What is Global Roll-to-roll Flatbed Die-cutting Machine Market?

The Global Roll-to-roll Flatbed Die-cutting Machine Market refers to the industry focused on the production and sale of machines that are specifically designed for die-cutting processes. These machines are essential in various manufacturing sectors as they allow for the precise cutting of materials into specific shapes and sizes. The term "roll-to-roll" indicates that these machines can handle materials that are fed in rolls, making them highly efficient for continuous production processes. Flatbed die-cutting machines, in particular, use a flat surface to cut materials, which ensures accuracy and consistency in the final product. This market is driven by the increasing demand for high-quality and efficient cutting solutions in industries such as packaging, labeling, and other manufacturing sectors. As businesses strive to improve production efficiency and product quality, the demand for advanced die-cutting machines continues to grow. The market is characterized by technological advancements, with manufacturers constantly innovating to offer machines that are faster, more precise, and capable of handling a wider range of materials. This growth is further supported by the expanding global manufacturing sector, which requires reliable and efficient machinery to meet increasing production demands.

Semi-automatic, Fully Automatic in the Global Roll-to-roll Flatbed Die-cutting Machine Market:

In the Global Roll-to-roll Flatbed Die-cutting Machine Market, machines are categorized based on their level of automation, primarily into semi-automatic and fully automatic machines. Semi-automatic die-cutting machines require some level of human intervention during the operation. Operators are needed to load materials, adjust settings, and sometimes remove finished products. These machines are typically more affordable than their fully automatic counterparts and are suitable for small to medium-sized businesses that do not require high-volume production. They offer flexibility and control, allowing operators to make adjustments as needed during the cutting process. On the other hand, fully automatic die-cutting machines are designed for high efficiency and minimal human intervention. These machines can handle large volumes of material with precision and speed, making them ideal for large-scale manufacturing operations. They are equipped with advanced features such as automatic material feeding, cutting, and stacking, which significantly reduce the need for manual labor. Fully automatic machines are often integrated with digital controls and software, allowing for easy programming and operation. This level of automation not only increases production speed but also enhances accuracy and consistency in the final product. The choice between semi-automatic and fully automatic machines depends on various factors, including the scale of production, budget, and specific industry requirements. While semi-automatic machines offer cost savings and flexibility, fully automatic machines provide efficiency and high output, making them a preferred choice for large manufacturers. As technology continues to advance, the gap between these two types of machines is narrowing, with semi-automatic machines incorporating more automated features and fully automatic machines becoming more affordable. This evolution in machine technology is driven by the need for manufacturers to remain competitive in a rapidly changing market. By investing in advanced die-cutting machines, businesses can improve their production processes, reduce waste, and enhance product quality, ultimately leading to increased profitability and market share.

Labels, Packaging, Other in the Global Roll-to-roll Flatbed Die-cutting Machine Market:

The Global Roll-to-roll Flatbed Die-cutting Machine Market finds extensive usage in various areas, including labels, packaging, and other applications. In the labeling industry, these machines are crucial for producing high-quality labels with precise shapes and sizes. Labels are essential for branding, product information, and regulatory compliance, making accuracy in die-cutting vital. Roll-to-roll flatbed die-cutting machines offer the precision needed to produce intricate label designs, ensuring that each label is consistent and meets industry standards. The ability to handle large volumes of material efficiently makes these machines ideal for label manufacturers who need to meet high demand without compromising on quality. In the packaging sector, die-cutting machines play a significant role in creating custom packaging solutions. Packaging is not only about protecting products but also about enhancing their appeal and providing information to consumers. Roll-to-roll flatbed die-cutting machines enable manufacturers to produce packaging with unique shapes and designs, helping brands stand out in a competitive market. These machines can handle a variety of materials, including cardboard, plastic, and paper, allowing for versatility in packaging design. Additionally, the efficiency of these machines ensures that packaging production is cost-effective and timely, meeting the needs of fast-paced manufacturing environments. Beyond labels and packaging, roll-to-roll flatbed die-cutting machines are used in other industries such as automotive, electronics, and textiles. In the automotive industry, these machines are used to produce components like gaskets and seals, which require precise cutting for proper fit and function. In electronics, die-cutting machines are used to create components like circuit boards and protective films. The textile industry also benefits from these machines, as they can cut fabrics into specific patterns for clothing and other products. The versatility and precision of roll-to-roll flatbed die-cutting machines make them indispensable in these industries, where accuracy and efficiency are paramount. As demand for customized and high-quality products continues to grow, the usage of these machines is expected to expand, driving further innovation and development in the market.

Global Roll-to-roll Flatbed Die-cutting Machine Market Outlook:

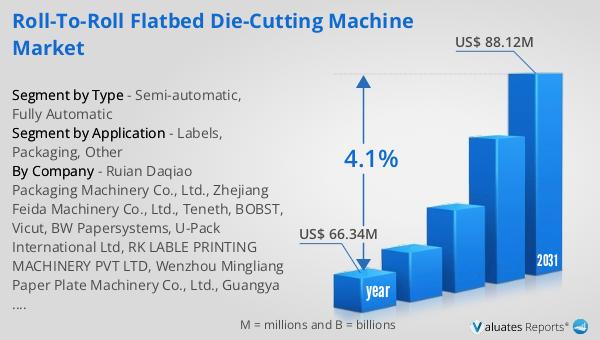

The outlook for the Global Roll-to-roll Flatbed Die-cutting Machine Market indicates a promising future. In 2024, the market was valued at approximately $66.34 million, reflecting the significant demand for these machines across various industries. By 2031, the market is projected to grow to a revised size of $88.12 million, demonstrating a steady compound annual growth rate (CAGR) of 4.1% during the forecast period. This growth is attributed to the increasing need for efficient and precise cutting solutions in manufacturing processes. As industries continue to evolve and demand higher quality and more customized products, the role of advanced die-cutting machines becomes even more critical. The market's expansion is supported by technological advancements that enhance the capabilities of these machines, making them more efficient and versatile. Manufacturers are investing in research and development to introduce innovative features that cater to the diverse needs of different industries. The growing emphasis on automation and digitalization in manufacturing processes also contributes to the market's growth, as businesses seek to improve productivity and reduce operational costs. Overall, the Global Roll-to-roll Flatbed Die-cutting Machine Market is poised for significant growth, driven by the increasing demand for high-quality and efficient cutting solutions across various sectors.

| Report Metric | Details |

| Report Name | Roll-to-roll Flatbed Die-cutting Machine Market |

| Accounted market size in year | US$ 66.34 million |

| Forecasted market size in 2031 | US$ 88.12 million |

| CAGR | 4.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ruian Daqiao Packaging Machinery Co., Ltd., Zhejiang Feida Machinery Co., Ltd., Teneth, BOBST, Vicut, BW Papersystems, U-Pack International Ltd, RK LABLE PRINTING MACHINERY PVT LTD, Wenzhou Mingliang Paper Plate Machinery Co., Ltd., Guangya Machinery Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |