What is Global TGV Hole Filling Electroplating Machine Market?

The Global TGV Hole Filling Electroplating Machine Market is a specialized segment within the broader electroplating industry, focusing on the technology used to fill through-glass vias (TGVs) with metal. TGVs are tiny holes in glass substrates that are filled with conductive materials to create electrical connections in various electronic components. The electroplating machines designed for this purpose are crucial in ensuring the efficient and precise filling of these vias, which is essential for the performance and reliability of the final electronic products. These machines are used extensively in industries that require high-density interconnections, such as semiconductor manufacturing, advanced packaging, and micro-electromechanical systems (MEMS). The market for these machines is driven by the increasing demand for miniaturized electronic devices and the need for advanced packaging solutions that offer better performance and efficiency. As technology continues to evolve, the demand for TGV hole filling electroplating machines is expected to grow, driven by innovations in electronics and the increasing complexity of electronic components.

Automatic, Manual in the Global TGV Hole Filling Electroplating Machine Market:

In the Global TGV Hole Filling Electroplating Machine Market, machines can be broadly categorized into automatic and manual types, each serving different needs and preferences of manufacturers. Automatic machines are designed to offer high precision and efficiency, making them ideal for large-scale production environments where consistency and speed are crucial. These machines are equipped with advanced features such as automated control systems, real-time monitoring, and feedback mechanisms that ensure optimal performance and minimal human intervention. The automation in these machines allows for precise control over the electroplating process, ensuring uniform filling of TGVs and reducing the risk of defects. This is particularly important in industries like semiconductor manufacturing, where even minor inconsistencies can lead to significant performance issues. On the other hand, manual electroplating machines are typically used in smaller production settings or for specialized applications where flexibility and customization are more important than speed. These machines require skilled operators to manage the electroplating process, allowing for greater control over specific parameters and the ability to make adjustments on the fly. While they may not offer the same level of efficiency as automatic machines, manual machines can be more cost-effective for smaller operations or for applications that require a high degree of customization. The choice between automatic and manual machines often depends on the specific needs of the manufacturer, including production volume, budget, and the level of precision required. In recent years, there has been a growing trend towards automation in the electroplating industry, driven by the need for higher efficiency and the increasing complexity of electronic components. However, manual machines still hold a significant place in the market, particularly in niche applications where their flexibility and adaptability are valued. As the demand for advanced electronic devices continues to rise, the Global TGV Hole Filling Electroplating Machine Market is expected to see continued growth, with both automatic and manual machines playing important roles in meeting the diverse needs of manufacturers.

Semiconductor Advanced Packaging, Memory, MEMS, Optical Communications, Others in the Global TGV Hole Filling Electroplating Machine Market:

The Global TGV Hole Filling Electroplating Machine Market finds its applications across various sectors, including semiconductor advanced packaging, memory, MEMS, optical communications, and others. In semiconductor advanced packaging, these machines are essential for creating high-density interconnections that are crucial for the performance and miniaturization of electronic devices. The ability to fill TGVs with precision ensures that the electrical connections are reliable and efficient, which is vital for the functionality of advanced semiconductor packages. In the memory sector, TGV hole filling electroplating machines are used to enhance the performance and capacity of memory devices. By ensuring precise and uniform filling of TGVs, these machines help in creating memory devices that are faster and more efficient, meeting the growing demand for high-performance computing and data storage solutions. In the field of MEMS, these machines play a critical role in the fabrication of micro-scale devices that are used in a wide range of applications, from sensors to actuators. The precision offered by TGV hole filling electroplating machines is crucial in ensuring the functionality and reliability of MEMS devices, which are often used in critical applications such as automotive and medical devices. In optical communications, these machines are used to create high-performance optical components that are essential for the transmission of data over long distances. The ability to create precise and reliable electrical connections through TGVs is crucial in ensuring the efficiency and reliability of optical communication systems. Beyond these specific sectors, TGV hole filling electroplating machines are also used in various other applications where high-density interconnections and miniaturization are required. As technology continues to advance and the demand for smaller, more efficient electronic devices grows, the applications for these machines are expected to expand, driving further growth in the Global TGV Hole Filling Electroplating Machine Market.

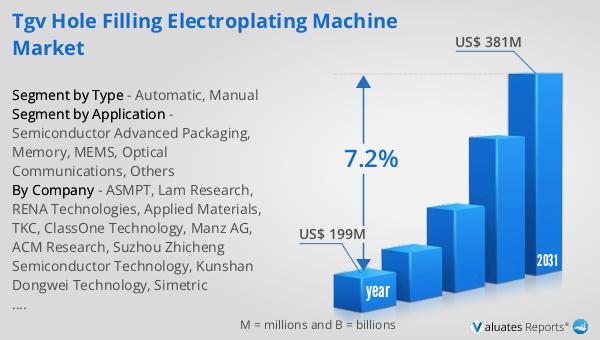

Global TGV Hole Filling Electroplating Machine Market Outlook:

The global market for TGV Hole Filling Electroplating Machines was valued at approximately $199 million in 2024. This market is anticipated to grow significantly, reaching an estimated value of $381 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 7.2% over the forecast period. The increasing demand for advanced electronic devices and the need for efficient and reliable interconnection solutions are key factors driving this growth. As industries such as semiconductor manufacturing, MEMS, and optical communications continue to evolve, the demand for TGV hole filling electroplating machines is expected to rise. These machines play a crucial role in ensuring the performance and reliability of electronic components, making them an essential part of the manufacturing process. The market's growth is also supported by technological advancements in electroplating machines, which offer improved precision, efficiency, and automation. As manufacturers seek to enhance their production capabilities and meet the growing demand for miniaturized electronic devices, the Global TGV Hole Filling Electroplating Machine Market is poised for continued expansion. This growth presents significant opportunities for manufacturers and suppliers in the industry, as they work to develop innovative solutions that meet the evolving needs of their customers.

| Report Metric | Details |

| Report Name | TGV Hole Filling Electroplating Machine Market |

| Accounted market size in year | US$ 199 million |

| Forecasted market size in 2031 | US$ 381 million |

| CAGR | 7.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ASMPT, Lam Research, RENA Technologies, Applied Materials, TKC, ClassOne Technology, Manz AG, ACM Research, Suzhou Zhicheng Semiconductor Technology, Kunshan Dongwei Technology, Simetric Semiconductor, Sukos Semiconductor Equipment, Jimsi Semiconductor Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |