What is Global PEEK CNC Machining Services Market?

The Global PEEK CNC Machining Services Market is a specialized sector within the broader manufacturing industry that focuses on the precision machining of PEEK (Polyether Ether Ketone) materials using CNC (Computer Numerical Control) technology. PEEK is a high-performance engineering thermoplastic known for its exceptional mechanical properties, chemical resistance, and thermal stability, making it ideal for demanding applications across various industries. CNC machining services for PEEK involve the use of computer-controlled machines to precisely cut, shape, and finish PEEK components according to specific design requirements. This market caters to industries such as aerospace, medical, automotive, electronics, and industrial manufacturing, where the demand for high-quality, durable, and lightweight components is critical. The growth of this market is driven by the increasing adoption of PEEK materials in advanced engineering applications, the need for precision manufacturing, and the rising demand for customized components. As industries continue to innovate and seek materials that offer superior performance, the Global PEEK CNC Machining Services Market is poised to expand, offering opportunities for manufacturers and service providers to meet the evolving needs of their clients.

CNC Milling, CNC Turning, 5-axis Machining, Others in the Global PEEK CNC Machining Services Market:

CNC Milling, CNC Turning, 5-axis Machining, and other machining processes play a crucial role in the Global PEEK CNC Machining Services Market. CNC Milling involves the use of rotary cutters to remove material from a PEEK workpiece, allowing for the creation of complex shapes and features with high precision. This process is particularly useful for producing intricate components that require tight tolerances and smooth finishes. CNC Turning, on the other hand, involves rotating the PEEK workpiece while a cutting tool shapes it, making it ideal for creating cylindrical parts such as shafts, bushings, and fittings. This process is highly efficient for producing symmetrical components with consistent dimensions. 5-axis Machining is an advanced CNC process that allows for the simultaneous movement of the cutting tool along five different axes, enabling the production of highly complex and detailed parts. This capability is essential for industries that require intricate geometries and precise machining, such as aerospace and medical device manufacturing. Other machining processes in the PEEK CNC Machining Services Market include drilling, tapping, and threading, which are used to create holes, threads, and other features in PEEK components. These processes are essential for ensuring that the final product meets the specific requirements of the application. The choice of machining process depends on factors such as the complexity of the design, the required tolerances, and the intended use of the component. As the demand for high-performance PEEK components continues to grow, the Global PEEK CNC Machining Services Market is expected to expand, offering a wide range of machining solutions to meet the diverse needs of various industries.

Aerospace, Medical, Automotive, Electronic and Electronics, Industrial Manufacturing, Chemicals, Semiconductor, Others in the Global PEEK CNC Machining Services Market:

The Global PEEK CNC Machining Services Market finds extensive usage across several key industries, each benefiting from the unique properties of PEEK and the precision of CNC machining. In the aerospace sector, PEEK components are valued for their lightweight nature, high strength, and resistance to extreme temperatures and chemicals. These properties make PEEK ideal for use in aircraft interiors, structural components, and engine parts, where performance and reliability are paramount. In the medical field, PEEK is used to manufacture implants, surgical instruments, and other medical devices due to its biocompatibility, sterilization capability, and mechanical properties that mimic human bone. The automotive industry utilizes PEEK CNC machining services to produce components that require high thermal stability, wear resistance, and reduced weight, such as gears, bearings, and under-the-hood parts. In the electronics and electronics sector, PEEK is used for insulating components, connectors, and semiconductor manufacturing equipment, thanks to its excellent electrical insulation properties and resistance to high temperatures. Industrial manufacturing benefits from PEEK's durability and chemical resistance, making it suitable for producing parts that withstand harsh environments and demanding conditions. The chemical industry uses PEEK components in pumps, valves, and seals due to their ability to resist corrosive substances and maintain integrity under pressure. In the semiconductor industry, PEEK is used for wafer handling and processing equipment, where precision and cleanliness are critical. Other industries, such as oil and gas, food processing, and renewable energy, also leverage the advantages of PEEK CNC machining services to enhance the performance and longevity of their components. As these industries continue to evolve and demand more advanced materials and manufacturing techniques, the Global PEEK CNC Machining Services Market is poised to grow, offering innovative solutions to meet the diverse needs of its clients.

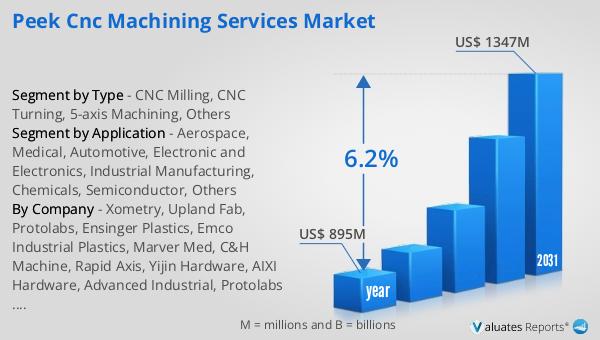

Global PEEK CNC Machining Services Market Outlook:

The global market for PEEK CNC Machining Services was valued at $895 million in 2024 and is anticipated to grow to a revised size of $1,347 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.2% during the forecast period. This growth trajectory underscores the increasing demand for PEEK CNC machining services across various industries, driven by the need for high-performance materials and precision manufacturing. The market's expansion is fueled by the rising adoption of PEEK in advanced engineering applications, where its exceptional properties, such as high strength, chemical resistance, and thermal stability, are highly valued. As industries continue to innovate and seek materials that offer superior performance, the demand for PEEK CNC machining services is expected to rise, providing opportunities for manufacturers and service providers to meet the evolving needs of their clients. The projected growth of the market highlights the importance of PEEK CNC machining services in enabling industries to achieve their goals of producing high-quality, durable, and lightweight components. As the market continues to evolve, it will be essential for stakeholders to stay abreast of the latest developments and trends to capitalize on the opportunities presented by this dynamic and growing market.

| Report Metric | Details |

| Report Name | PEEK CNC Machining Services Market |

| Accounted market size in year | US$ 895 million |

| Forecasted market size in 2031 | US$ 1347 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Xometry, Upland Fab, Protolabs, Ensinger Plastics, Emco Industrial Plastics, Marver Med, C&H Machine, Rapid Axis, Yijin Hardware, AIXI Hardware, Advanced Industrial, Protolabs Network, Prototek Digital Manufacturing, TOPS, Runsom Precision, CMG, Dadesin, RapidDirect, VMT, PEEKChina |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |