What is Global Rigid PVC Granule Compound Market?

The Global Rigid PVC Granule Compound Market is a significant segment within the broader plastics industry, focusing on the production and application of rigid polyvinyl chloride (PVC) granules. These granules are a type of thermoplastic polymer that is widely used due to their durability, cost-effectiveness, and versatility. Rigid PVC granules are primarily utilized in applications that require a strong, durable material that can withstand various environmental conditions. The market for these compounds is driven by their extensive use in construction, automotive, electrical, and packaging industries, among others. The demand for rigid PVC granules is also influenced by their recyclability and the increasing emphasis on sustainable materials. As industries continue to seek materials that offer both performance and environmental benefits, the Global Rigid PVC Granule Compound Market is expected to grow, adapting to new technological advancements and regulatory standards. This market is characterized by a diverse range of products tailored to meet specific industry needs, making it a dynamic and evolving sector within the global economy.

Phthalates Compound, Non-phthalates Compound in the Global Rigid PVC Granule Compound Market:

Phthalates and non-phthalates compounds are crucial components in the Global Rigid PVC Granule Compound Market, each serving distinct roles and catering to different industry needs. Phthalates are a group of chemical compounds primarily used as plasticizers, substances added to plastics to increase their flexibility, transparency, durability, and longevity. In the context of rigid PVC granules, phthalates help in enhancing the material's performance characteristics, making it suitable for a wide range of applications. However, the use of phthalates has been a subject of concern due to potential health and environmental risks. This has led to increased regulatory scrutiny and a shift towards non-phthalate alternatives. Non-phthalate compounds, on the other hand, are developed to provide similar plasticizing effects without the associated health risks. These compounds are gaining popularity as safer alternatives, especially in applications where human exposure is significant, such as in medical devices, children's toys, and food packaging. The transition from phthalates to non-phthalates is driven by consumer demand for safer products and stricter regulatory frameworks aimed at reducing harmful chemical exposure. This shift is also supported by advancements in chemical engineering, which have enabled the development of effective non-phthalate plasticizers that do not compromise on performance. The choice between phthalates and non-phthalates in rigid PVC granules depends on several factors, including regulatory requirements, cost considerations, and specific application needs. While phthalates continue to be used in many industrial applications due to their cost-effectiveness and proven performance, non-phthalates are increasingly being adopted in sectors where safety and environmental impact are paramount. This dual approach allows the Global Rigid PVC Granule Compound Market to cater to a broad spectrum of industries, balancing performance with safety and sustainability. As the market evolves, the development of new and improved non-phthalate compounds is expected to play a significant role in shaping the future of rigid PVC granules, offering solutions that meet the growing demand for safer and more sustainable materials.

Construction and Building Materials, Electrical and Electronics, Industrial Applications, Consumer Goods and Packaging, Medical, Other in the Global Rigid PVC Granule Compound Market:

The Global Rigid PVC Granule Compound Market finds extensive usage across various sectors, each benefiting from the unique properties of rigid PVC. In the construction and building materials industry, rigid PVC granules are used to manufacture pipes, fittings, window frames, and other structural components. Their durability, resistance to weathering, and low maintenance requirements make them ideal for construction applications. In the electrical and electronics sector, rigid PVC is used for insulation, cable sheathing, and other components that require fire resistance and electrical insulation properties. The material's ability to withstand high temperatures and resist electrical conductivity makes it a preferred choice for electrical applications. In industrial applications, rigid PVC granules are used to produce components that require high strength and chemical resistance, such as tanks, valves, and industrial flooring. The consumer goods and packaging industry also utilizes rigid PVC for products like bottles, containers, and packaging films, benefiting from its clarity, strength, and barrier properties. In the medical field, rigid PVC is used to manufacture medical devices, tubing, and containers, where its biocompatibility and sterilization capabilities are crucial. Other applications include automotive components, furniture, and toys, where the material's versatility and performance characteristics are leveraged. The widespread use of rigid PVC granules across these sectors highlights the material's adaptability and the market's ability to meet diverse industry needs. As industries continue to innovate and seek materials that offer both performance and sustainability, the Global Rigid PVC Granule Compound Market is poised to play a critical role in supporting these advancements.

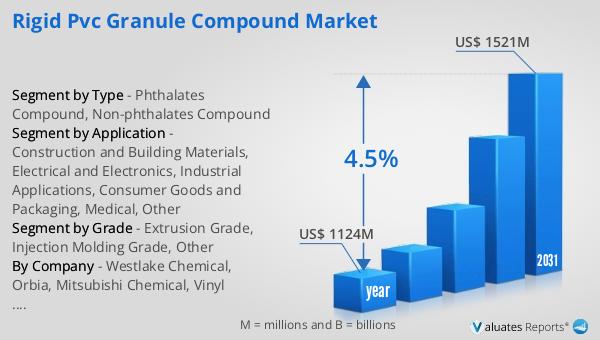

Global Rigid PVC Granule Compound Market Outlook:

The global market for Rigid PVC Granule Compound was valued at $1,124 million in 2024 and is anticipated to expand to a revised size of $1,521 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.5% over the forecast period. This growth trajectory underscores the increasing demand for rigid PVC granules across various industries, driven by their unique properties and versatility. The market's expansion is fueled by the rising need for durable, cost-effective, and sustainable materials in construction, automotive, electrical, and packaging sectors. As industries continue to prioritize materials that offer both performance and environmental benefits, the demand for rigid PVC granules is expected to rise. The projected growth also highlights the market's adaptability to evolving industry needs and regulatory standards, as well as its ability to incorporate technological advancements. This positive outlook for the Global Rigid PVC Granule Compound Market reflects the material's critical role in supporting industrial innovation and sustainability efforts. As the market continues to evolve, it is likely to witness further developments in product offerings and applications, catering to the diverse needs of industries worldwide.

| Report Metric | Details |

| Report Name | Rigid PVC Granule Compound Market |

| Accounted market size in year | US$ 1124 million |

| Forecasted market size in 2031 | US$ 1521 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Grade |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Westlake Chemical, Orbia, Mitsubishi Chemical, Vinyl Compounds N.A., Aurora Plastics, Benvic Group, INEOS Compounds, Teknor Apex, Flex Technologies, Empol (IFFCO), GEON Performance Solutions, Konnark Polymer, Mazda Plastic, Thevinyl, RIKEN, SCG Chemicalss, Color Master, Manner Polymers, Intek Plastics, Hanwha, Kingfa Sci.& Tech., Guangdong Silver Age Sci & Tech, Tatsuta Chemical, NAN YA PLASTICS, ZEON KASEI |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |