What is Global Electrodynamic Fatigue Testing Machine Market?

The Global Electrodynamic Fatigue Testing Machine Market is a specialized segment within the broader testing equipment industry, focusing on machines designed to evaluate the durability and performance of materials and components under cyclic loading conditions. These machines simulate real-world stressors that materials might encounter during their lifecycle, such as vibrations, repeated loads, and other dynamic forces. By doing so, they help manufacturers and researchers understand how materials will behave under prolonged use, ensuring safety, reliability, and efficiency. The market for these machines is driven by the increasing demand for high-performance materials in various industries, including automotive, aerospace, and industrial manufacturing. As industries strive for innovation and enhanced product performance, the need for precise and reliable testing equipment becomes paramount. Electrodynamic fatigue testing machines are particularly valued for their ability to provide accurate and repeatable results, making them indispensable tools in quality assurance and product development processes. With advancements in technology, these machines are becoming more sophisticated, offering enhanced capabilities such as higher load capacities, improved data acquisition systems, and user-friendly interfaces. This evolution is expected to continue, driven by the ongoing demand for more robust and efficient testing solutions across multiple sectors.

1kN, 3kN, 5kN, 10kN, Others in the Global Electrodynamic Fatigue Testing Machine Market:

In the Global Electrodynamic Fatigue Testing Machine Market, machines are categorized based on their load capacities, which are typically measured in kilonewtons (kN). The 1kN machines are designed for testing smaller components and materials that require lower force applications. These machines are often used in industries where precision and sensitivity are crucial, such as electronics and small-scale manufacturing. They provide detailed insights into the fatigue characteristics of materials, helping manufacturers ensure that even the smallest components meet quality and durability standards. Moving up the scale, 3kN machines offer a higher load capacity, making them suitable for medium-sized components and materials. These machines are versatile and can be used in a variety of applications, from testing automotive parts to evaluating the durability of consumer goods. Their ability to handle moderate loads makes them a popular choice for manufacturers looking to balance precision with capacity. The 5kN machines represent a further step up in terms of load capacity, catering to industries that require testing of larger components and materials. These machines are commonly used in sectors such as construction and heavy machinery, where the materials and components are subject to significant stress and strain. The 5kN machines provide the necessary force to simulate real-world conditions, ensuring that products can withstand the demands of their intended applications. At the higher end of the spectrum, 10kN machines are designed for the most demanding testing scenarios. These machines are capable of applying significant forces, making them ideal for testing large components and materials used in industries such as aerospace and defense. The ability to simulate extreme conditions is crucial in these sectors, where safety and reliability are of paramount importance. In addition to these standard capacities, the market also offers machines with other load capacities to meet specific industry needs. These machines are often customized to provide the precise testing capabilities required for unique applications. The diversity in load capacities reflects the wide range of industries and applications that rely on electrodynamic fatigue testing machines. As technology continues to advance, the capabilities of these machines are expected to expand, offering even greater precision and versatility to meet the evolving needs of manufacturers and researchers.

Automotive, Industrial Manufacturing, Aerospace, Research Institution, Others in the Global Electrodynamic Fatigue Testing Machine Market:

The Global Electrodynamic Fatigue Testing Machine Market finds extensive usage across various industries, each with its unique requirements and challenges. In the automotive sector, these machines are crucial for testing the durability and performance of vehicle components such as suspension systems, chassis, and engine parts. The ability to simulate real-world driving conditions allows manufacturers to ensure that their vehicles can withstand the stresses of everyday use, enhancing safety and reliability. In industrial manufacturing, electrodynamic fatigue testing machines are used to evaluate the performance of materials and components used in machinery and equipment. This is particularly important in industries where equipment is subject to constant use and must maintain high levels of performance over time. By identifying potential weaknesses and failure points, manufacturers can improve the design and quality of their products, reducing downtime and maintenance costs. The aerospace industry relies heavily on these machines to test the durability of aircraft components, which are subject to extreme conditions during flight. Ensuring the reliability of these components is critical to maintaining safety standards and preventing catastrophic failures. Electrodynamic fatigue testing machines provide the precision and accuracy needed to evaluate the performance of materials used in aircraft construction, from the fuselage to the wings and engines. Research institutions also utilize these machines to study the fatigue characteristics of new materials and develop innovative solutions for various applications. By understanding how materials behave under cyclic loading, researchers can develop new alloys, composites, and other materials that offer improved performance and durability. This research is essential for advancing technology and driving innovation across multiple industries. Beyond these primary sectors, electrodynamic fatigue testing machines are used in a variety of other applications, from testing consumer electronics to evaluating the performance of medical devices. The versatility of these machines makes them valuable tools for any industry that requires precise and reliable testing of materials and components. As industries continue to evolve and demand higher performance from their products, the role of electrodynamic fatigue testing machines will only become more critical. Their ability to provide accurate and repeatable results ensures that manufacturers can meet the stringent quality and safety standards required in today's competitive market.

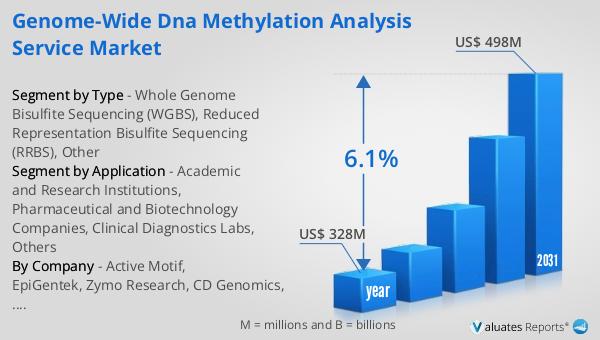

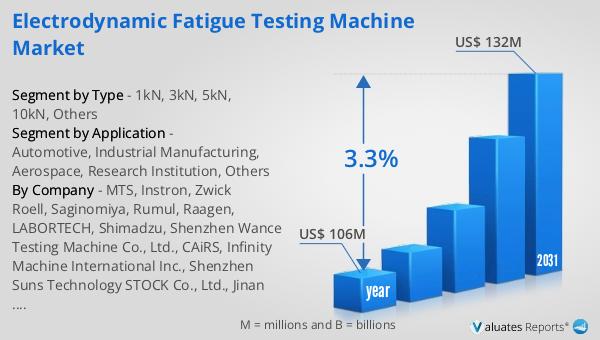

Global Electrodynamic Fatigue Testing Machine Market Outlook:

The global market for Electrodynamic Fatigue Testing Machines was valued at approximately $106 million in 2024, with projections indicating that it will grow to around $132 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.3% over the forecast period. This steady increase in market size reflects the rising demand for advanced testing solutions across various industries. As manufacturers and researchers continue to seek more reliable and efficient ways to evaluate the performance and durability of materials and components, the need for high-quality testing equipment becomes increasingly important. The growth of this market is driven by several factors, including technological advancements in testing equipment, the increasing complexity of materials and components, and the growing emphasis on quality assurance and safety standards. As industries continue to innovate and develop new products, the demand for precise and reliable testing solutions will only increase. This trend is expected to continue as manufacturers strive to meet the evolving needs of their customers and maintain a competitive edge in the global market. The projected growth of the Electrodynamic Fatigue Testing Machine Market underscores the importance of these machines in ensuring the quality and reliability of products across multiple sectors.

| Report Metric | Details |

| Report Name | Electrodynamic Fatigue Testing Machine Market |

| Accounted market size in year | US$ 106 million |

| Forecasted market size in 2031 | US$ 132 million |

| CAGR | 3.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MTS, Instron, Zwick Roell, Saginomiya, Rumul, Raagen, LABORTECH, Shimadzu, Shenzhen Wance Testing Machine Co., Ltd., CAiRS, Infinity Machine International Inc., Shenzhen Suns Technology STOCK Co., Ltd., Jinan Docer Testing Machine Technology Co., Ltd., Changchun KEXIN Testing Instrument Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |