critical aspect that determines how materials and components respond to different stress levels over time. Low-frequency fatigue testing involves applying cyclic loads at a slower rate, typically below 10 Hz. This type of testing is essential for evaluating components that experience prolonged stress over extended periods, such as structural parts of a vehicle. Low-frequency tests help in understanding how materials behave under conditions that mimic real-world usage, where components are subjected to continuous stress over long durations. This testing is crucial for ensuring the durability and longevity of automotive parts, as it helps identify potential failure points that could compromise vehicle safety. Medium-frequency fatigue testing, on the other hand, operates at a frequency range between 10 Hz and 100 Hz. This testing is particularly useful for components that experience moderate levels of stress and strain during their operational life. Medium-frequency tests are often used for parts that undergo regular but not constant stress, such as certain engine components and suspension systems. By simulating these conditions, manufacturers can gain insights into the performance and reliability of materials under typical driving scenarios. This type of testing helps in optimizing the design and material selection for automotive components, ensuring they can withstand the demands of everyday use without compromising performance. High-frequency fatigue testing is conducted at frequencies above 100 Hz and is used to evaluate components that experience rapid and repetitive stress cycles. This type of testing is crucial for parts that are subjected to high-speed operations, such as those found in high-performance vehicles or racing cars. High-frequency tests help in understanding how materials and components behave under extreme conditions, where rapid stress cycles can lead to fatigue failure. By conducting high-frequency tests, manufacturers can ensure that their products meet the rigorous demands of high-speed applications, providing enhanced performance and safety for end-users. Each frequency range in fatigue testing serves a specific purpose, addressing different aspects of material and component behavior under cyclic loading. Low-frequency tests focus on long-term durability, medium-frequency tests address typical operational conditions, and high-frequency tests evaluate performance under extreme conditions. Together, these testing methodologies provide a comprehensive understanding of how automotive components will perform throughout their lifecycle, enabling manufacturers to design and produce vehicles that are both safe and reliable. As the automotive industry continues to innovate, the role of frequency-based fatigue testing will remain crucial in ensuring the quality and performance of vehicles on the road.

Passenger Vehicle, Commercial Vehicle in the Global Fatigue Tester for Automotive Market:

The Global Fatigue Tester for Automotive Market plays a significant role in the development and testing of both passenger and commercial vehicles. In the passenger vehicle segment, fatigue testers are used extensively to ensure the safety and reliability of various components. Passenger vehicles are designed for comfort and convenience, but they must also meet stringent safety standards. Fatigue testing helps manufacturers evaluate the durability of critical components such as suspension systems, chassis, and engine parts. By simulating real-world driving conditions, fatigue testers can identify potential weaknesses in materials and designs, allowing manufacturers to make necessary improvements before vehicles reach the market. This process is vital for maintaining consumer trust and satisfaction, as it ensures that passenger vehicles are safe and reliable for everyday use. In the commercial vehicle segment, fatigue testing is equally important, if not more so. Commercial vehicles, such as trucks and buses, are subjected to more demanding conditions than passenger vehicles. They often carry heavy loads and operate for extended periods, making durability and reliability crucial factors. Fatigue testers are used to evaluate the performance of components under these challenging conditions, ensuring that commercial vehicles can withstand the rigors of daily operations. This testing is essential for preventing breakdowns and ensuring the safety of both drivers and cargo. By identifying potential failure points in advance, manufacturers can design more robust and reliable commercial vehicles, reducing maintenance costs and downtime for fleet operators. The use of fatigue testers in both passenger and commercial vehicle segments highlights the importance of this market in the automotive industry. As vehicles become more complex and consumer expectations continue to rise, the demand for advanced fatigue testing solutions will grow. Manufacturers must invest in cutting-edge testing technologies to stay competitive and meet the evolving needs of the market. By doing so, they can ensure that their vehicles are not only safe and reliable but also capable of delivering the performance and comfort that consumers expect. The Global Fatigue Tester for Automotive Market is a critical component of the automotive industry's commitment to quality and innovation, playing a vital role in the development of vehicles that meet the highest standards of safety and performance.

Global Fatigue Tester for Automotive Market Outlook:

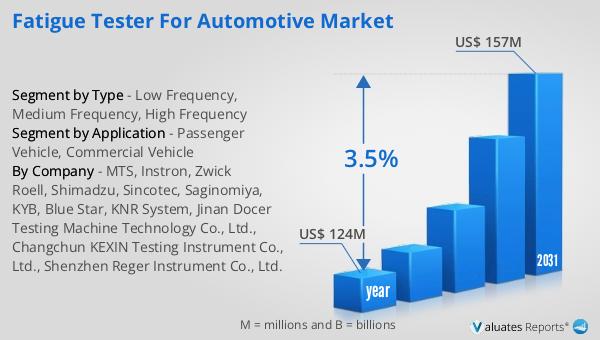

The global market for Fatigue Tester for Automotive was valued at $124 million in 2024, and it is anticipated to expand to a revised size of $157 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.5% over the forecast period. This growth trajectory underscores the increasing importance of fatigue testing in the automotive industry, driven by the need for enhanced vehicle safety, performance, and reliability. As automotive manufacturers strive to meet stringent regulatory standards and consumer expectations, the demand for advanced fatigue testing solutions is expected to rise. The market's growth is also fueled by technological advancements in testing equipment, which offer improved accuracy and efficiency. These innovations enable manufacturers to conduct more comprehensive and precise evaluations of materials and components, ensuring that vehicles can withstand the stresses and strains of real-world conditions. Additionally, the shift towards lightweight materials and the increasing complexity of vehicle designs further contribute to the demand for fatigue testing. As the market continues to evolve, manufacturers must invest in state-of-the-art testing technologies to remain competitive and meet the growing needs of the automotive industry. The projected growth of the Global Fatigue Tester for Automotive Market highlights its critical role in ensuring the safety and reliability of vehicles worldwide.

| Report Metric | Details |

| Report Name | Fatigue Tester for Automotive Market |

| Accounted market size in year | US$ 124 million |

| Forecasted market size in 2031 | US$ 157 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MTS, Instron, Zwick Roell, Shimadzu, Sincotec, Saginomiya, KYB, Blue Star, KNR System, Jinan Docer Testing Machine Technology Co., Ltd., Changchun KEXIN Testing Instrument Co., Ltd., Shenzhen Reger Instrument Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |