What is Global Electronic Torsion Testing Machine Market?

The Global Electronic Torsion Testing Machine Market is a specialized segment within the broader testing equipment industry, focusing on devices that measure the torsional strength of materials. These machines are crucial for determining how materials will perform under twisting forces, which is essential for ensuring the safety and reliability of products in various industries. The market for these machines is driven by the increasing demand for high-quality materials that can withstand significant torsional stress, particularly in sectors like automotive, aerospace, and construction. As industries continue to innovate and develop new materials, the need for precise and reliable torsion testing becomes even more critical. The market is characterized by a range of machines that vary in their maximum torque capacities, catering to different testing requirements. With advancements in technology, electronic torsion testing machines have become more sophisticated, offering enhanced accuracy, ease of use, and data analysis capabilities. This has led to their widespread adoption across the globe, as manufacturers seek to ensure their products meet stringent quality standards. The market is expected to continue growing as industries place greater emphasis on material performance and safety.

Maximum Torque < 1000 Nm, Maximum Torque 1000–3000 Nm, Maximum Torque > 3000 Nm in the Global Electronic Torsion Testing Machine Market:

In the Global Electronic Torsion Testing Machine Market, machines are categorized based on their maximum torque capacities, which determine the range of applications they can handle. Machines with a maximum torque of less than 1000 Nm are typically used for testing smaller components and materials that do not require high levels of torsional force. These machines are ideal for industries where precision and accuracy are paramount, such as in the testing of small mechanical parts, electronic components, and delicate materials. They are often used in research and development settings where new materials are being tested for their torsional properties. On the other hand, machines with a maximum torque capacity of 1000–3000 Nm are designed for medium-sized components and materials. These machines are versatile and can be used in a variety of industries, including automotive and aerospace, where components are subjected to moderate levels of torsional stress. They provide a balance between power and precision, making them suitable for a wide range of testing applications. Finally, machines with a maximum torque capacity of over 3000 Nm are used for testing large components and materials that require significant torsional force. These machines are essential in industries such as construction and heavy machinery, where materials must withstand extreme conditions. They are capable of testing the torsional strength of large beams, shafts, and other structural components, ensuring they meet safety and performance standards. The demand for these high-capacity machines is driven by the need for robust materials that can perform reliably under heavy loads. As industries continue to push the boundaries of material performance, the need for advanced torsion testing machines with higher torque capacities is expected to grow.

Aerospace, Automotive, Biomedical, Others in the Global Electronic Torsion Testing Machine Market:

The Global Electronic Torsion Testing Machine Market finds extensive usage across various industries, including aerospace, automotive, biomedical, and others, due to its ability to accurately measure the torsional strength of materials. In the aerospace industry, these machines are crucial for testing the torsional properties of materials used in aircraft components, such as wings, fuselage, and engine parts. Ensuring that these components can withstand the torsional forces they will encounter during flight is essential for the safety and reliability of aircraft. In the automotive industry, torsion testing machines are used to evaluate the performance of materials used in vehicle components, such as drive shafts, axles, and suspension systems. These machines help manufacturers ensure that their vehicles can handle the torsional stresses encountered during operation, contributing to the overall safety and performance of the vehicle. In the biomedical field, torsion testing machines are used to test the torsional strength of materials used in medical devices and implants, such as bone screws and prosthetic joints. This is crucial for ensuring that these devices can withstand the forces they will encounter in the human body, providing patients with safe and reliable solutions. Beyond these industries, torsion testing machines are also used in sectors such as construction, electronics, and consumer goods, where the torsional properties of materials are critical to product performance and safety. As industries continue to innovate and develop new materials, the demand for precise and reliable torsion testing is expected to grow, driving the expansion of the Global Electronic Torsion Testing Machine Market.

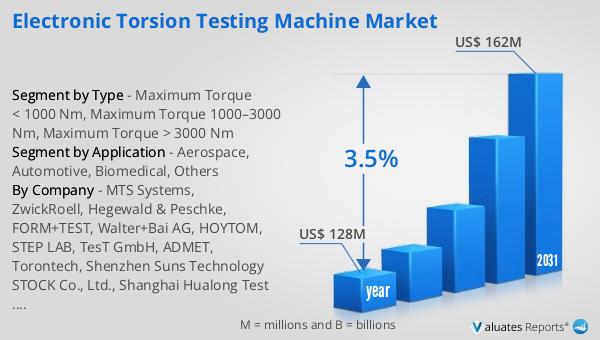

Global Electronic Torsion Testing Machine Market Outlook:

The global market for Electronic Torsion Testing Machines was valued at $128 million in 2024 and is anticipated to grow to a revised size of $162 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.5% over the forecast period. This growth is indicative of the increasing demand for torsion testing machines across various industries, driven by the need for high-quality materials that can withstand significant torsional stress. As industries continue to innovate and develop new materials, the importance of precise and reliable torsion testing becomes even more critical. The market's expansion is supported by advancements in technology, which have led to the development of more sophisticated electronic torsion testing machines. These machines offer enhanced accuracy, ease of use, and data analysis capabilities, making them an attractive option for manufacturers seeking to ensure their products meet stringent quality standards. The projected growth of the market reflects the ongoing emphasis on material performance and safety, as well as the increasing adoption of torsion testing machines across the globe. As industries continue to place greater emphasis on these factors, the demand for electronic torsion testing machines is expected to rise, driving further growth in the market.

| Report Metric | Details |

| Report Name | Electronic Torsion Testing Machine Market |

| Accounted market size in year | US$ 128 million |

| Forecasted market size in 2031 | US$ 162 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MTS Systems, ZwickRoell, Hegewald & Peschke, FORM+TEST, Walter+Bai AG, HOYTOM, STEP LAB, TesT GmbH, ADMET, Torontech, Shenzhen Suns Technology STOCK Co., Ltd., Shanghai Hualong Test Instruments Co., Ltd., Shenzhen Wance Testing Machine Co., Ltd., Changchun Xinte Testing Machine Co., Ltd., HST Group, Lishi(Shanghai) Instruments Co., Ltd., Jinan Tianchen Testing Machine Manufacturing Co., Ltd., Jinan Xinshidai Assaying Instrument Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |