What is Global Defoamer for Metalworking Fluids Market?

The Global Defoamer for Metalworking Fluids Market is a specialized segment within the broader industrial chemicals industry, focusing on the production and application of defoamers specifically designed for metalworking fluids. Metalworking fluids are essential in various manufacturing processes, including cutting, grinding, and machining, as they help in cooling and lubricating the tools and workpieces. However, these fluids often generate foam during use, which can hinder the efficiency of the process and affect the quality of the finished product. Defoamers are added to these fluids to reduce or eliminate foam, ensuring smooth operation and optimal performance. The global market for these defoamers is driven by the increasing demand for high-quality metalworking processes across various industries, including automotive, aerospace, and heavy machinery. As manufacturers strive for greater efficiency and precision, the need for effective defoamers becomes more critical. The market is characterized by a diverse range of products, including silicone-based, polyether-based, and mineral oil-based defoamers, each offering unique properties and benefits. With advancements in technology and growing environmental concerns, the market is also witnessing a shift towards more sustainable and eco-friendly defoamer solutions.

Silicones, Polyethers, Mineral Oils, Others in the Global Defoamer for Metalworking Fluids Market:

Silicones, polyethers, mineral oils, and other compounds play a crucial role in the Global Defoamer for Metalworking Fluids Market, each offering distinct advantages and applications. Silicones are among the most popular defoamers due to their excellent stability and effectiveness in a wide range of temperatures and pH levels. They are particularly valued for their ability to provide long-lasting foam control without affecting the properties of the metalworking fluids. Silicone defoamers are often used in applications where high performance and durability are required, such as in the automotive and aerospace industries. Polyethers, on the other hand, are known for their compatibility with various metalworking fluids and their ability to provide rapid foam knockdown. They are often used in situations where quick defoaming action is needed, such as in high-speed machining processes. Polyether defoamers are also appreciated for their low toxicity and environmental impact, making them a preferred choice for manufacturers seeking sustainable solutions. Mineral oil-based defoamers are another important category, offering cost-effective foam control for a wide range of applications. These defoamers are particularly effective in controlling foam in oil-based metalworking fluids, providing a balance between performance and cost. However, they may not be suitable for all applications, especially those requiring high-temperature stability or low environmental impact. In addition to these main categories, there are also other types of defoamers available in the market, including those based on natural oils and esters. These alternative defoamers are gaining popularity due to their biodegradability and reduced environmental footprint. As the market continues to evolve, manufacturers are increasingly focusing on developing innovative defoamer solutions that meet the specific needs of different metalworking processes while also addressing environmental and regulatory concerns. This has led to the development of hybrid defoamers that combine the benefits of different compounds, offering enhanced performance and versatility. Overall, the choice of defoamer depends on various factors, including the type of metalworking fluid, the specific application requirements, and the environmental considerations. As industries continue to demand higher efficiency and sustainability, the Global Defoamer for Metalworking Fluids Market is expected to see continued growth and innovation in the coming years.

Mechanical Processing, Metallurgy, Automotive, Others in the Global Defoamer for Metalworking Fluids Market:

The usage of Global Defoamer for Metalworking Fluids Market spans across various industries, including mechanical processing, metallurgy, automotive, and others, each with its unique requirements and challenges. In mechanical processing, defoamers are essential for maintaining the efficiency and quality of operations such as cutting, grinding, and milling. Foam can interfere with the cooling and lubricating properties of metalworking fluids, leading to increased tool wear and poor surface finish. By effectively controlling foam, defoamers help ensure smooth operation and extend the life of tools and equipment. In the metallurgy industry, defoamers play a critical role in processes such as casting, forging, and rolling. These processes often involve high temperatures and complex fluid dynamics, making foam control essential for maintaining product quality and process efficiency. Defoamers help prevent defects and inconsistencies in the final product, ensuring that the metal components meet the required specifications. In the automotive industry, defoamers are used in various manufacturing processes, including engine and transmission assembly, where precision and reliability are paramount. Foam can lead to air entrapment and other issues that compromise the performance and durability of automotive components. By eliminating foam, defoamers help ensure that the manufacturing processes run smoothly and produce high-quality parts. Beyond these industries, defoamers are also used in other sectors such as aerospace, heavy machinery, and electronics, where metalworking fluids are critical to the manufacturing process. In each of these applications, the choice of defoamer depends on factors such as the type of metalworking fluid, the specific process requirements, and environmental considerations. As industries continue to evolve and demand higher efficiency and sustainability, the Global Defoamer for Metalworking Fluids Market is expected to see continued growth and innovation, with manufacturers developing new and improved defoamer solutions to meet the changing needs of their customers.

Global Defoamer for Metalworking Fluids Market Outlook:

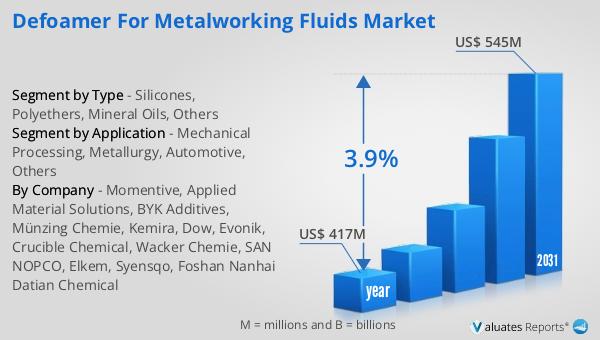

The global market for Defoamer for Metalworking Fluids was valued at $417 million in 2024, and it is anticipated to grow to a revised size of $545 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.9% during the forecast period. This growth trajectory underscores the increasing demand for effective foam control solutions in metalworking processes across various industries. The steady rise in market value can be attributed to several factors, including the growing emphasis on improving manufacturing efficiency and product quality. As industries such as automotive, aerospace, and heavy machinery continue to expand, the need for high-performance metalworking fluids and defoamers becomes more critical. Additionally, the shift towards more sustainable and environmentally friendly manufacturing practices is driving the development and adoption of innovative defoamer solutions. Manufacturers are investing in research and development to create products that not only deliver superior foam control but also meet stringent environmental regulations. This focus on sustainability is expected to further propel the market's growth in the coming years. Overall, the Global Defoamer for Metalworking Fluids Market is poised for steady expansion, driven by technological advancements, increasing industrialization, and the ongoing pursuit of efficiency and sustainability in manufacturing processes.

| Report Metric | Details |

| Report Name | Defoamer for Metalworking Fluids Market |

| Accounted market size in year | US$ 417 million |

| Forecasted market size in 2031 | US$ 545 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Momentive, Applied Material Solutions, BYK Additives, Münzing Chemie, Kemira, Dow, Evonik, Crucible Chemical, Wacker Chemie, SAN NOPCO, Elkem, Syensqo, Foshan Nanhai Datian Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |