What is Global Vertical Hydraulic Tapping Machine Market?

The Global Vertical Hydraulic Tapping Machine Market refers to the industry focused on the production and distribution of machines designed for creating threads inside holes, a process known as tapping. These machines are vertical in orientation and use hydraulic power to perform their tasks, which makes them highly efficient and capable of handling heavy-duty operations. The market encompasses a wide range of industries that require precise and reliable tapping solutions, such as automotive, aerospace, and construction machinery. The demand for these machines is driven by the need for high-quality threading in manufacturing processes, which is crucial for ensuring the integrity and performance of assembled products. As industries continue to advance and require more sophisticated machinery, the market for vertical hydraulic tapping machines is expected to grow, offering innovative solutions to meet the evolving needs of manufacturers worldwide. The machines are valued for their ability to deliver consistent results, reduce manual labor, and enhance productivity, making them an essential component in modern manufacturing environments. With technological advancements and increasing industrialization, the Global Vertical Hydraulic Tapping Machine Market is poised for significant growth, catering to the diverse needs of various sectors.

Standard Vertical, High-Power Heavy-Duty Vertical in the Global Vertical Hydraulic Tapping Machine Market:

In the Global Vertical Hydraulic Tapping Machine Market, two primary types of machines are prevalent: Standard Vertical and High-Power Heavy-Duty Vertical machines. Standard Vertical machines are designed for general-purpose tapping applications. They are typically used in industries where the demand for threading is moderate, and the materials being tapped are not excessively hard or thick. These machines are known for their versatility and ease of use, making them suitable for small to medium-sized enterprises that require reliable tapping solutions without the need for heavy-duty capabilities. Standard Vertical machines are equipped with features that allow for precise control over the tapping process, ensuring high-quality threads and minimizing the risk of errors. They are often used in applications where speed and efficiency are important, but the workload does not require the robust power of heavy-duty machines. On the other hand, High-Power Heavy-Duty Vertical machines are built to handle more demanding tasks. These machines are designed for industries that require tapping of hard materials or large volumes of workpieces. They are equipped with powerful hydraulic systems that provide the necessary force to tap through tough materials, such as steel or titanium, which are commonly used in the aerospace and automotive industries. High-Power Heavy-Duty Vertical machines are essential for manufacturers that need to maintain high production rates while ensuring the durability and precision of their products. These machines are often used in large-scale manufacturing operations where the quality and consistency of threads are critical to the overall performance of the final product. The choice between Standard Vertical and High-Power Heavy-Duty Vertical machines depends largely on the specific needs of the industry and the materials being worked with. While Standard Vertical machines offer flexibility and ease of use, High-Power Heavy-Duty Vertical machines provide the strength and reliability needed for more challenging applications. Both types of machines play a crucial role in the Global Vertical Hydraulic Tapping Machine Market, catering to a wide range of industries and applications. As technology continues to advance, these machines are expected to evolve, offering even greater efficiency and precision to meet the growing demands of modern manufacturing.

Automotive, Aerospace, Construction Machinery, Others in the Global Vertical Hydraulic Tapping Machine Market:

The Global Vertical Hydraulic Tapping Machine Market finds extensive usage across various industries, including automotive, aerospace, construction machinery, and others. In the automotive industry, these machines are essential for creating precise threads in engine components, transmission parts, and other critical assemblies. The ability to produce high-quality threads is crucial for ensuring the performance and reliability of vehicles, as even minor defects can lead to significant issues in operation. Vertical hydraulic tapping machines provide the precision and consistency needed to meet the stringent quality standards of the automotive industry, making them indispensable in the manufacturing process. In the aerospace sector, the demand for vertical hydraulic tapping machines is driven by the need for high-strength, lightweight components. Aerospace manufacturers require machines that can handle the unique challenges of tapping materials like titanium and aluminum, which are commonly used in aircraft construction. The precision and power of vertical hydraulic tapping machines make them ideal for producing the intricate threads needed in aerospace components, ensuring the safety and performance of aircraft. In the construction machinery industry, these machines are used to create threads in heavy equipment parts, such as hydraulic cylinders and structural components. The durability and reliability of construction machinery are paramount, and high-quality threads are essential for maintaining the integrity of these machines under demanding conditions. Vertical hydraulic tapping machines provide the necessary force and precision to produce threads that can withstand the rigors of construction work, contributing to the longevity and performance of the equipment. Beyond these industries, vertical hydraulic tapping machines are also used in various other sectors, including electronics, medical devices, and general manufacturing. In electronics, they are used to create threads in components that require precise assembly, while in the medical field, they are essential for producing threads in surgical instruments and implants. The versatility and efficiency of vertical hydraulic tapping machines make them valuable tools in any industry that requires high-quality threading solutions. As industries continue to evolve and demand more advanced manufacturing capabilities, the Global Vertical Hydraulic Tapping Machine Market is expected to grow, providing innovative solutions to meet the diverse needs of manufacturers worldwide.

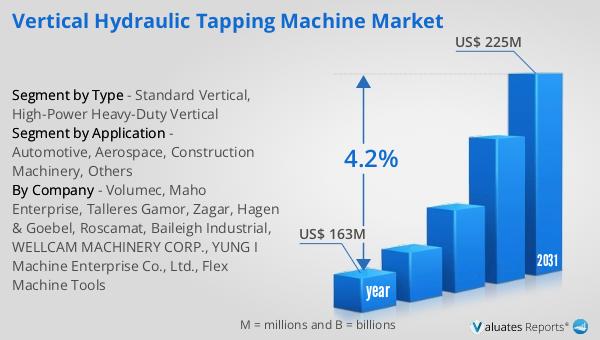

Global Vertical Hydraulic Tapping Machine Market Outlook:

The global market for Vertical Hydraulic Tapping Machines was valued at $163 million in 2024, with projections indicating it will reach approximately $225 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. This upward trend highlights the increasing demand for these machines across various industries, driven by the need for efficient and precise tapping solutions. The market's expansion is fueled by advancements in technology, which have enhanced the capabilities and performance of vertical hydraulic tapping machines, making them more appealing to manufacturers seeking to improve their production processes. As industries continue to advance and require more sophisticated machinery, the demand for vertical hydraulic tapping machines is expected to rise, contributing to the market's growth. The projected increase in market size reflects the growing importance of these machines in modern manufacturing environments, where precision and efficiency are paramount. With the continued development of new materials and manufacturing techniques, the Global Vertical Hydraulic Tapping Machine Market is poised for significant growth, offering innovative solutions to meet the evolving needs of manufacturers worldwide. This growth trajectory underscores the critical role that vertical hydraulic tapping machines play in enhancing productivity and ensuring the quality of threaded components across various industries.

| Report Metric | Details |

| Report Name | Vertical Hydraulic Tapping Machine Market |

| Accounted market size in year | US$ 163 million |

| Forecasted market size in 2031 | US$ 225 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Volumec, Maho Enterprise, Talleres Gamor, Zagar, Hagen & Goebel, Roscamat, Baileigh Industrial, WELLCAM MACHINERY CORP., YUNG I Machine Enterprise Co., Ltd., Flex Machine Tools |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |