What is Global Intelligent CNC Woodworking Machines Market?

The Global Intelligent CNC Woodworking Machines Market represents a rapidly evolving segment within the woodworking industry, characterized by the integration of advanced computer numerical control (CNC) technology into woodworking machinery. These machines are designed to enhance precision, efficiency, and automation in woodworking processes, catering to a wide range of applications from furniture manufacturing to intricate architectural designs. The market is driven by the increasing demand for high-quality, customized wood products and the need for efficient production processes. Intelligent CNC woodworking machines are equipped with sophisticated software and sensors that allow for precise control over cutting, engraving, drilling, and other woodworking operations. This technology not only improves the accuracy and speed of production but also reduces material waste and labor costs. As industries continue to embrace automation and digitalization, the adoption of intelligent CNC woodworking machines is expected to grow, offering significant opportunities for innovation and development in woodworking techniques and applications. The market's growth is further supported by advancements in machine learning and artificial intelligence, which are being integrated into CNC systems to enhance their capabilities and adaptability to complex woodworking tasks.

CNC Engraving Machines, CNC Tenoning Machines, CNC Drilling Machines, CNC Cutting Machines, Others in the Global Intelligent CNC Woodworking Machines Market:

CNC Engraving Machines are a vital component of the Global Intelligent CNC Woodworking Machines Market, designed to perform intricate engraving tasks with high precision and speed. These machines utilize advanced software to control the movement of the engraving tool, allowing for detailed designs and patterns to be carved into wood surfaces. They are widely used in creating decorative elements, personalized items, and intricate designs in furniture and architectural components. CNC Tenoning Machines, on the other hand, are specialized for creating tenons, which are essential for joining pieces of wood together in furniture and cabinetry. These machines ensure that tenons are cut with exact dimensions and angles, facilitating strong and precise joints. CNC Drilling Machines are employed for creating holes in wood with high accuracy, essential for assembling furniture and other wooden structures. They are capable of drilling multiple holes in a single operation, significantly speeding up the production process. CNC Cutting Machines are versatile tools used for cutting wood into various shapes and sizes. They are equipped with powerful cutting tools and advanced control systems that allow for precise and efficient cutting operations, reducing material waste and improving productivity. Other machines in this market include CNC routers and CNC lathes, which offer additional capabilities such as shaping and turning wood into complex forms. These machines are integral to modern woodworking, providing the flexibility and precision needed to meet the demands of diverse applications. The integration of intelligent features, such as real-time monitoring and adaptive control, further enhances the performance and efficiency of these machines, making them indispensable in the woodworking industry.

Furniture Manufacturing, Cabinet Making, Architectural Woodworking, Interior Decoration, Others in the Global Intelligent CNC Woodworking Machines Market:

The usage of Global Intelligent CNC Woodworking Machines Market spans several key areas, each benefiting from the precision and efficiency offered by these advanced machines. In furniture manufacturing, CNC machines are used to produce high-quality furniture pieces with intricate designs and precise dimensions. The ability to automate complex cutting, drilling, and engraving tasks allows manufacturers to create customized furniture with ease, meeting the growing demand for personalized products. Cabinet making also benefits significantly from CNC technology, as these machines can produce cabinet components with exact measurements and seamless joints, ensuring a perfect fit and finish. In architectural woodworking, CNC machines are employed to create detailed architectural elements such as moldings, trims, and decorative panels. The precision and versatility of CNC machines enable architects and designers to bring their creative visions to life, producing unique and intricate designs that enhance the aesthetic appeal of buildings. Interior decoration is another area where CNC woodworking machines play a crucial role. From creating custom wall panels to intricate ceiling designs, these machines allow for the production of decorative elements that add character and style to interior spaces. Other applications of CNC woodworking machines include the production of musical instruments, toys, and various wooden artifacts, where precision and detail are paramount. The integration of intelligent features in these machines further enhances their capabilities, allowing for real-time adjustments and optimization of production processes. This not only improves the quality and consistency of the final products but also reduces production time and costs, making CNC woodworking machines an invaluable asset in various industries.

Global Intelligent CNC Woodworking Machines Market Outlook:

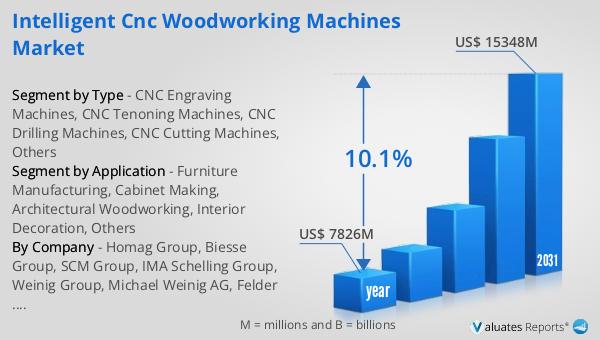

The global market for Intelligent CNC Woodworking Machines was valued at $7,826 million in 2024, and it is anticipated to expand significantly, reaching an estimated $15,348 million by 2031. This growth represents a compound annual growth rate (CAGR) of 10.1% over the forecast period. The increasing demand for precision and efficiency in woodworking processes is a key driver of this market expansion. As industries continue to seek ways to enhance productivity and reduce costs, the adoption of intelligent CNC woodworking machines is expected to rise. These machines offer advanced capabilities, such as real-time monitoring and adaptive control, which improve the accuracy and speed of production. Additionally, the integration of machine learning and artificial intelligence into CNC systems is further enhancing their performance and adaptability to complex woodworking tasks. The market's growth is also supported by the rising demand for customized wood products, which require precise and efficient production processes. As a result, the Global Intelligent CNC Woodworking Machines Market is poised for significant growth, offering numerous opportunities for innovation and development in woodworking techniques and applications.

| Report Metric | Details |

| Report Name | Intelligent CNC Woodworking Machines Market |

| Accounted market size in year | US$ 7826 million |

| Forecasted market size in 2031 | US$ 15348 million |

| CAGR | 10.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Homag Group, Biesse Group, SCM Group, IMA Schelling Group, Weinig Group, Michael Weinig AG, Felder Group, Greda srl, Anderson Group, Masterwood, Nanxing Machinery, HOLZ-HER, KDT Machinery, HOMAG China, CEHISA, MAKA Systems GmbH, Altendorf Group, Reichenbacher Hamuel GmbH, Weeke Bohrsysteme GmbH, Format-4, Komo Machine Inc., Thermwood Corporation, AXYZ Automation Group, Bacci, Griggio Srl, Cosmec Technology, CMS Industries, Barbaric GmbH, Laguna Tools, Casadei Industria |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |