What is Global Full-Waste Stripping Die-Cut Machine Market?

The Global Full-Waste Stripping Die-Cut Machine Market is a specialized segment within the broader machinery industry, focusing on machines designed to enhance the efficiency and precision of die-cutting processes. These machines are integral in industries where precision cutting of materials is required, such as in the production of packaging, labels, and other paper or cardboard products. The term "full-waste stripping" refers to the machine's ability to remove excess material from the die-cut product, ensuring a clean and precise finish. This capability is crucial for maintaining high-quality standards in production, reducing waste, and improving overall operational efficiency. The market for these machines is driven by the increasing demand for high-quality packaging and labeling solutions across various industries, including food and beverage, pharmaceuticals, and consumer goods. As companies strive to enhance their product presentation and reduce material waste, the adoption of full-waste stripping die-cut machines is expected to grow. These machines not only improve the aesthetic appeal of the final product but also contribute to more sustainable manufacturing practices by minimizing waste.

Standalone, Online in the Global Full-Waste Stripping Die-Cut Machine Market:

In the Global Full-Waste Stripping Die-Cut Machine Market, the distinction between standalone and online machines is significant, as each type serves different operational needs and offers unique advantages. Standalone machines are typically used in environments where flexibility and independence from other systems are prioritized. These machines operate independently, allowing manufacturers to integrate them into existing production lines without the need for extensive modifications. Standalone die-cut machines are often favored by smaller operations or those with specific, niche production requirements. They offer the advantage of being easily movable and adaptable to different production settings, making them ideal for companies that require versatility in their manufacturing processes. On the other hand, online die-cut machines are integrated into a continuous production line, offering seamless operation and higher efficiency. These machines are designed to work in tandem with other machinery, such as printing presses or laminators, to provide a streamlined production process. Online machines are typically used in larger manufacturing environments where high-volume production is required. They offer the benefit of reduced manual intervention, as the entire process from material feeding to die-cutting and waste stripping is automated. This integration leads to faster production times and reduced labor costs, making online machines a preferred choice for large-scale manufacturers. The choice between standalone and online machines often depends on the specific needs of the manufacturer, including production volume, available space, and budget. While standalone machines offer flexibility and ease of integration, online machines provide efficiency and automation, catering to different segments of the market. As the demand for high-quality die-cut products continues to rise, manufacturers are increasingly investing in both types of machines to meet diverse production needs. The decision to invest in standalone or online machines is also influenced by technological advancements and the availability of skilled labor. As technology continues to evolve, both standalone and online machines are becoming more sophisticated, offering enhanced features such as digital controls, improved precision, and faster operation. These advancements are making it easier for manufacturers to achieve high-quality results while reducing operational costs. Additionally, the availability of skilled labor to operate these machines is a crucial factor in the decision-making process. Manufacturers must consider the level of expertise required to operate and maintain these machines, as well as the training and support provided by machine suppliers. In conclusion, the Global Full-Waste Stripping Die-Cut Machine Market offers a range of options for manufacturers, with standalone and online machines catering to different operational needs. As the market continues to grow, manufacturers are likely to invest in both types of machines to enhance their production capabilities and meet the increasing demand for high-quality die-cut products.

Labels, Packaging, Other in the Global Full-Waste Stripping Die-Cut Machine Market:

The usage of Global Full-Waste Stripping Die-Cut Machines spans across various industries, with significant applications in labels, packaging, and other sectors. In the labels industry, these machines are essential for producing high-quality, precisely cut labels that meet the stringent standards of modern branding and packaging. Labels are a critical component of product presentation, providing essential information and enhancing brand visibility. Full-waste stripping die-cut machines ensure that labels are cut with precision, eliminating excess material and ensuring a clean finish. This precision is crucial for maintaining the integrity of the label design and ensuring that it adheres properly to the product surface. In the packaging industry, full-waste stripping die-cut machines play a vital role in the production of boxes, cartons, and other packaging materials. The demand for innovative and aesthetically pleasing packaging solutions is on the rise, driven by consumer preferences and the need for differentiation in a competitive market. These machines enable manufacturers to produce intricate designs and shapes, enhancing the visual appeal of packaging while maintaining structural integrity. The ability to remove excess material efficiently also contributes to cost savings and sustainability by reducing waste. Beyond labels and packaging, full-waste stripping die-cut machines find applications in other areas such as the production of greeting cards, promotional materials, and decorative items. In these sectors, the machines are used to create intricate designs and patterns that require high precision and attention to detail. The versatility of these machines allows manufacturers to experiment with different materials and designs, catering to diverse consumer preferences and market trends. The ability to produce high-quality, customized products is a significant advantage in these industries, where personalization and uniqueness are highly valued. Overall, the usage of full-waste stripping die-cut machines in labels, packaging, and other sectors highlights their importance in modern manufacturing. These machines not only enhance the quality and precision of the final product but also contribute to more efficient and sustainable production processes. As industries continue to evolve and consumer demands shift, the adoption of these machines is expected to grow, driven by the need for high-quality, innovative, and sustainable solutions.

Global Full-Waste Stripping Die-Cut Machine Market Outlook:

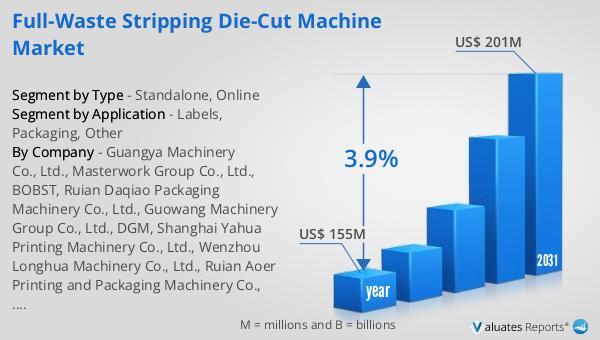

The global market for Full-Waste Stripping Die-Cut Machines was valued at $155 million in 2024, with projections indicating an increase to $201 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.9% over the forecast period. This growth trajectory underscores the increasing demand for precision cutting solutions across various industries. The market's expansion is driven by the rising need for high-quality packaging and labeling solutions, as well as the growing emphasis on sustainability and waste reduction in manufacturing processes. As companies strive to enhance their product presentation and reduce material waste, the adoption of full-waste stripping die-cut machines is expected to grow. These machines not only improve the aesthetic appeal of the final product but also contribute to more sustainable manufacturing practices by minimizing waste. The projected growth of the market highlights the importance of these machines in modern manufacturing, as they offer a combination of precision, efficiency, and sustainability. As industries continue to evolve and consumer demands shift, the adoption of these machines is expected to grow, driven by the need for high-quality, innovative, and sustainable solutions. The market outlook for full-waste stripping die-cut machines is positive, with steady growth anticipated over the coming years.

| Report Metric | Details |

| Report Name | Full-Waste Stripping Die-Cut Machine Market |

| Accounted market size in year | US$ 155 million |

| Forecasted market size in 2031 | US$ 201 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Guangya Machinery Co., Ltd., Masterwork Group Co., Ltd., BOBST, Ruian Daqiao Packaging Machinery Co., Ltd., Guowang Machinery Group Co., Ltd., DGM, Shanghai Yahua Printing Machinery Co., Ltd., Wenzhou Longhua Machinery Co., Ltd., Ruian Aoer Printing and Packaging Machinery Co., Ltd., Tangshan Yuyin Co., Ltd., Xinchuan Machinery, Shanghai PrintYoung International Industry Co., Ltd, Koten Machinery, Trugen Machinery, Zhejiang Feida Machinery Co., Ltd., Shanghai Eternal Machinery Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |